Battery wrapping machine and battery wrapping assembling machine comprising battery wrapping machine

A technology of battery packs and triggers, which is applied in the direction of battery assembly, secondary battery manufacturing, sustainable manufacturing/processing, etc. It can solve the problems of easy generation of heavy metal dust, waste of manpower and material resources, and low production efficiency, and achieve the efficiency of packaging boards High efficiency, high efficiency and high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

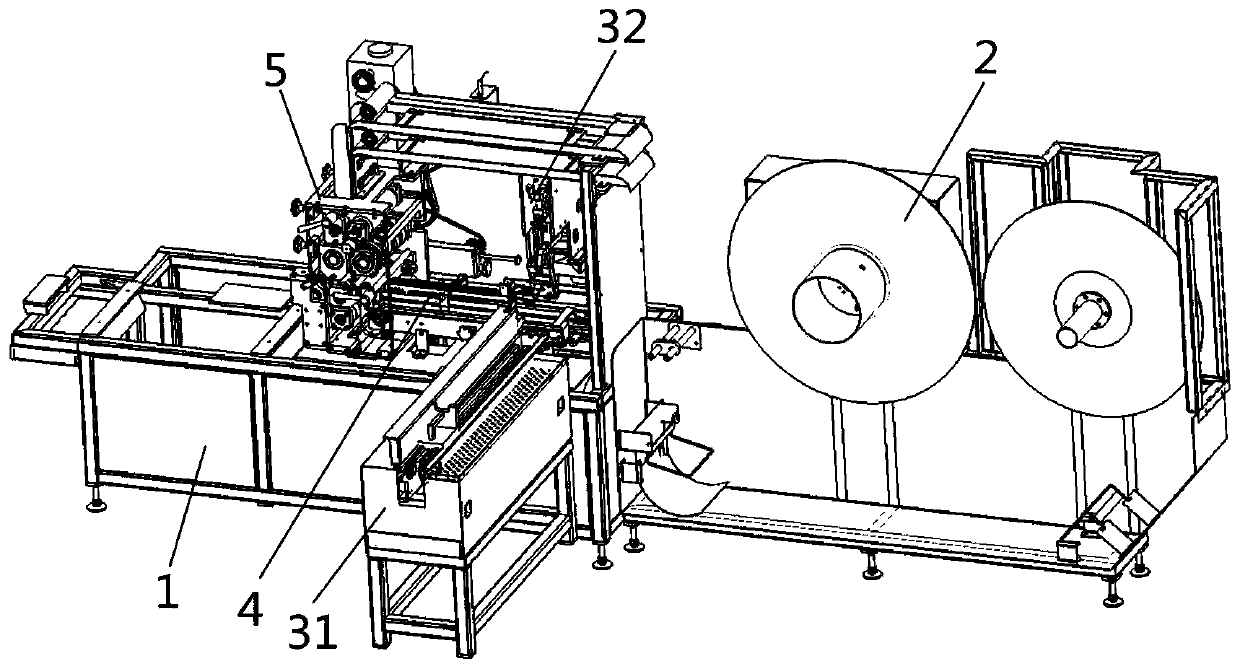

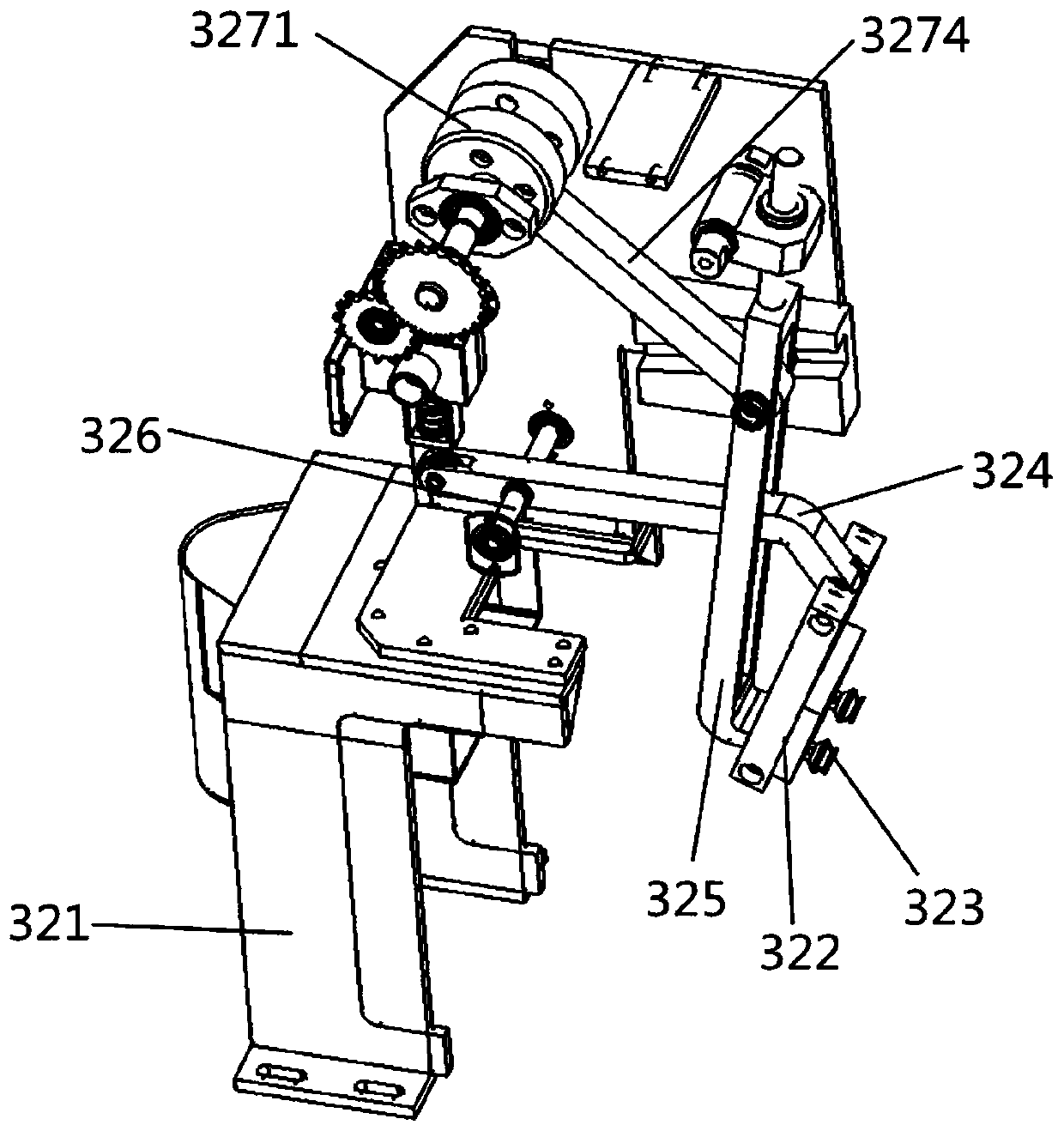

[0038] Such as figure 1 As shown, the present invention provides a battery pack plate assembly machine, including a frame 1 and a paper feeding device 2 arranged on the frame 1, a feeding device, a plate feeding conveying device 4, and a separator paper cutting device 5 and a pressing mechanism 6, the separator paper cutting device 5 has a paper feed channel 56 for conveying the separator paper from top to bottom, the width direction of the paper feed channel 56 is set along the front and rear directions, and the paper feed channel The feed end of 56 extends upwards to the upper end of the separator paper cutting and loading paper 5, the discharge end of the paper supply device 2 communicates with the feed end of the separator paper cutting device 5, and the paper supply device 2. Send the separator paper into the separator paper cutting device 5, and the separator paper is cut to a set length in the paper feeding channel 56. A pole plate passage 57 for conveying the pole pla...

Embodiment 2

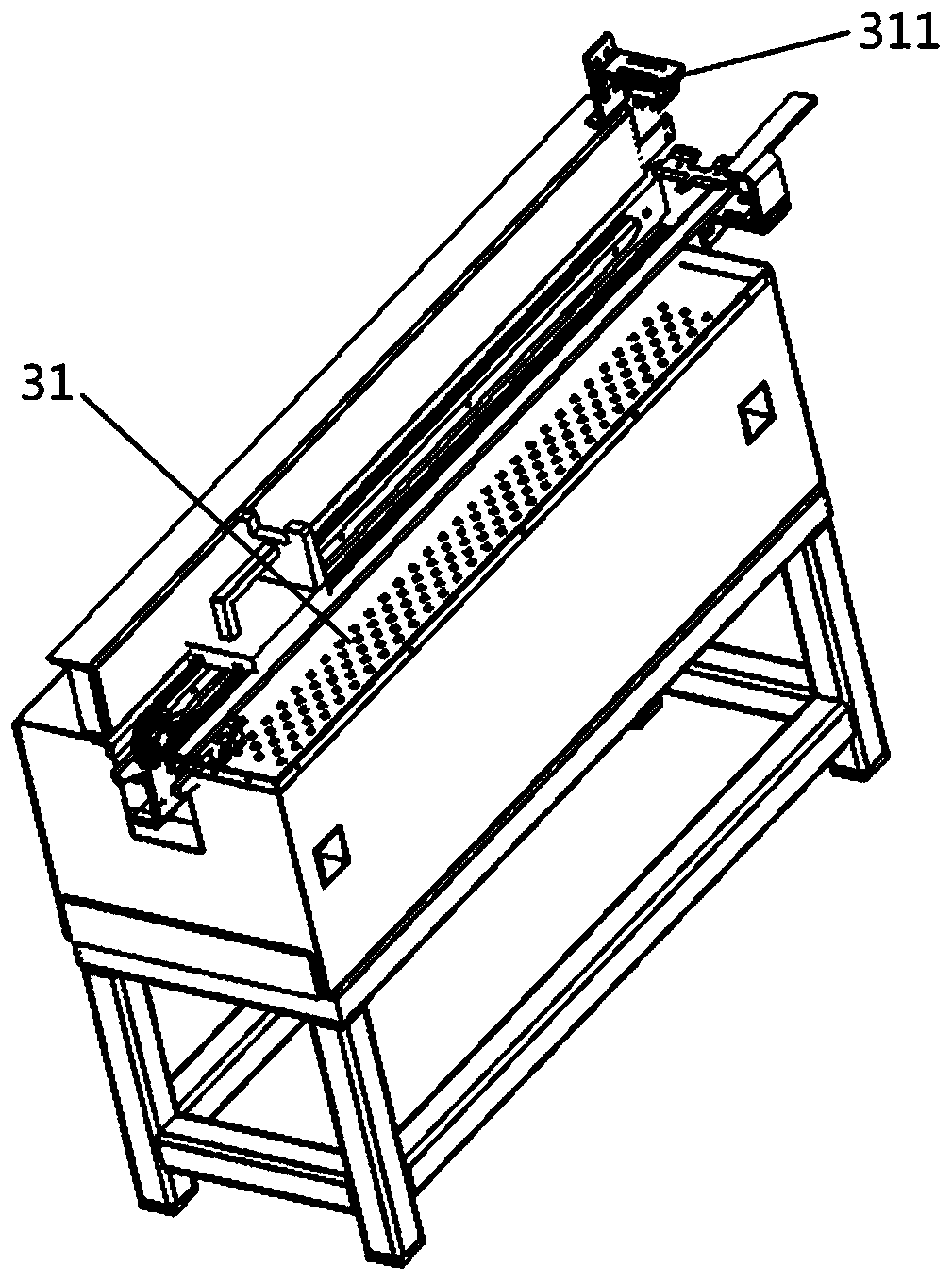

[0053] Such as Figure 8-9 As shown, this embodiment also provides a battery pack board assembly machine, including the above battery pack board machine, and also includes a board delivery device 7 and a side board delivery device 8, and the board delivery device 7 is arranged on the At the outlet end of the plate channel 57, the side plate conveying device 8 is vertically arranged on the discharge end of the plate discharging device 7, and the plate discharging device 7 and the side plate conveying device 7 Next to the plate conveying device 8, a feeding mechanism 31 is respectively provided to send the polar plate and the side plate opposite to the polarity of the polar plate on the feeding plate conveying device 4 to the outgoing plate conveying device 7 and the side plate conveying device 8 respectively. Above, after the plate is wrapped, it is sent to the plate delivery device 7, and the corresponding feeding device on the plate delivery device 7 stacks the polar plate wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com