Pipe opening device and hole opening method

A technology for pipes and pipe fittings, which is applied in the field of pipe opening devices and openings, can solve the problems of time-consuming, laborious, poor adjustability, and large deviation in changing punches, and achieves fast and accurate positioning adjustment, convenient replacement, and good positioning accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

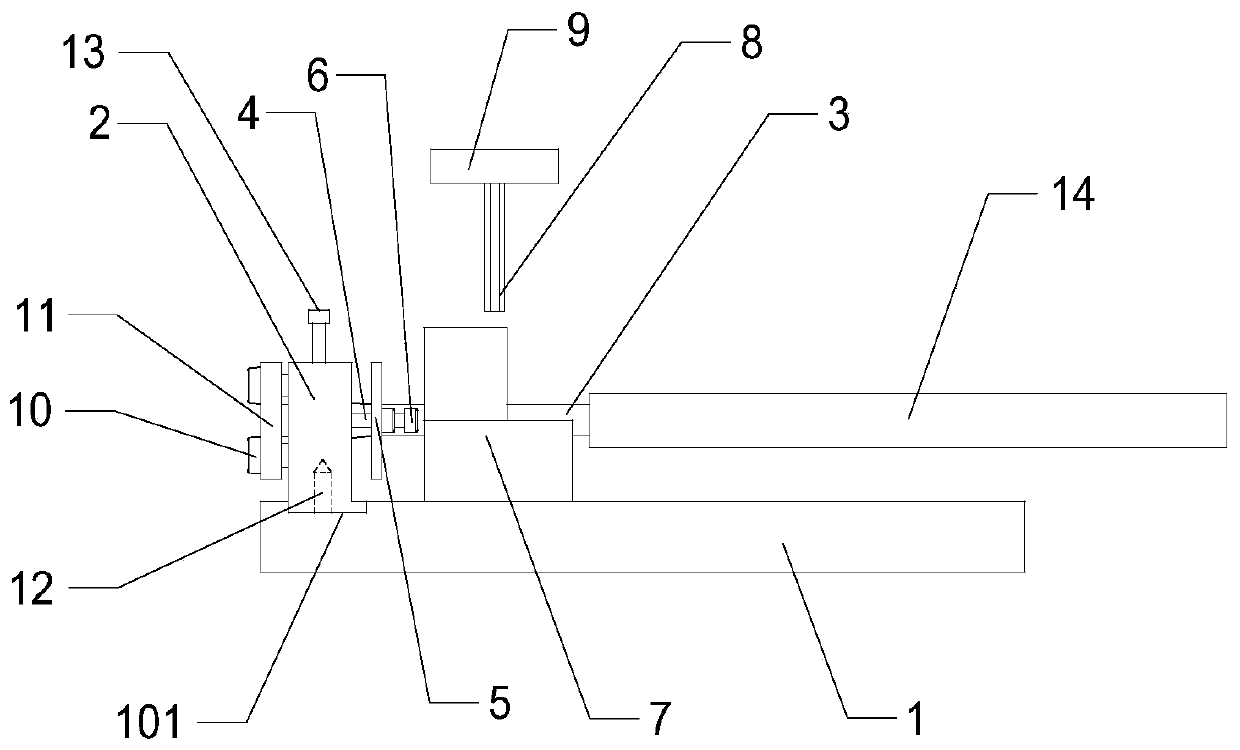

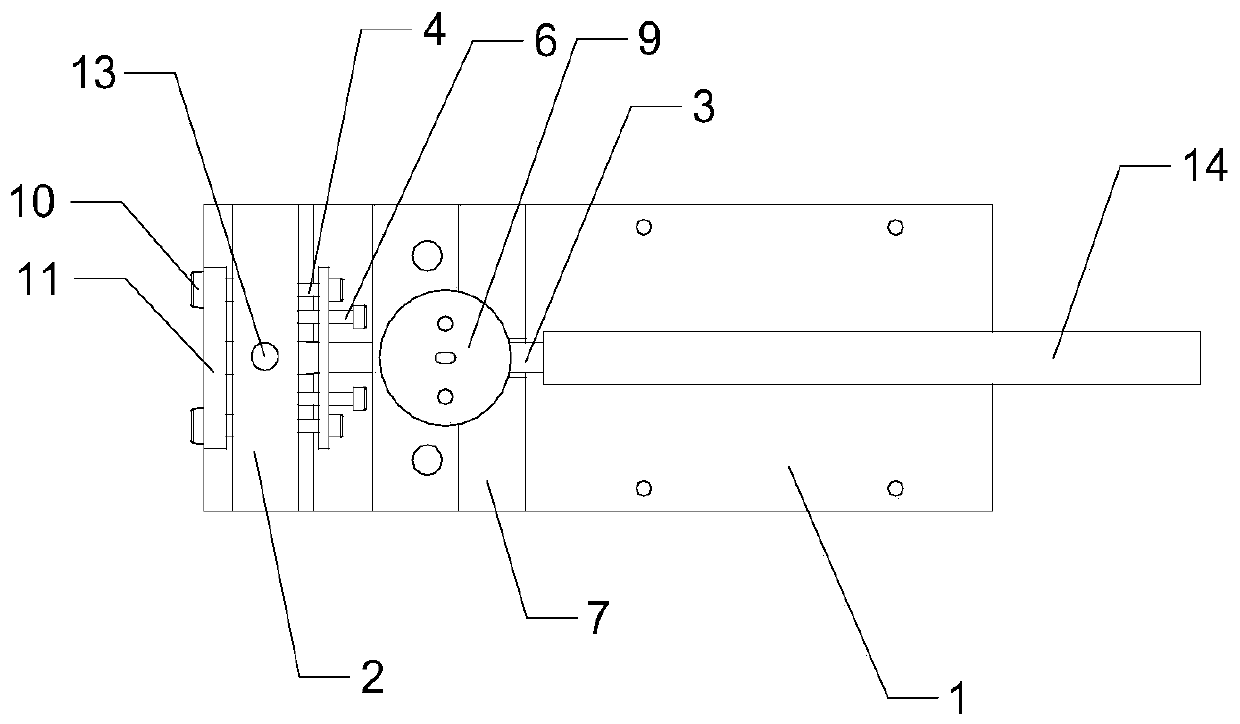

[0040] Such as Figure 1-5 As shown, the present invention is a pipe hole opening device, including a base plate 1, a positioning boss 2 and a punch 3 installed on a machine tool workbench, the base plate 1 is provided with a groove 101, and the positioning boss 2 The bottom of the bottom is adapted to the groove 101 and installed on the base plate 1, and the middle part of the positioning boss 2 is provided with a first through hole 201; the front side of the positioning boss 2 is fixed with a positioning adjustment plate 5 by a bolt A4, so The positioning adjustment plate 5 is provided with a second through hole 501, and the positioning adjustment plate 5 is also threaded with an adjustment bolt 6; it also includes a positioning pad 7 fixed on the bottom plate 1, and the positioning pad 7 is arranged on the positioning adjustment plate. 5, the positioning pad 7 is provided with a third through hole 701, the punch 3 runs through the first through hole 201, the second through ...

Embodiment 2

[0043] This embodiment is a further description of the present invention.

[0044] Such as Figure 1-5 As shown, this embodiment is based on Embodiment 1. In a preferred embodiment of the present invention, the punch 3 includes a first circular platform 303 and a cylinder A302 and a cylinder B304 connected to both ends of the first circular platform 303, and the cylinder The diameter of A302 is greater than the diameter of the cylinder B304, the cylinder A302 and the side of the first round platform 303 are also provided with a cutting surface, the punching hole 301 is set on the cylinder B304, the cylinder A302 is matched with the first through hole 201 and runs through The first through hole 201 of the positioning boss 2 is positioned.

[0045] With the above-mentioned structure, the first round table 303 is set between the cylinder A302 and the cylinder B304, and the original stress points of the punch 3 are distributed to each stress area of the punch 3, so that the fix...

Embodiment 3

[0050] This embodiment is a further description of the present invention.

[0051] Such as Figure 4 As shown, this embodiment is based on the above, in a preferred embodiment of the present invention, the positioning pad 7 includes a lower pad 703 and an upper pad 704, and the third through hole 701 includes openings in the lower pad 703 The arc-shaped through groove A7011 on the top and the arc-shaped through groove B7012 on the pad 704. With the above structure, the upper cushion block 704 and the lower cushion block 703 are fixed together by bolts, and the through slot A7011 is matched with the through slot B7012 to form the third through hole 701 .

[0052] In a preferred embodiment of the present invention, the arc lengths of the through groove A7011 and the through groove B7012 are equal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com