Precision printing machine

A printer, precision technology, applied in the direction of printing device, printing, etc., can solve the problems of affecting the printing effect, reducing the service life of the equipment, and the wear of printing rollers and other devices, so as to ensure the transmission accuracy and transmission stability, improve the precision, and ensure The effect of precision control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

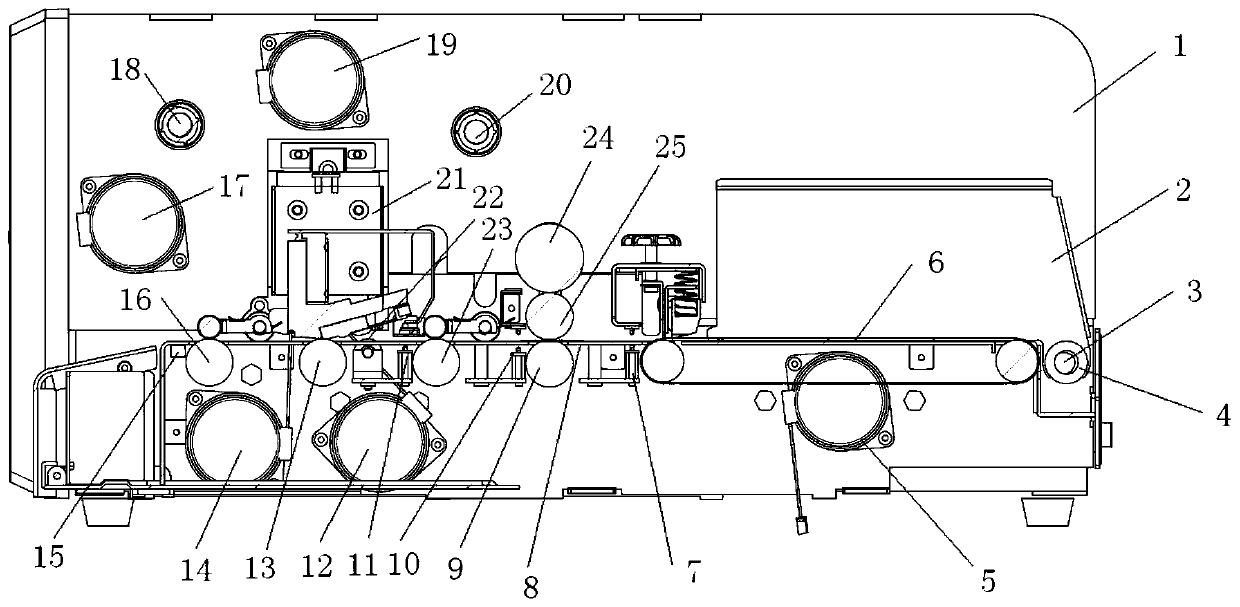

[0019] A precision printer comprising a casing 1, an annular suction card belt 6 installed in the casing, a paper feed passage 8, a pair of mutually matched dust removal rollers and a print head 21, the annular suction card belt is powered by a card suction motor 5 drive, a pair of dust removal rollers that cooperate with each other are located in front of the ring suction card belt, which includes the dust removal active roller 9 located below the paper feed passage and the dust removal passive roller 25 above the paper feed passage, and the front of the dust removal roller is installed. Card dust removal sensor 10, the front of card dust removal sensor is hinged with printing head, the printing roller 22 that is driven to rotate by printing motor 12 is installed below the printing head, is installed between the motor shaft of printing motor and the roller shaft of dust removal driving roller. The transmission gear (not shown) that meshes with each other, the control end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com