Novel HCN laser cavity length adjusting mechanism

An adjustment mechanism and laser technology, applied in the optical field, can solve the problems of complex installation, many device parts, adjustment accuracy can not meet the difference frequency adjustment of HCN dual lasers, etc., and achieve the effect of small size and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

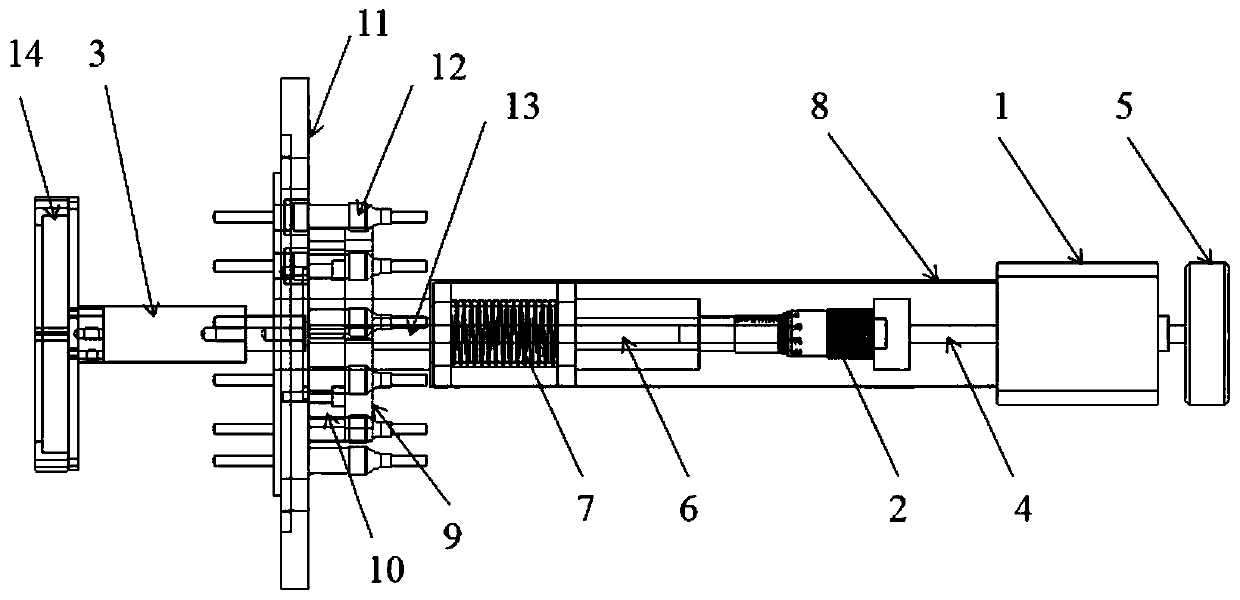

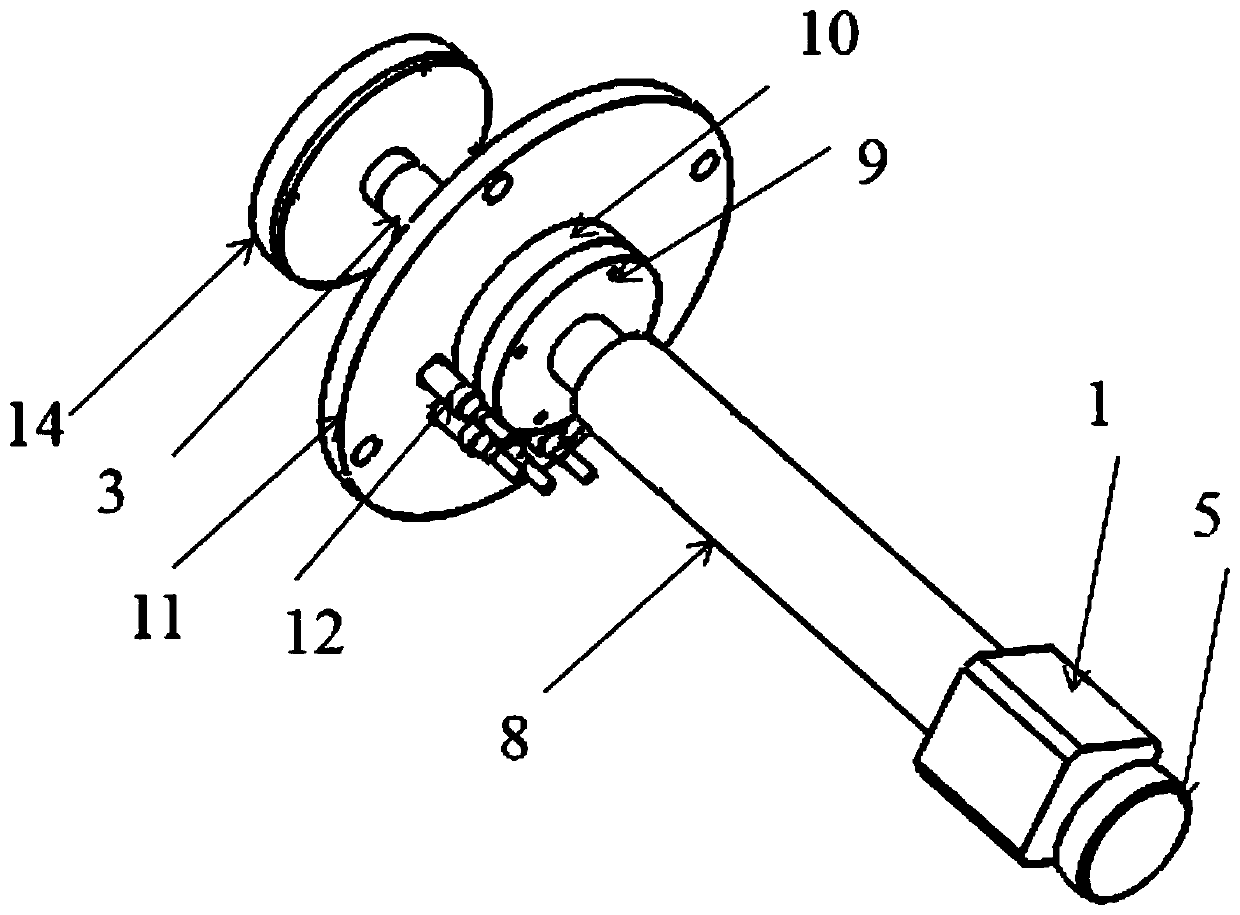

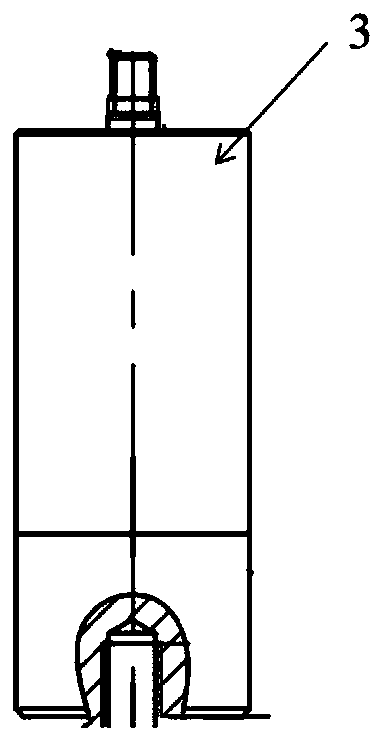

[0028] Such as figure 1 , 2 , 3, and 4, a new type of HCN laser cavity length adjustment mechanism includes a stepper motor 1, a high-precision differential head 2 and a piezoelectric ceramic 3, and the front end of the stepper motor 1 connects the screw rod 4 with the high The precision differential head 2 is connected, the rear end of the stepping motor 1 is connected to the adjustment knob 5, the connecting part 6 is sealed and welded on the bellows spring 7, and the bellows spring 7 is welded on the stainless steel shell 8, so The front end of the stainless steel shell is connected to a stainless steel vacuum flange 9, and the stainless steel vacuum flange 9 is connected to a ceramic flange 10 of the same size to ensure insulation, and the ceramic flange 10 is connected to the laser cathode sealing flange 11 , the laser cathode sealing flange 11 is processed with 6 vacuum lead posts 12 to lead out the power line and signal line of the piezoelectric ceramic 3, and the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com