Continuous synthesis for oseltamivir phosphate

A technology of oseltamivir phosphate and its synthesis method, which is applied in the field of continuous oseltamivir phosphate compound and its preparation, can solve the problems of cumbersome preparation steps, long production cycle and high cost, and achieve simple pipeline route and reduce time , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

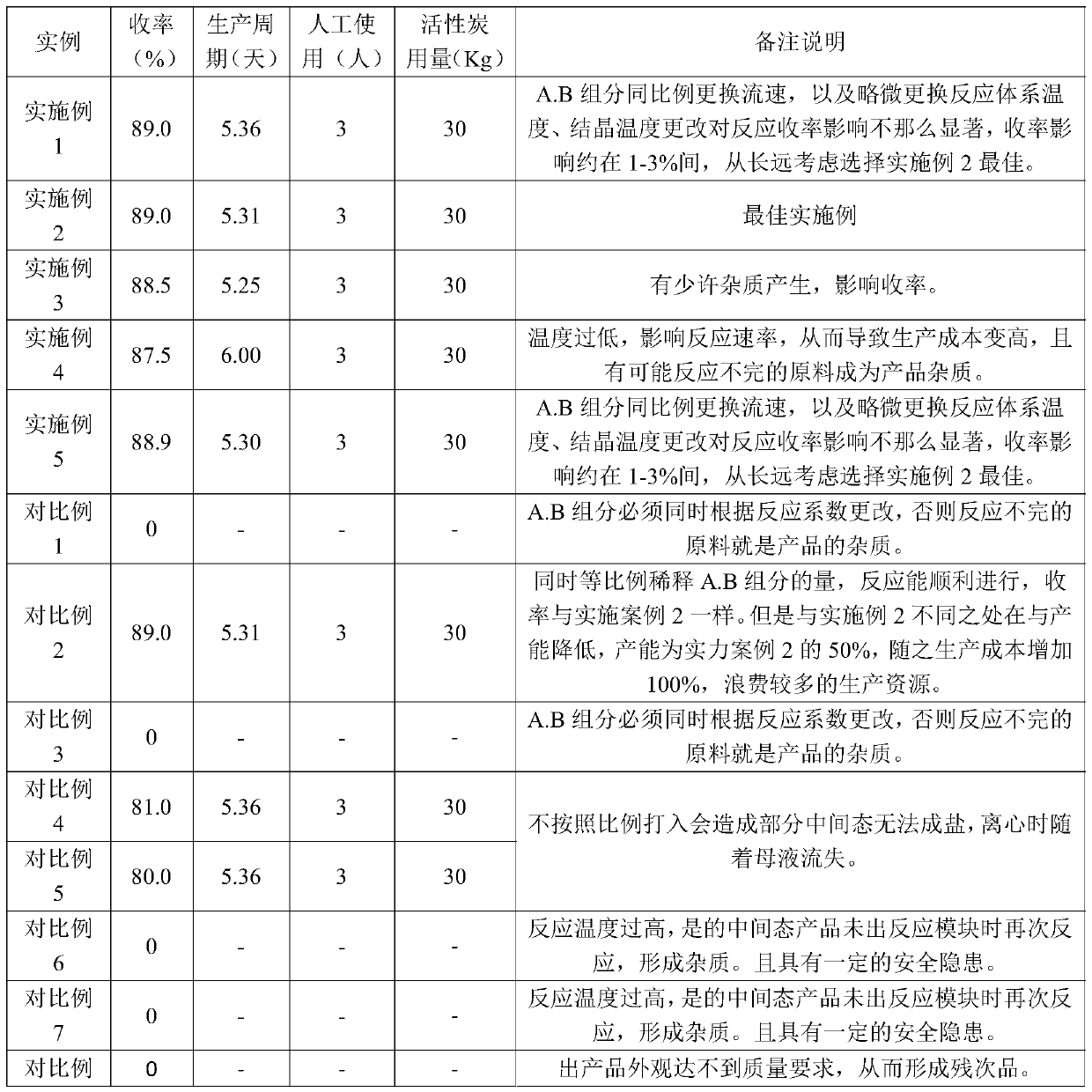

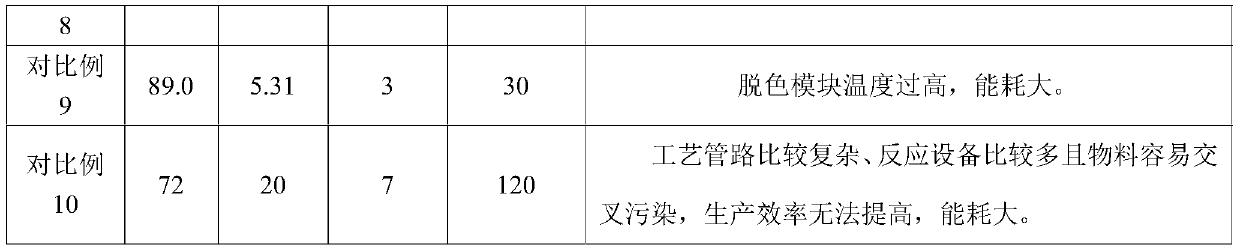

Examples

Embodiment 1

[0059] A synthetic method for continuous oseltamivir phosphate, comprising the following steps:

[0060] (1) Configuration solution: configure solution A and solution B respectively;

[0061] Solution A is a dehydrated ethanol solution of 35.52% by weight of intermediate 11 composed of 1074.00kg intermediate 11, 3023.65kg dehydrated alcohol and 0.20kg triphenylphosphine;

[0062] Solution B is the dehydrated ethanol solution of 1.3-dimethylbarbituric acid of 14.14% by weight of 427.54kg1.3-dimethylbarbituric acid, 3023.65kg dehydrated alcohol and 0.20kg triphenylphosphine composition ;

[0063] After adding solution A and solution B to the mixing module at the same time for mixing, mix to obtain mixture C; wherein the solution

[0064] A and solution B are transported by a metering diaphragm pump, and the transport flow rate is 0.99L / min;

[0065] (2) Reaction: transfer the mixture C to the reaction module, and the reaction module is loaded with a mesh-shaped high-performan...

Embodiment 2

[0074] A synthetic method for continuous oseltamivir phosphate, comprising the following steps:

[0075] (1) Configuration solution: configure solution A and solution B respectively;

[0076] Solution A is a dehydrated ethanol solution of 35.52% by weight of intermediate 11 composed of 1074.00kg intermediate 11, 3023.65kg dehydrated alcohol and 0.20kg triphenylphosphine;

[0077] Solution B is the dehydrated ethanol solution of 1.3-dimethylbarbituric acid of 14.14% by weight of 427.54kg1.3-dimethylbarbituric acid, 3023.65kg dehydrated alcohol and 0.20kg triphenylphosphine composition ;

[0078] After adding solution A and solution B to the mixing module at the same time for mixing, mix to obtain mixture C; wherein the solution

[0079] A and solution B are transported by a metering diaphragm pump, and the transport flow rate is 1.00L / min;

[0080] (2) Reaction: transfer the mixture C to the reaction module, and the reaction module is loaded with a mesh-shaped high-performan...

Embodiment 3

[0088] A synthetic method for continuous oseltamivir phosphate, comprising the following steps:

[0089] (1) Configuration solution: configure solution A and solution B respectively;

[0090] Solution A is a dehydrated ethanol solution of 35.52% by weight of intermediate 11 composed of 1074.00kg intermediate 11, 3023.65kg dehydrated alcohol and 0.20kg triphenylphosphine;

[0091] Solution B is the dehydrated ethanol solution of 1.3-dimethylbarbituric acid of 14.14% by weight of 427.54kg1.3-dimethylbarbituric acid, 3023.65kg dehydrated alcohol and 0.20kg triphenylphosphine composition ;

[0092] After adding solution A and solution B to the mixing module at the same time for mixing, mix to obtain mixture C; wherein the solution

[0093] A and solution B are transported by a metering diaphragm pump, and the transport flow rate is 1.01L / min;

[0094] (2) Reaction: transfer the mixture C to the reaction module, and the reaction module is loaded with a mesh-shaped high-performan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com