Height adjustment assembly for support spring of motor vehicle shock absorber

A height adjustment and support spring technology, which is applied to shock absorbers, vehicle springs, springs, etc., can solve the problems of shortening the service life of height adjustment components, and achieve the effect of improving load distribution and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

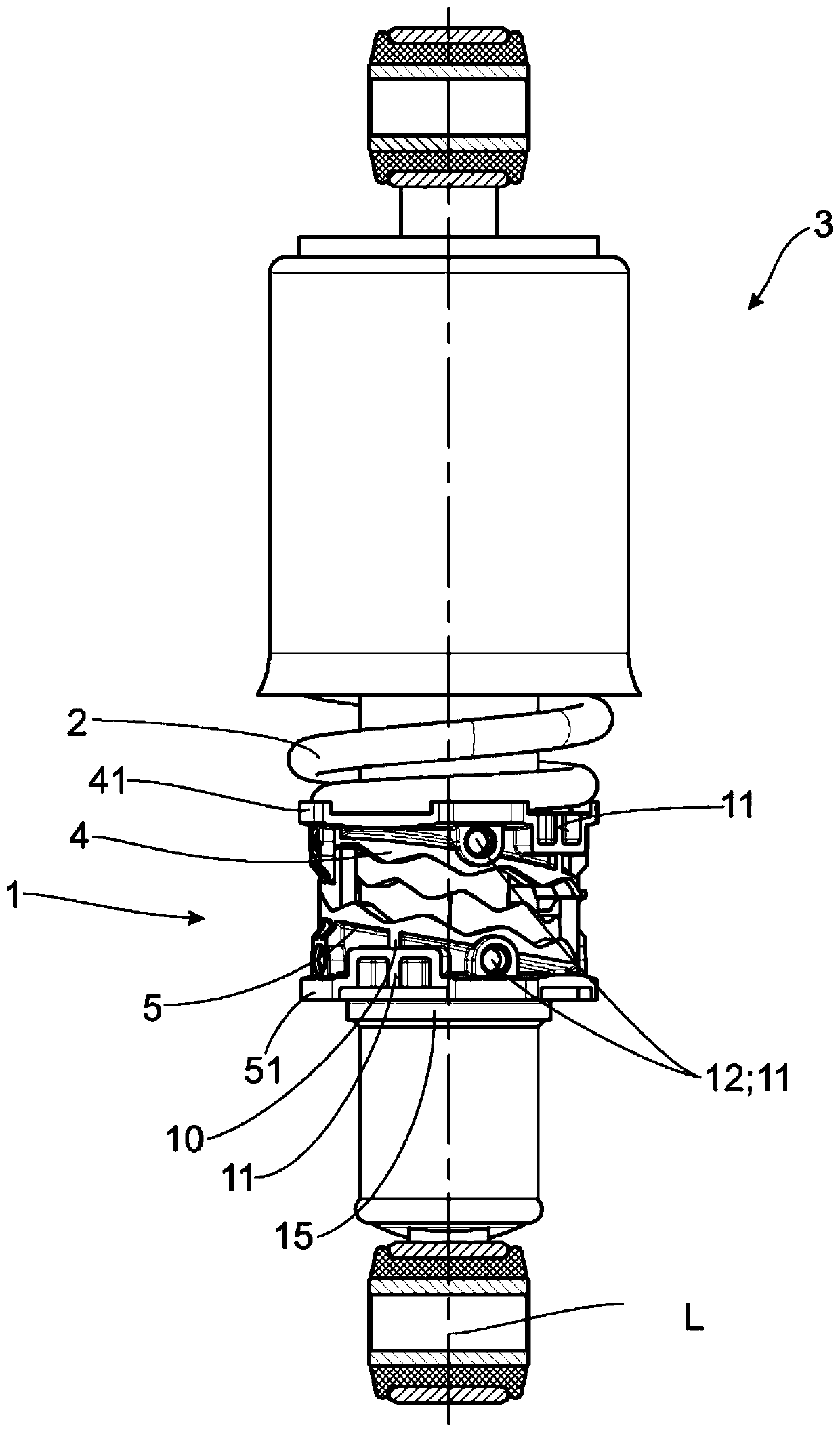

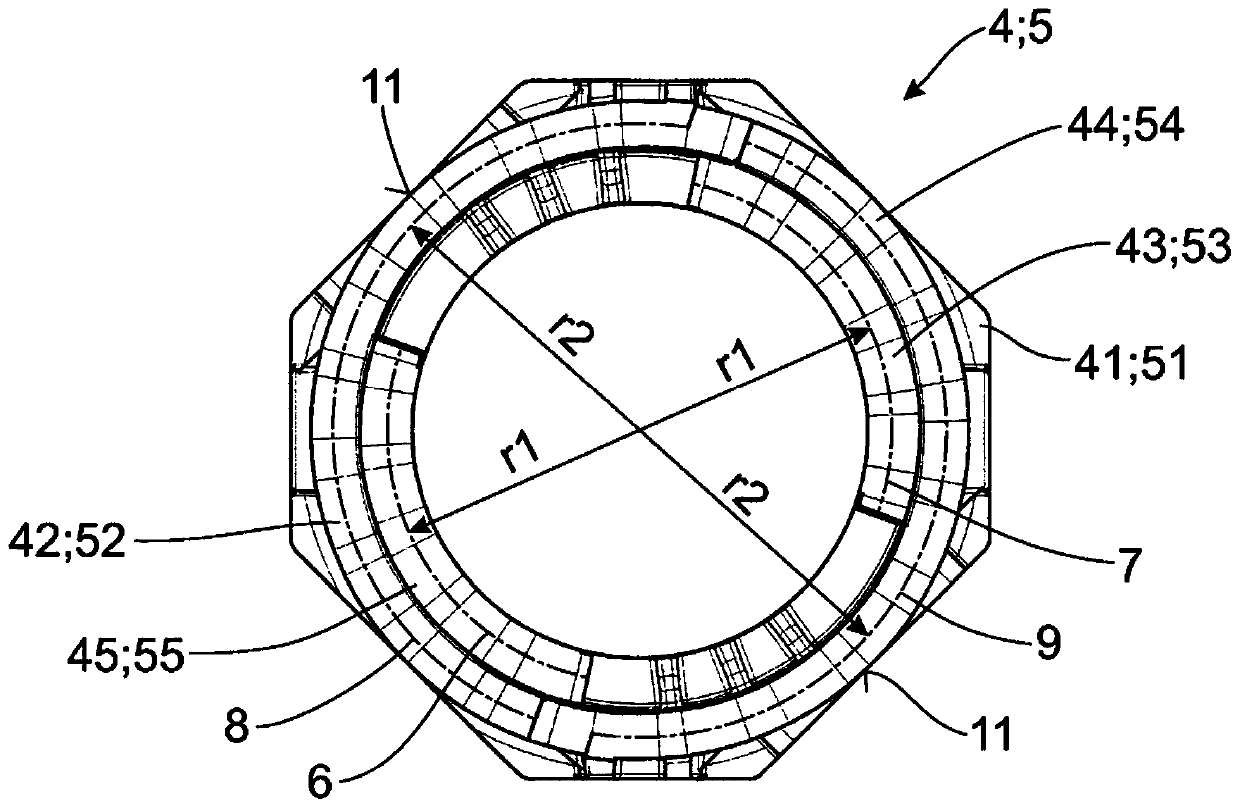

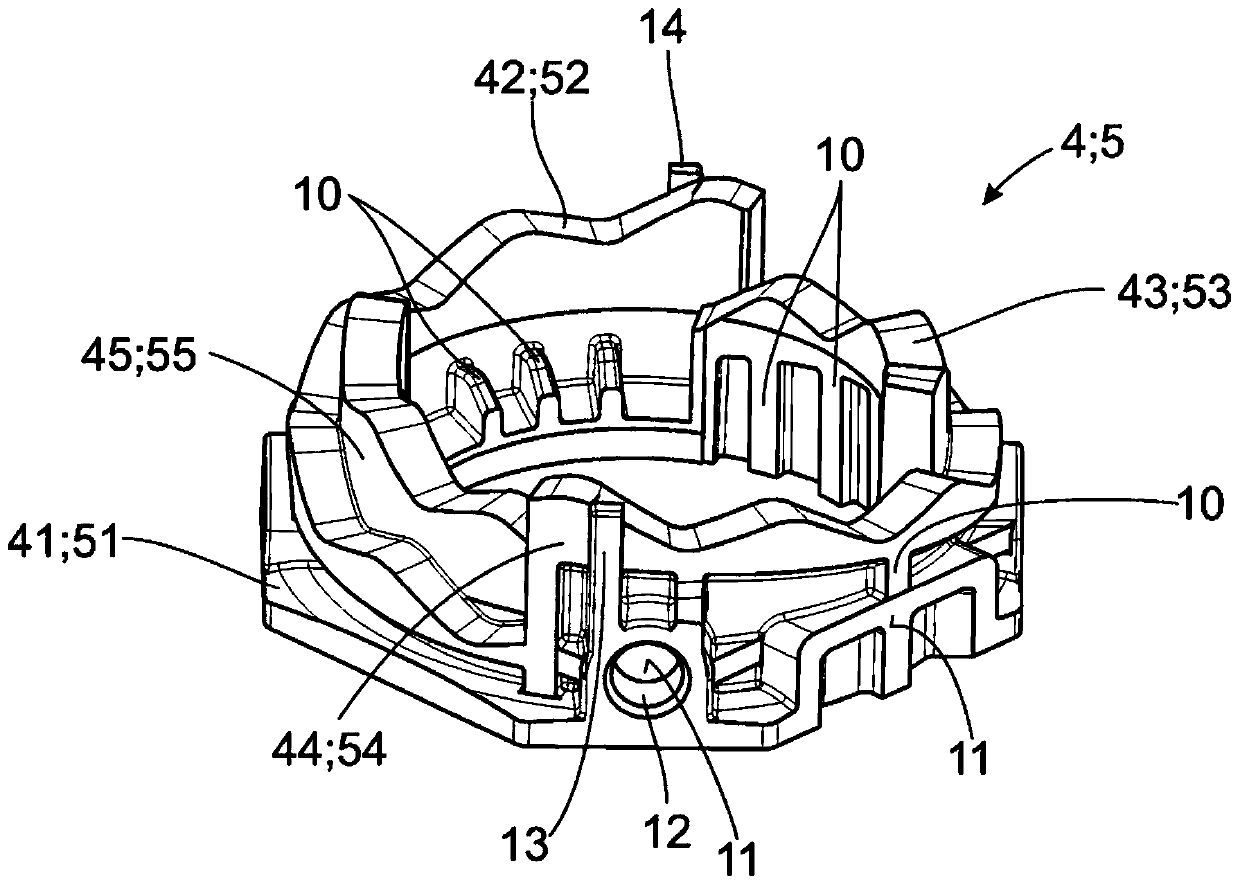

[0022] figure 1 A motor vehicle shock absorber 3 with a height adjustment arrangement 1 according to claim 1 is shown in perspective illustration. The height adjustment assembly 1 comprises a first height adjustment member 4 and a second height adjustment member 5 .

[0023] According to the height adjustment assembly 1 of the present invention in figure 1 , 4 , 5 and 7 are accordingly configured in such a way that the first height adjustment member 4 and the second height adjustment member 5 are designed identically to one another.

[0024] exist figure 1 In the embodiment variant depicted in , the second height adjustment member 5 is supported axially on a torsion locking member 15 which is fixedly connected to the motor vehicle shock absorber. Therefore, the second height adjustment member 5 is axially fixed and prevented from twisting.

[0025] The first height adjustment member 4 is axially supported at the height adjustment member 5 . The two height adjustment memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com