Door and window sectional material with light emitting assembly

A technology for light-emitting components and door and window profiles, applied in the field of window profiles, can solve problems such as hidden safety hazards, damage to the lamp body, and affect the appearance, and achieve the effects of convenient repair and maintenance, reasonable space arrangement, and reasonable internal space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

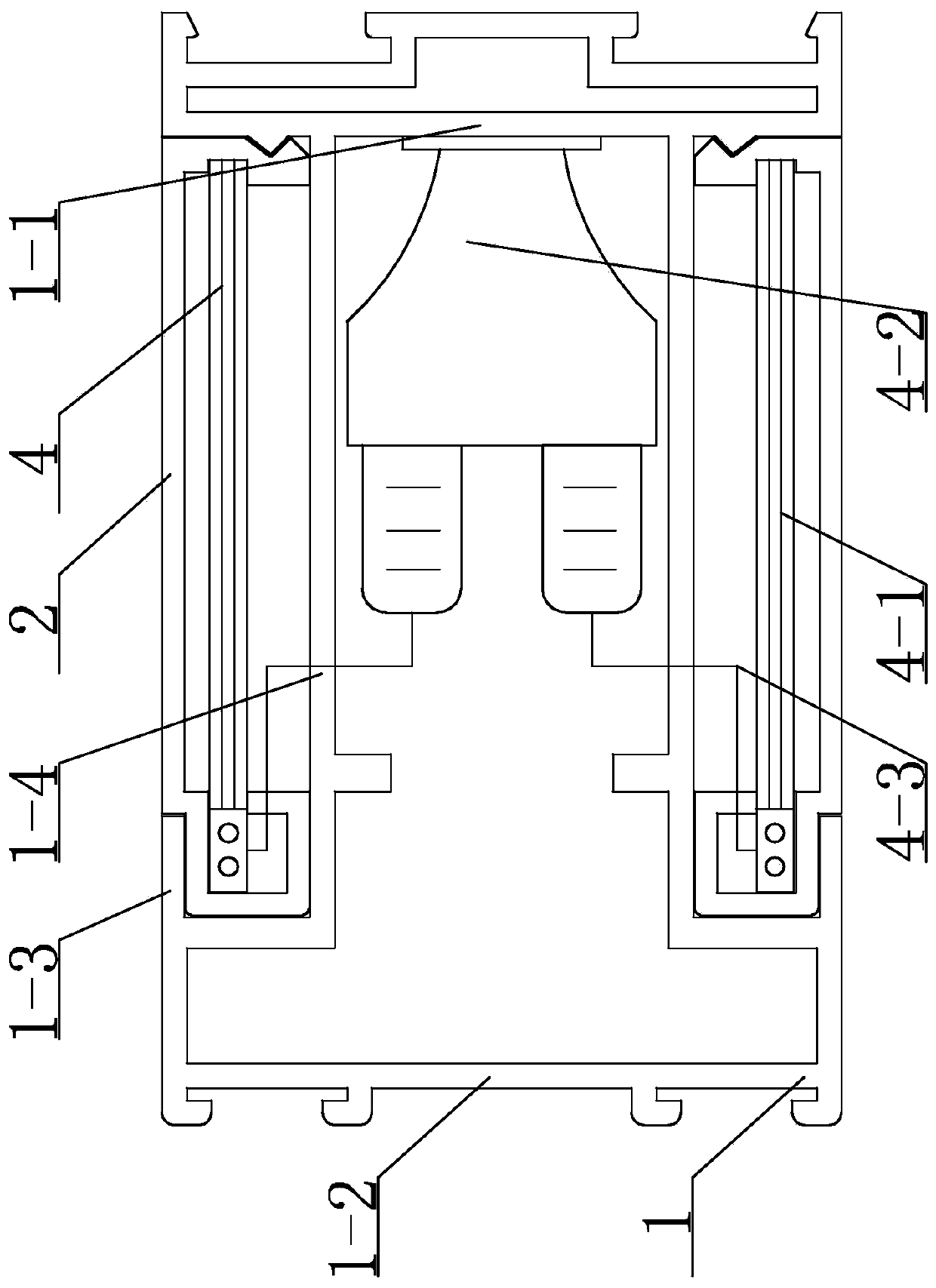

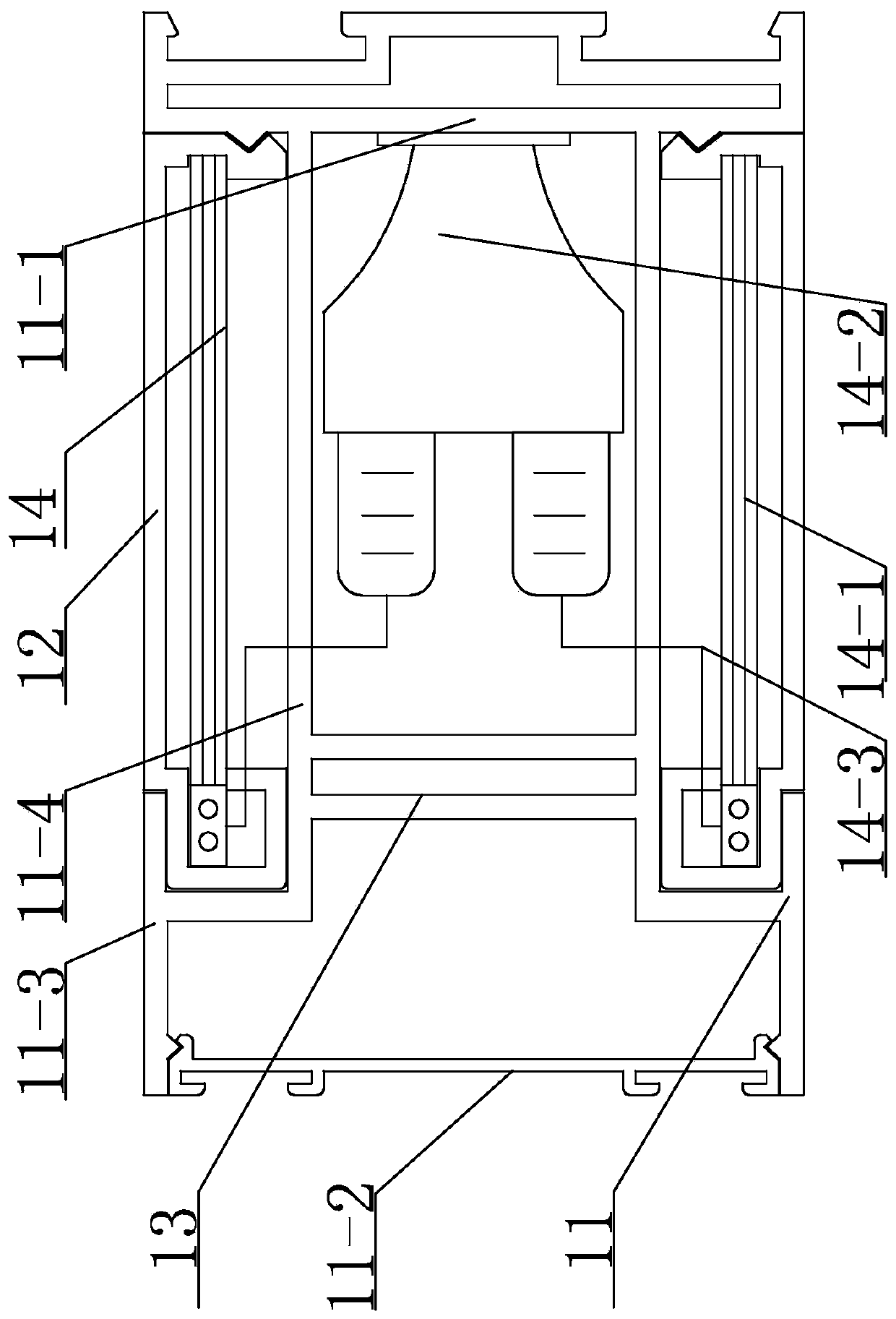

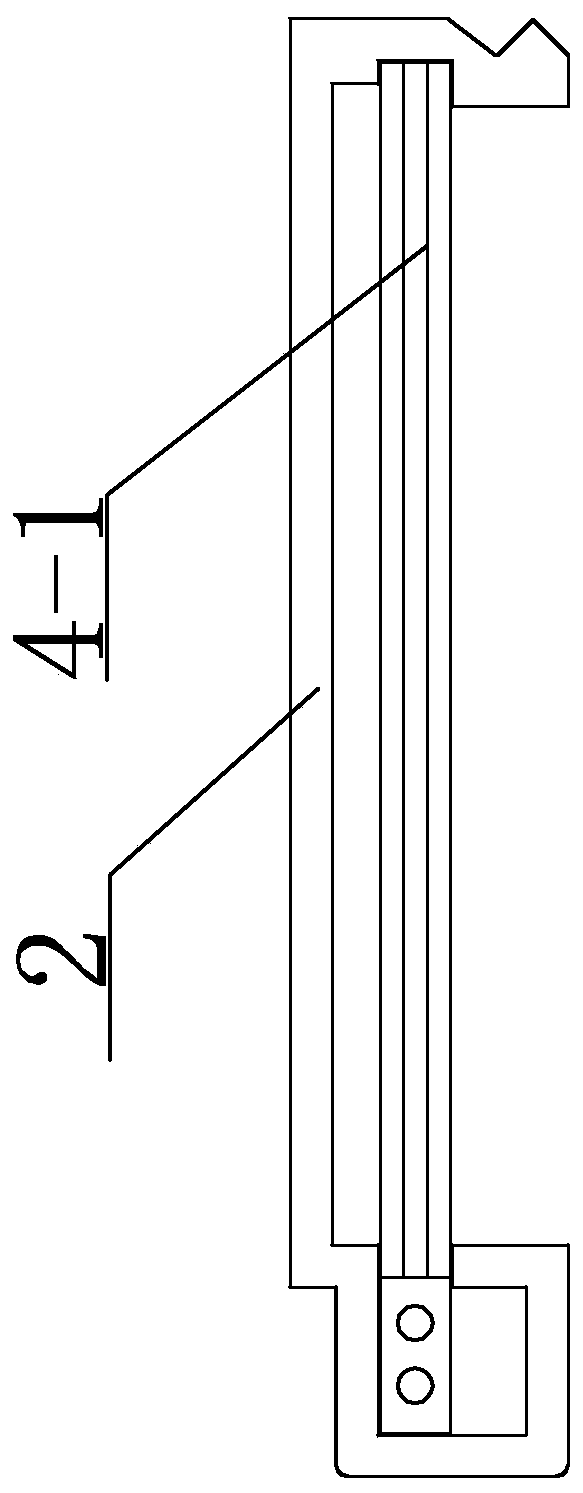

[0017] Specific implementation mode one: combine figure 1 with image 3 Describe this embodiment, a door and window profile with light-emitting components in this embodiment, which includes a first support cavity 1, a first light-emitting component 4 and two first light-transmitting clamps 2; The optical card board 2 includes a first insertion end, a first connection end and a first clamping end, the first insertion end, the first connection end and the first clamping end are integrally arranged, and the outer wall of the first support cavity 1 Two first card board installation grooves are oppositely provided along the length direction, and each first light-transmitting card board 2 is respectively arranged in a first card board installation groove, and the first insertion end of the first light-transmitting card board 2 is installed On one side of the first card board installation groove, the first clamping end of the first light-transmitting card board 2 is clamped on the o...

specific Embodiment approach 2

[0018] Specific implementation mode two: combination figure 1 with image 3 Describe this embodiment, a door and window profile with light-emitting components described in this embodiment, the first support cavity 1 includes a first connection cavity 1-1, a first connection plate 1-2, two first connection cards The plate 1-3 and the two first connecting bent plates 1-4; the first connecting cavity 1-1 and the first connecting plate 1-2 are arranged relatively parallel, and the two first connecting bent plates 1-4 are arranged oppositely at the third Between a connecting cavity 1-1 and the first connecting plate 1-2, one end of each first connecting bent plate 1-4 is respectively fixedly connected to the outer side wall of the first connecting cavity 1-1, and each first The other end of the connecting bent plate 1-4 is fixedly connected to the first connecting plate 1-2 through the first connecting clamping plate 1-3 respectively, and two first bead installations are processed...

specific Embodiment approach 3

[0019] Specific implementation mode three: combination figure 1 with image 3 Describe this embodiment, a door and window profile with light-emitting components described in this embodiment, the first connecting bent plate 1-4 is a right-angled connecting plate, and a flat plate on each first connecting bent plate 1-4 is connected to the first The outer wall of the support cavity 1 is fixedly connected, and the other flat plate on each first connecting bent plate 1-4 is vertically installed on the side of the first connecting clamping plate 1-3, and the first connecting clamping plate 1-3 is close to the first connecting clamping plate 1-3. The distance between one side of the connecting cavity 1-1 is smaller than the distance between the first connecting clamp plate 1-3 and the first connecting plate 1-2, and each first connecting bent plate 1-4 is connected to the first connecting plate 1-4. The outer wall of the clamping plate 1-3 and the first connecting cavity 1-1 forms ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com