Locking device and method for oil field pumping unit brake device

A brake device and locking device technology, which is applied in mechanical equipment, brake actuators, gear transmission mechanisms, etc., can solve the problems of staff damage, aging, and brake disc immobility, etc., to solve brake sensitivity, increase practicability, non-slip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

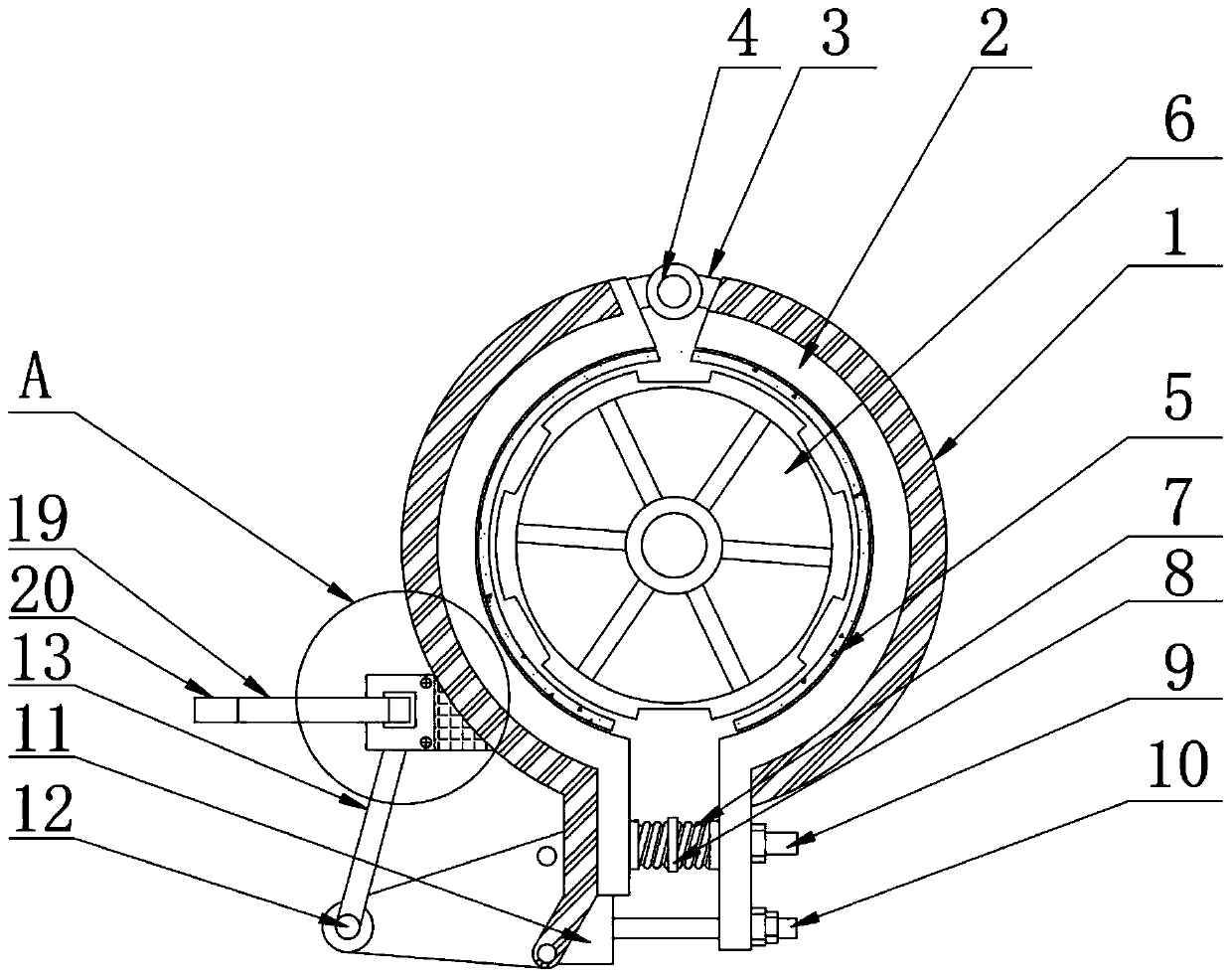

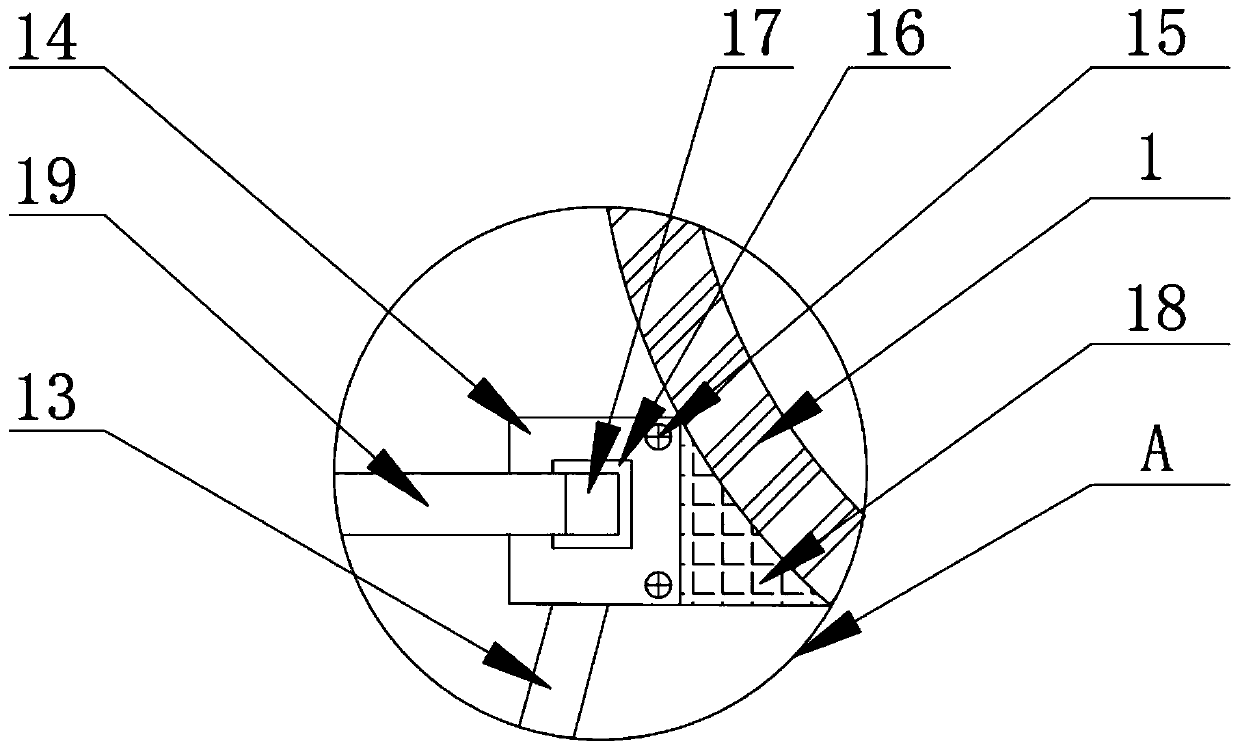

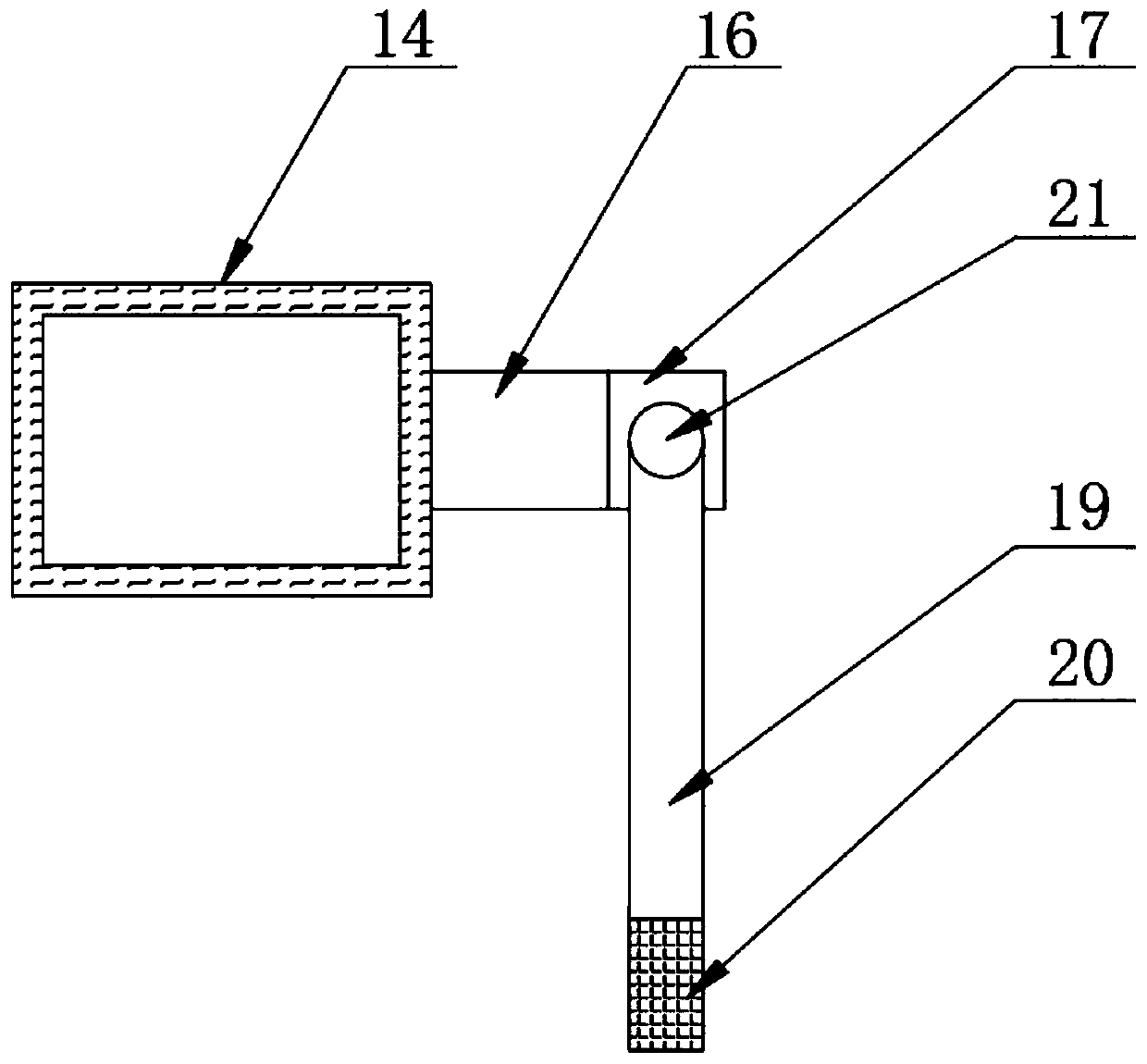

[0037] as attached Figure 1-9 The brake device locking device of the oil pumping unit shown includes a fixed disc 1, a brake disc 2, a movable block 3, a movable wheel 4, and a brake disc 6. The inner wall of the brake disc 2 is fixed with a fastening pad 5, and the brake disc 2 Back-moving spring 7 is movably installed at the bottom of the side, and fixed frame 8 is fixedly installed in the middle part of back-moving spring 7. The bottom of the other side of brake disc 2 is movably connected with spring shaft 9, and the bottom of spring shaft 9 is movably connected with movable shaft 10. The movable plate 11 is arranged on the bottom movable cover of the disc 1, and a connecting shaft 12 is fixedly installed on one side of the movable plate 11. The top of the connecting shaft 12 is welded with a connecting rod 13, and the top of the connecting rod 13 is welded with a locking box 14, and the locking box The surface of 14 is detachably installed with dismounting screw 15, and ...

Embodiment 2

[0056] Specifically compared with Embodiment 1, a positive and negative electric box 1414 is added inside the electric box 141, one end of the switch wire 1412 is fixedly connected to the positive and negative electric box 1414, and the other side of the positive and negative electric box 1414 is fixedly connected to the positive and negative electric wire 1415 , the other end of the positive and negative wire 1415 is fixedly connected with a single-axis motor 1411 .

[0057] Using the above technical means: by installing the forward and reverse electric box 1414 inside the electric box 141, when the single-axis motor 1411 is stopped and started, the positive and negative electric box 1414 is used to transmit the positive and negative currents to the single-axis motor through the positive and negative electric wires 1415 1411, so as to carry out the forward and reverse rotation of the motor shaft of the single-axis motor 1411, avoiding the brake disc 6 from being locked all the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com