Braking system and method for hoisting mechanism of dynamic compaction machine

A technology for hoisting and braking systems of a dynamic compactor, which is applied in the sequence/logic controller for program control, mechanical equipment, soil protection, etc., which can solve the problem of rope disorder or rope bite, insufficient braking speed, and large acceleration value. and other problems, to achieve the effect of small free extension, good braking reliability and stable braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

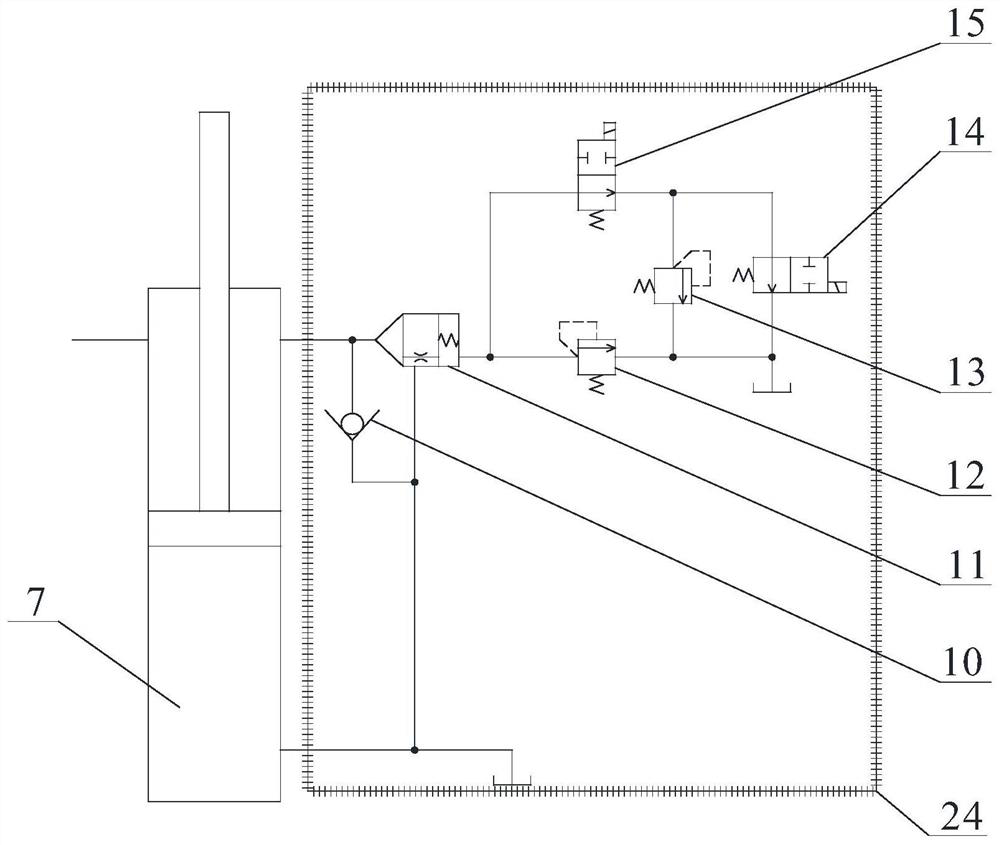

[0036] The braking system of the lifting mechanism of the dynamic compaction machine includes sensors, control systems, and hydraulic control circuits.

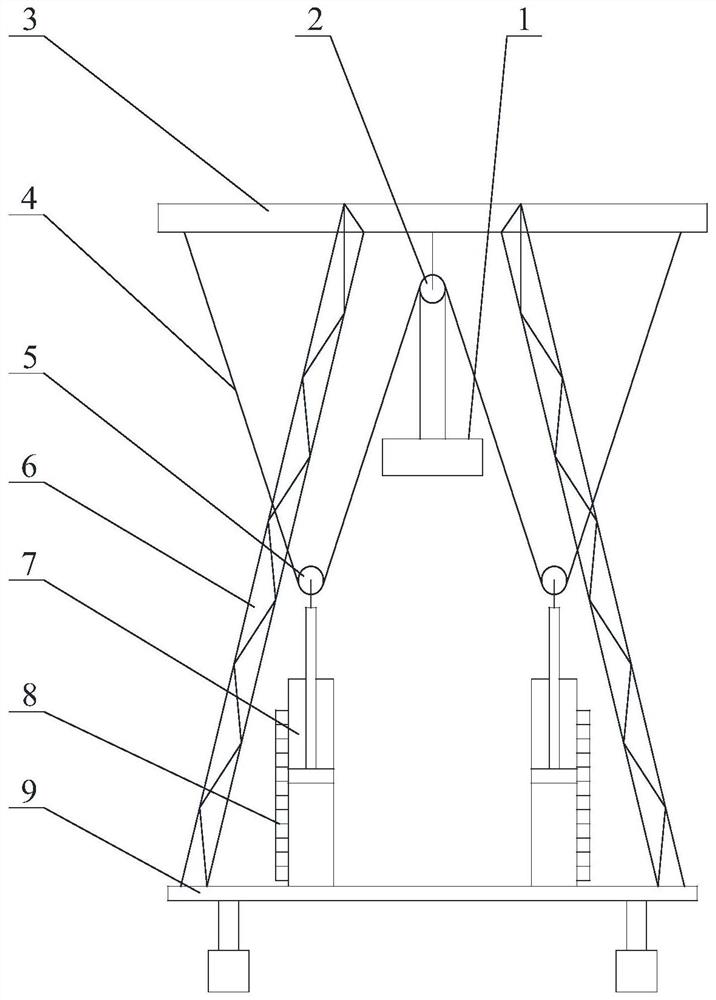

[0037]In order to describe the present invention in more detail, in this embodiment, a detailed description will be given in conjunction with the actual design and use of the dynamic compaction machine of the present invention. The dynamic tamping machine comprises a chassis, a side support, and a top beam, and the four side supports are annularly arranged on the chassis, and the top beam is fixedly connected with the tops of the four side supports. The two lifting cylinders are symmetrically arranged, and the lifting cylinders are installed on the side bracket or the chassis, and can be installed vertically or inclined along the side bracket. The piston rod of the lifting cylinder is connected to the movable pulley, and the fixed pulley is installed on the top beam. One end of the hoisting rope goes around the fixed pulley a...

Embodiment 2

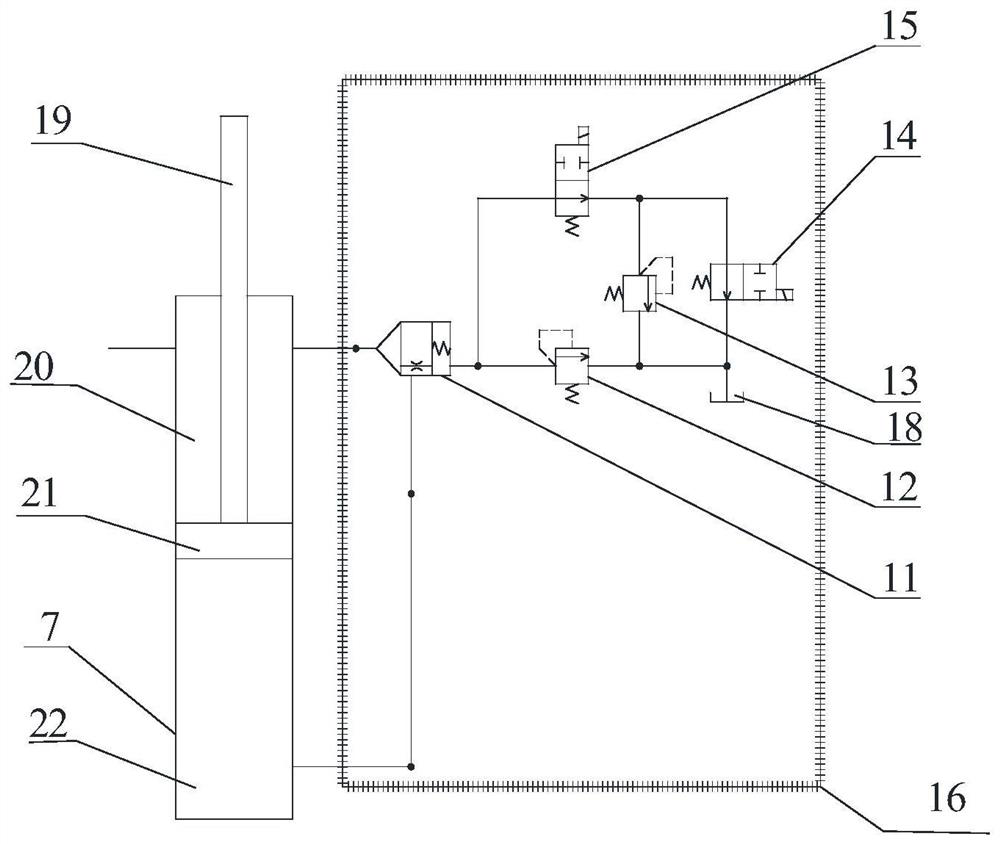

[0055] In this embodiment, only the method for determining the time when the rammer starts to touch the ground and the structure adopted are slightly different, and the others are the same as those in Embodiment 1, and the present embodiment will not repeat them for the similarities.

[0056] In this embodiment, the sensor is an acceleration sensor. The stroke sensor is not installed at the lifting cylinder, but the acceleration sensor is installed on the piston or piston rod or the movable pulley of the lifting cylinder, and the acceleration sensor is electrically connected with the control system.

[0057] Correspondingly, in this embodiment, only steps S1 and S2 are slightly different in the braking method of the hoisting mechanism of the dynamic compaction machine, and the working principle and working process of the other hydraulic control circuits including S1 and S2 are the same.

[0058] Among them, S1: the control system issues a command to lift the rammer. After the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com