A loudspeaker cone and preparation method thereof, loudspeaker

A loudspeaker and sound cone technology, applied in sensors, non-planar diaphragms/paper cones, electrical components, etc., can solve the problems of high frequency expansion limitations, small elastic modulus, large internal damping, etc. Young's modulus, effect of good Young's modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

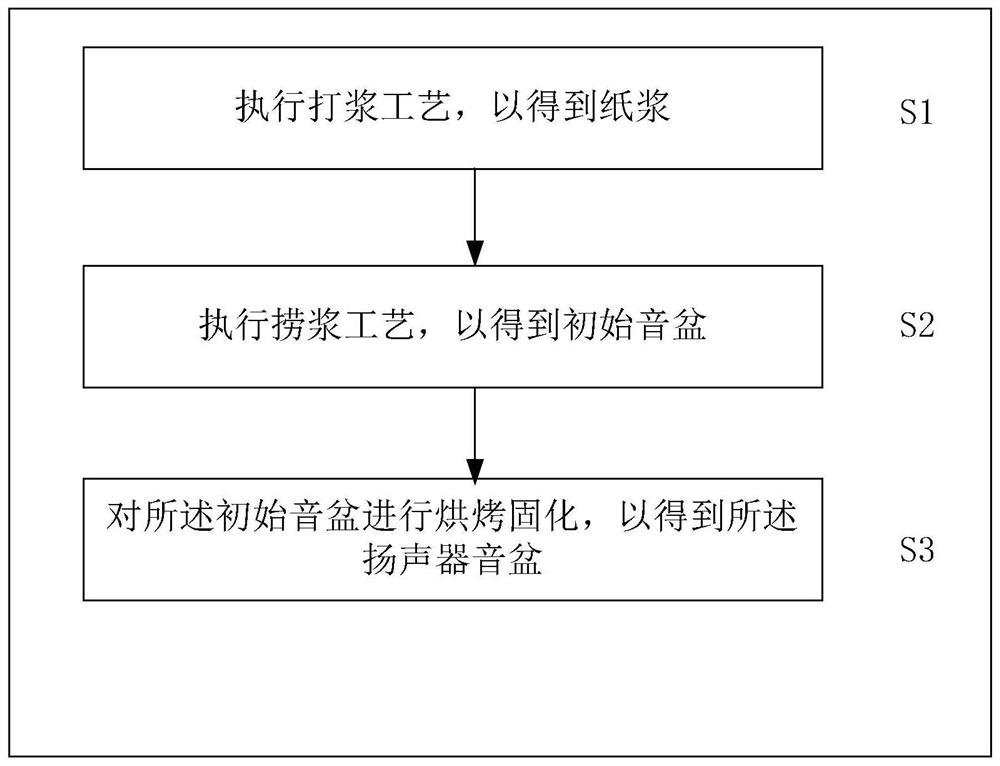

[0043] In order to solve the above-mentioned technical problems existing at present, the present invention provides a kind of preparation method of loudspeaker cone, this method comprises:

[0044] performing a beating process to obtain pulp;

[0045] Execute the pulping process to obtain the initial sound cone;

[0046] Baking and curing the initial cone to obtain the speaker cone;

[0047] Wherein, the rigid regulating substance is added in the process of preparing the loudspeaker cone.

[0048]The loudspeaker cone of the present invention has a good Young's modulus and a lower density after the rigidity regulating substance is added, and the density of the rigidity regulating substance mixed into the pulp can be adjusted according to performance requirements to achieve a higher Young's modulus volume, for lighter density purposes. After the rigidity adjustment substance is added, the Young's modulus of the pulp is enhanced, and the existing high internal resistance of th...

Embodiment 1

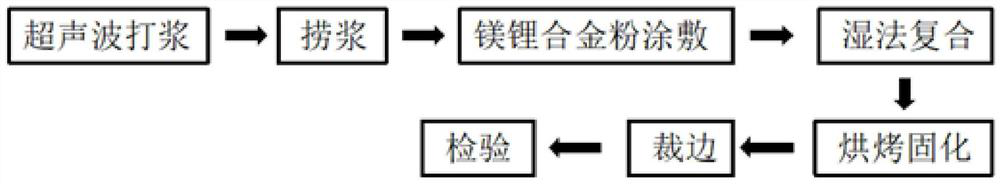

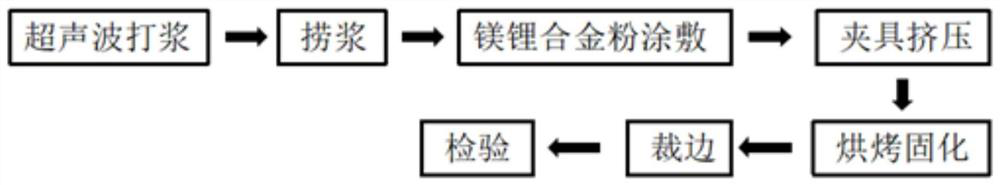

[0050] Refer below Figure 1 to Figure 5 The preparation method of the loudspeaker cone of the present invention is explained and illustrated, wherein, figure 1 A schematic flow diagram showing a method for preparing a loudspeaker cone in an embodiment of the present invention; figure 2 A schematic block diagram showing a method for preparing a loudspeaker cone in an embodiment of the present invention; image 3 A schematic block diagram showing a method for preparing a loudspeaker cone in another embodiment of the present invention; Figure 4 A schematic block diagram showing a method for preparing a loudspeaker cone in yet another embodiment of the present invention; Figure 5 A schematic block diagram showing a method for preparing a loudspeaker cone in another embodiment of the present invention.

[0051] In one embodiment of the present invention, step S1 is first performed: performing a beating process to obtain pulp.

[0052] In this step, some specific properties ...

Embodiment 2

[0095] The present invention also provides a loudspeaker cone, which can be prepared by the method in Embodiment 1.

[0096] The loudspeaker cone includes: a sound cone main body, which is used to emit sound through the vibration of the sound basin main body, and the sound basin main body contains a rigid adjustment material to improve the rigidity of the loudspeaker cone.

[0097] Among them, the selection of the rigid adjustment material is not arbitrary, and the rigid adjustment material needs to have greater rigidity than the paper cone, and has a relatively small density, so that the loudspeaker cone with the rigid adjustment material can achieve a higher Young's modulus, for lighter density purposes. To effectively solve the problem of insufficient Young's modulus of the paper cone speaker, the sound quality of the speaker is improved, and it sounds more self-heating and clear; at the same time, the breadth of high frequency is widened, and the sound performance is more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com