Temperature control device of vacuum stirrer

A technology of temperature control device and vacuum mixer, applied in mixer accessories, mixer, transportation and packaging, etc., can solve the problems of inability to guarantee the temperature consistency of the mixer, the stability of the mixing process, the inability to realize the temperature rise of the mixer, and the discharge of cooling water, etc. Improve product quality and work efficiency, ensure stability, and reduce the effect of vibration and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to facilitate understanding of the present invention, the present invention will be fully described below with reference to the accompanying drawings. Preferred embodiments of the invention are shown in the accompanying drawings. However, the invention may be embodied in many different forms, and this is not intended to limit the scope of the invention.

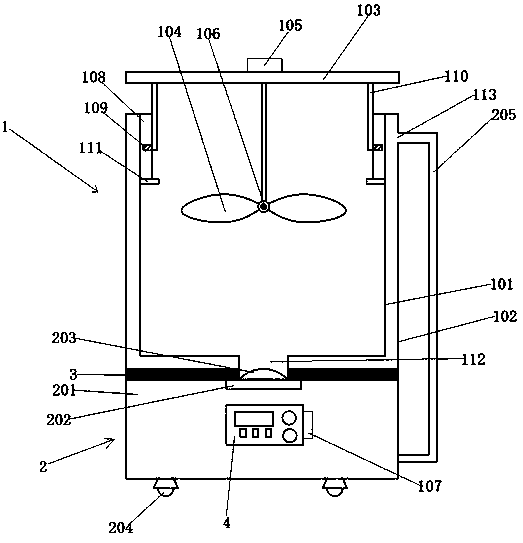

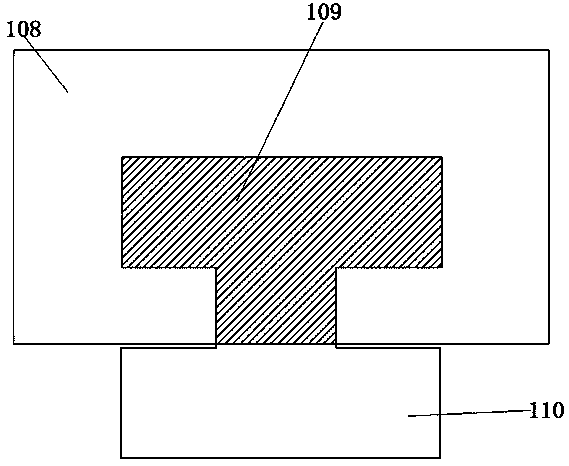

[0022] Example Figure 1-2 As shown, a temperature control device for a vacuum mixer 1 includes a vacuum mixer 1, a constant temperature oil bath 2, a barrier layer 3, and a control mechanism 4; the vacuum mixer 1 includes: a mixer inner shell 101, a mixer shell 102, a top Cover 103, stirring kettle 104, mixer driving mechanism 105, temperature sensor 106, potentiometer 107, guide rail 108, slider 109, guide rail rod 108, end plate 111, liquid inlet 112, liquid outlet 113; the constant temperature oil bath The pot 2 includes: an oil bath pot body 201, a flow regulating valve 202, an oil pump 203, a roller 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com