Novel swing type plane grinding device

A flat grinding and swinging technology, applied in grinding devices, grinding drive devices, grinding machine tools, etc., can solve the problems of inconsistent wear and low precision of grinding discs, and achieve high grinding precision and efficiency, accurate transmission, and convenient disassembly and assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

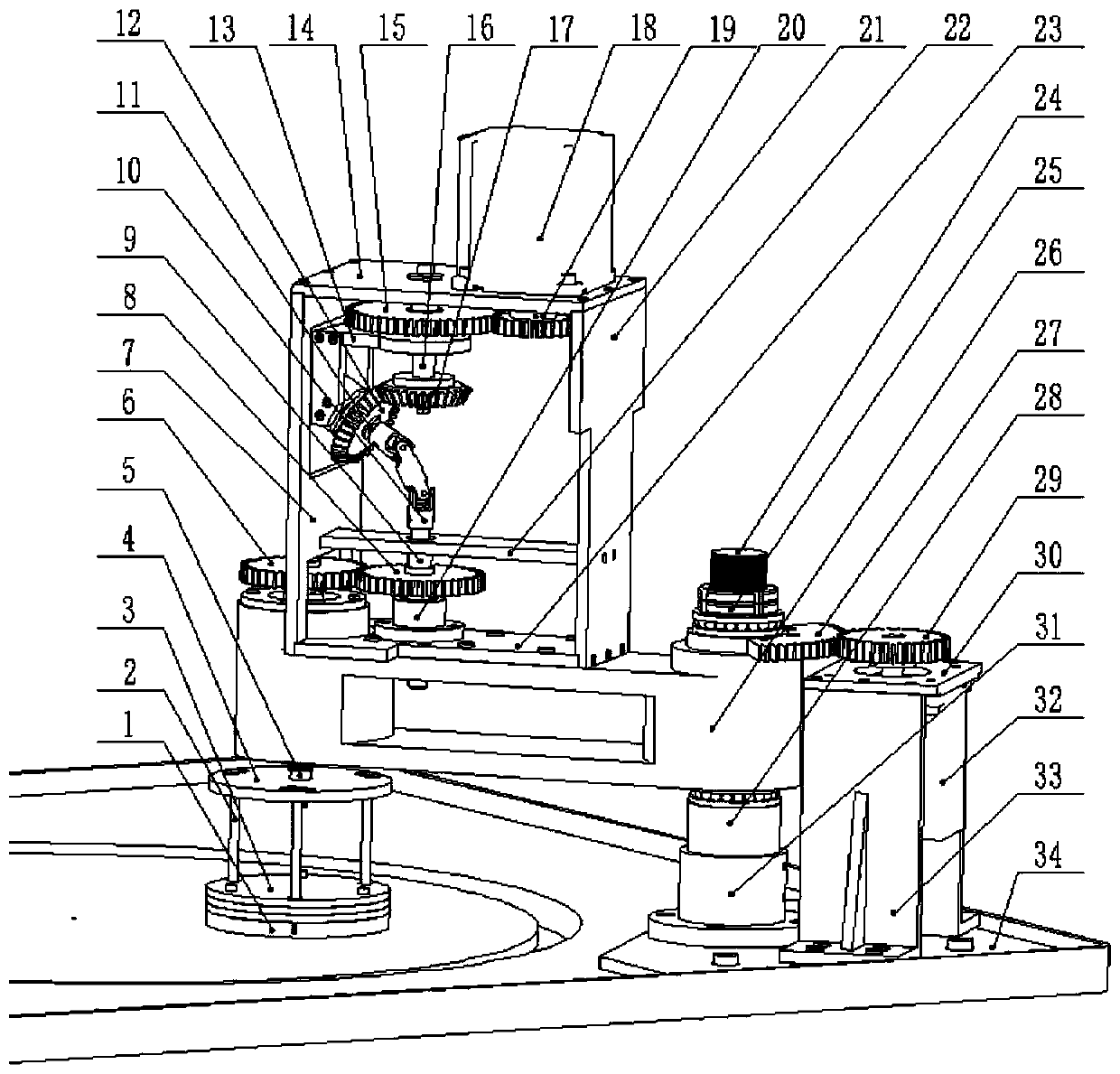

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] refer to figure 1 , a new type of swinging surface grinding device, including workpiece plate, counterweight plate, plunger, chuck, shaft V, cylindrical gear VI, open vertical plate, cylindrical gear V, shaft IV, universal joint, shaft III, cone Gear Ⅱ, planet carrier, motor plate Ⅱ, cylindrical gear Ⅳ, shaft Ⅱ, bevel gear Ⅰ, motor Ⅱ, cylindrical gear Ⅲ, flange Ⅱ, T-shaped vertical plate, fixed plate, box bottom plate, shaft Ⅰ, small round nut , Large rocker arm, cylindrical gear Ⅱ, bushing, cylindrical gear Ⅰ, motor plate Ⅰ, flange Ⅰ, motor Ⅰ, fixed vertical plate, grinding machine fixed plate.

[0023] The motor I32 is fixedly installed on the motor plate I30, and the motor shaft is directly connected with the cylindrical gear I29; the upper part of the fixed vertical plate 33 is fixedly connected with the motor plate I30 through screws, and the lower part is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com