Full-spectrum borosilicate fluorescent glass and preparation method thereof

A technology of borosilicate and fluorescent glass, which is applied in the field of full-spectrum borosilicate fluorescent glass and its preparation, can solve the problems of no full-spectrum fluorescent glass, difficult doping of red phosphor, easy reaction, etc., and achieve the goal of expanding Type field and application range, simple process, effect of high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] According to the mole percentage of each raw material in the full-spectrum borosilicate fluorescent glass, it is fully mixed according to the proportion of 10% Na2O, 20% ZnO, 30% B2O3, 20% SiO, and 20% MgO, Mix the raw materials evenly and melt them. The melting temperature is 1000°C, and keep warm for 1 hour to obtain molten glass; pour the molten glass into cold water, and perform water quenching to cool down to obtain transparent matrix glass; grind the glass into powder and pass through a 200-mesh sieve .

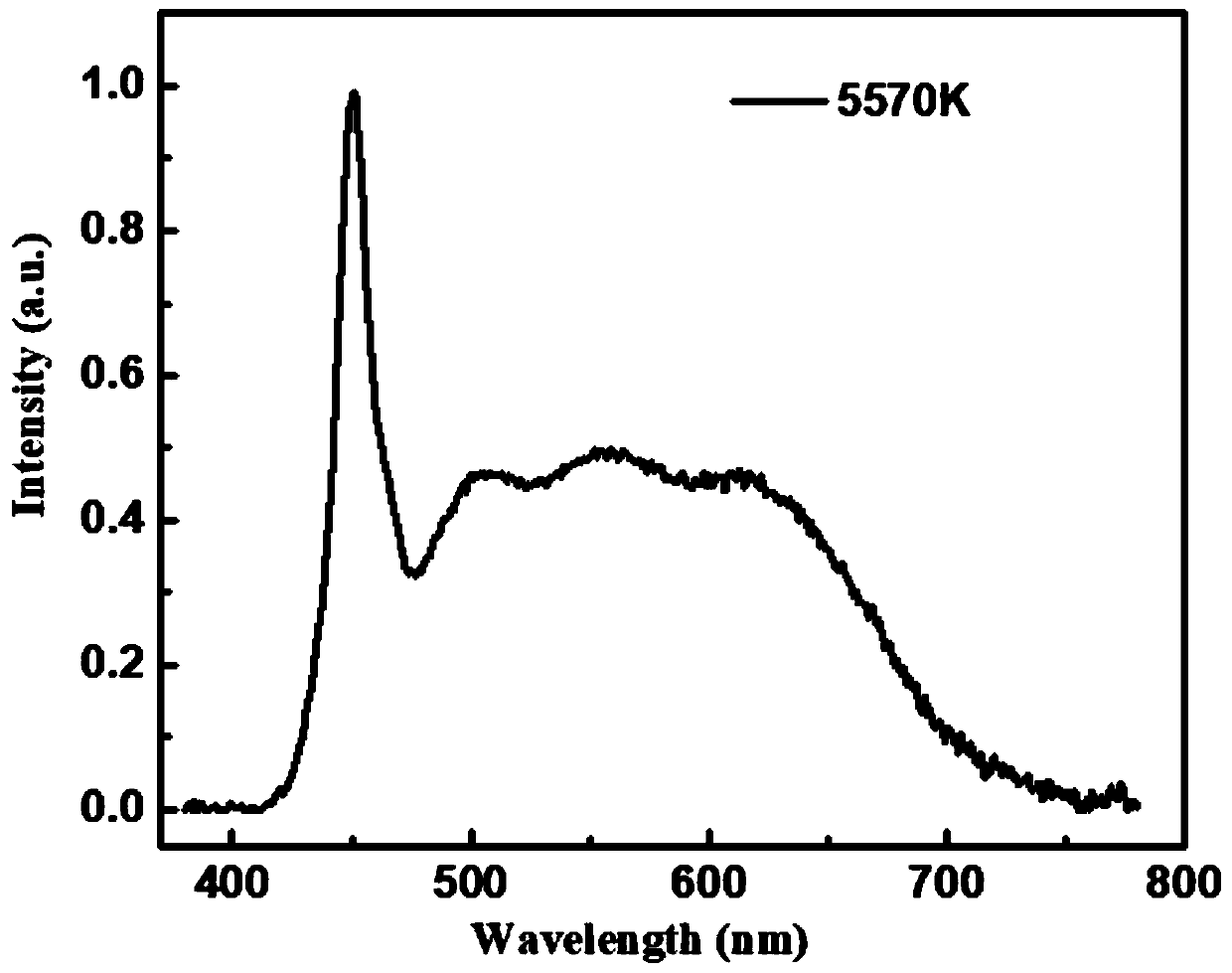

[0033] Among the full-spectrum phosphors, cyan phosphor: green phosphor: red phosphor: 1:1.3:0.3, mixed evenly with the above-mentioned glass powder at a mass ratio of 0.1:1, and sintered in a muffle furnace at a sintering temperature of 600°C. The sintering time is 30 minutes, and then annealing is started at the glass transition temperature Tg temperature, and the temperature is lowered to 20°C at a cooling rate of 5-10°C / hour to obtain a full-spectrum borosili...

Embodiment 2

[0036]According to the mole percentage of each raw material in the full-spectrum borosilicate fluorescent glass, it is fully mixed according to the proportion of 10% Na2O, 20% ZnO, 30% B2O3, 20% SiO, and 20% MgO, Mix the raw materials evenly and melt them. The melting temperature is 1000°C, and keep warm for 1 hour to obtain molten glass; pour the molten glass into cold water, and perform water quenching to cool down to obtain transparent matrix glass; grind the glass into powder and pass through a 200-mesh sieve .

[0037] The molar percentage of each component of the full-spectrum phosphor is: cyan phosphor: green phosphor: red phosphor: 1:1.6:0.3, mixed with the above-mentioned glass powder in a mass ratio of 0.1:1, and sintered in a muffle furnace , the sintering temperature is 600°C, the sintering time is 30min, and then annealing is started at the glass transition temperature Tg temperature, the temperature is lowered to 20°C, and the cooling rate is 5-10°C / hour, and a f...

Embodiment 3

[0040] According to the mole percentage of each raw material in the full-spectrum borosilicate fluorescent glass, it is fully mixed according to the proportion of 10% Na2O, 20% ZnO, 30% B2O3, 20% SiO, and 20% MgO, Mix the raw materials evenly and melt them. The melting temperature is 1000°C, and keep warm for 1 hour to obtain molten glass; pour the molten glass into cold water, and perform water quenching to cool down to obtain transparent matrix glass; grind the glass into powder and pass through a 200-mesh sieve .

[0041] The molar percentage of each component of the full-spectrum phosphor is: cyan phosphor: green phosphor: red phosphor: 1.5: 1.3: 0.3, and the above glass powder is uniformly mixed in a mass ratio of 0.1:1, and sintered in a muffle furnace , the sintering temperature is 600°C, the sintering time is 30min, and then annealing is started at the glass transition temperature Tg temperature, the temperature is lowered to 20°C, and the cooling rate is 5-10°C / hour, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com