Winchester hard-disk drive disk cleaning tool and cleaning method

A hard disk platter and cleaning method technology, applied in the direction of using gas flow cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as easy scratches, bumps, etc., to ensure fixed stability and improve recovery The effect of replacement success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

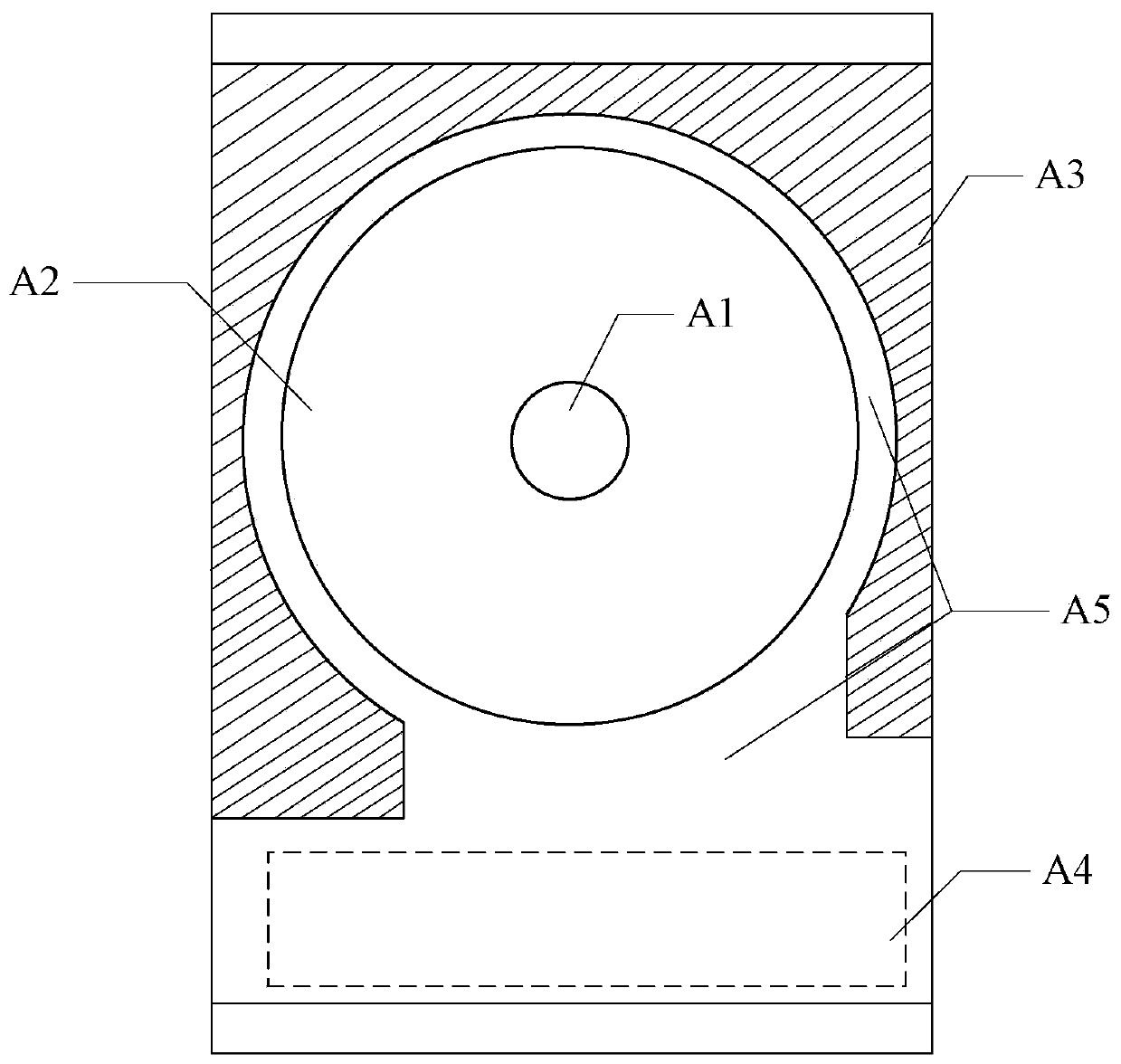

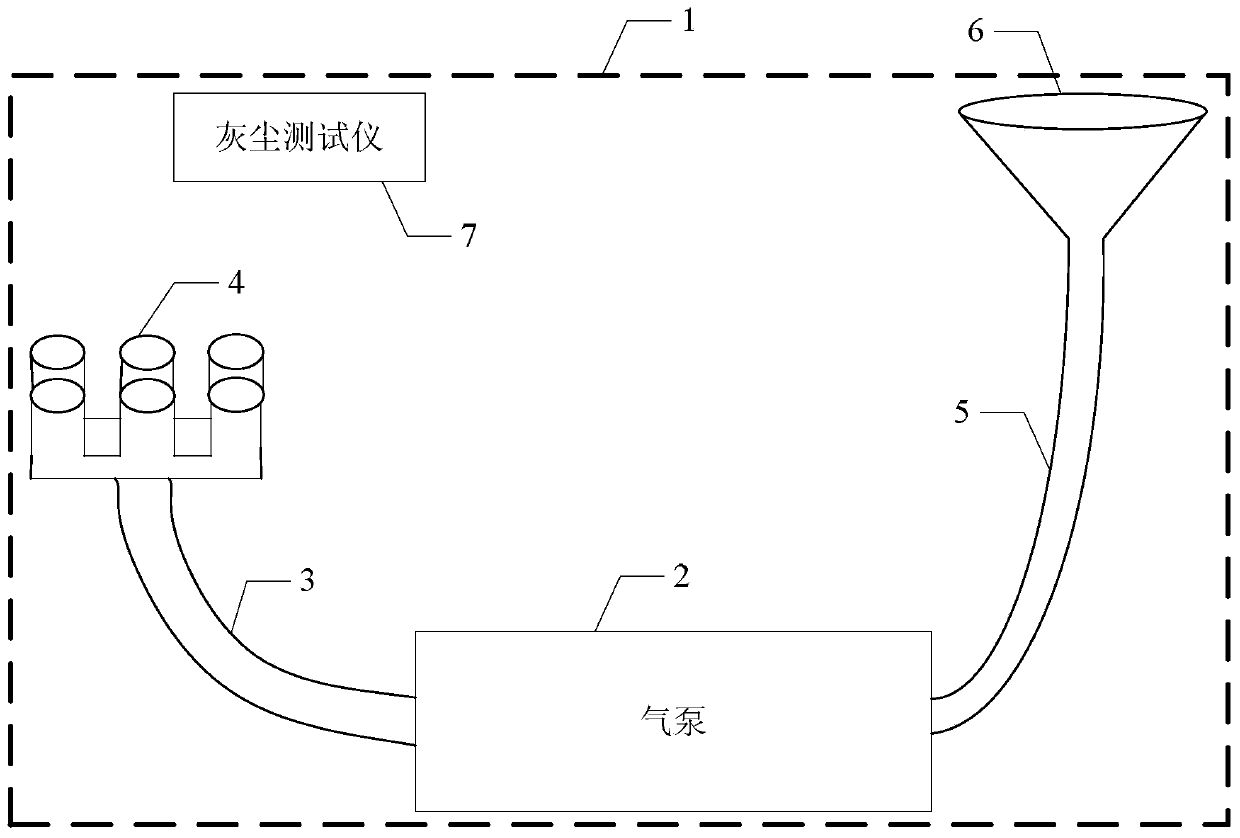

[0036] Specific implementation mode one: combine Figure 3 to Figure 6 Describe this embodiment, a kind of cleaning tool of Winchester hard disk described in this embodiment, a kind of cleaning tool of Winchester hard disk, it is characterized in that, this disk cleaning tool includes air shower 1. Air pump 2, air outlet pipe 3, air outlet head 4, air inlet pipe 5 and air inlet head 6;

[0037] One end of the air inlet pipe 5 communicates with the air inlet of the air pump 2, and the other end of the air inlet pipe 5 communicates with the air inlet head 6;

[0038] One end of the air outlet pipe 3 is connected to the air outlet of the air pump 2, and the other end of the air outlet pipe 3 is connected to the air outlet head 4; the air pump 2 requires 10-15 liters of air intake per minute, and the air volume is adjustable;

[0039] The air outlet head 4 and the air inlet head 6 are respectively fixed in the air shower room 1;

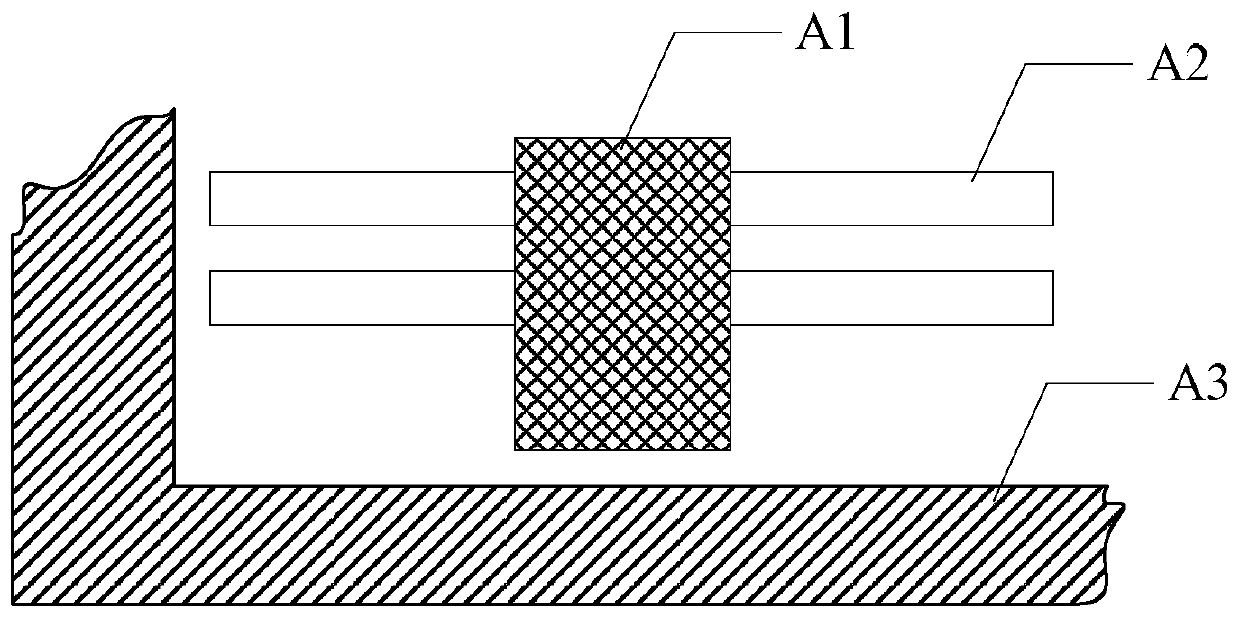

[0040] The air outlet head 4 includes an array t...

specific Embodiment approach 2

[0049] Embodiment 2: This embodiment further defines the cleaning tool for a Winchester hard disk described in Embodiment 1. In this embodiment, the disk cleaning tool also includes a dust tester 7;

[0050] The dust tester 7 is set in the air shower room 1 .

[0051] In this embodiment, the cleanliness of the air shower 1 is tested by the dust tester 7, and the Winchester hard disk can be cleaned only after the cleanliness in the air shower 1 reaches 100 grades.

specific Embodiment approach 3

[0052] Specific implementation mode three: combination Figure 7Describe this embodiment, this embodiment is to further limit the cleaning tool of a kind of Winchester hard disk described in specific embodiment one, in this embodiment, this disk cleaning tool also includes bracket 8 and N sucker 9;

[0053] The center of the bracket 8 is provided with a fixing hole, and the horn-type air outlet head or the horn-type air inlet head is stuck in the fixing hole, and the bracket 8 is used to fix the horn-type air outlet head or the horn-type air inlet head;

[0054] The N suction cups 9 are respectively arranged at the bottom of the bracket 8; the suction cups 9 are used to be adsorbed on the stainless steel plate on the inner wall of the air shower room 1, or a clean bench is set in the air shower room 1, and the suction cups 9 are used to be adsorbed on the clean bench On, complete the fixation to bracket 8;

[0055] The N is a positive integer greater than or equal to 3.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com