Luminous backlight source of single-ring sag type curved surface cathode three-back-arc-layer gating structure

A curved cathode and backlight technology, applied in the manufacture of cold cathode tubes, solid cathodes, and cold cathodes, can solve the problems of carbon nanotube cathodes losing control functions, losing essential functions, and not being able to emit electrons from carbon nanotube cathodes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to this embodiment.

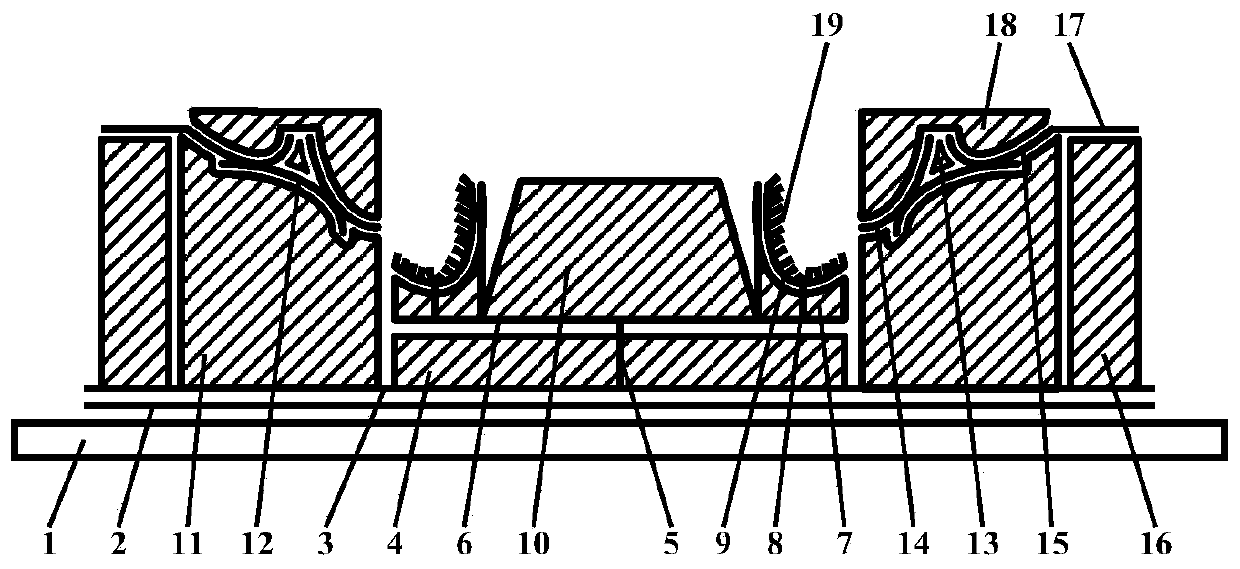

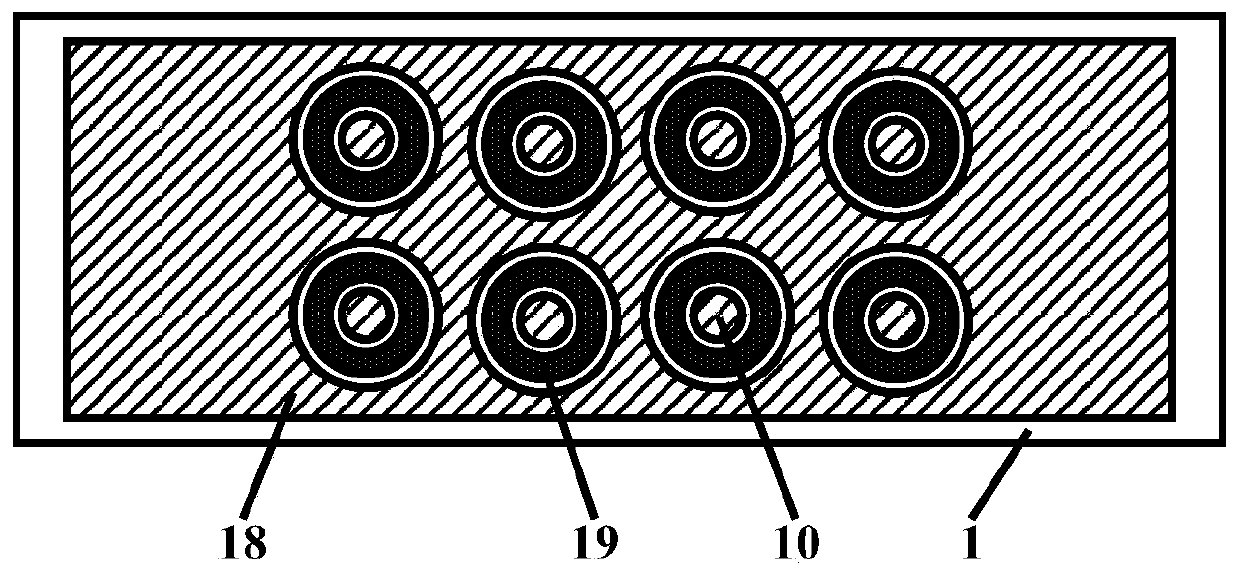

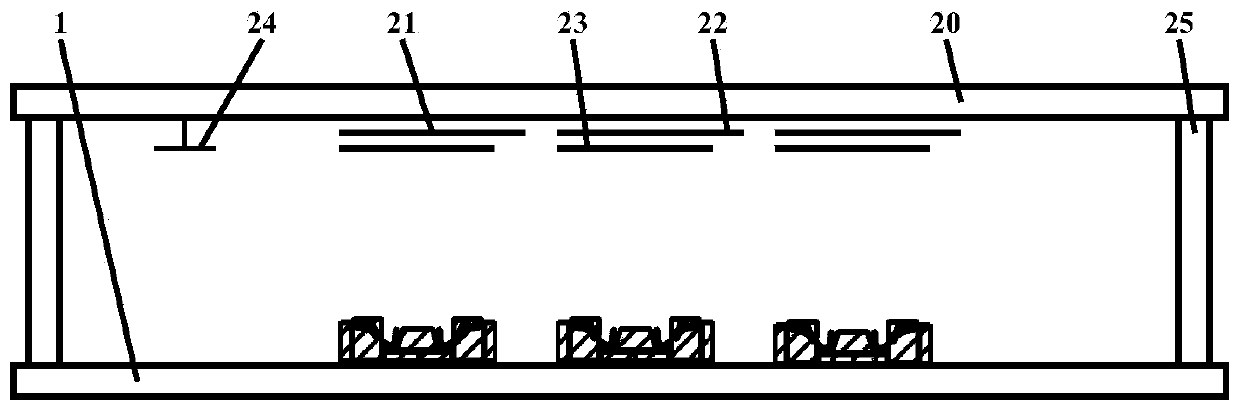

[0050] The light-emitting backlight of the single-ring groove-shaped curved surface cathode with three back-arc layer gating structures in this embodiment is as follows: figure 1 , figure 2 with image 3 As shown, it includes a vacuum enclosure and a getter 24 accessory components located in the vacuum enclosure; the vacuum enclosure is composed of a front transparent hard glass plate 20, a rear transparent hard glass plate 1 and a glass narrow frame strip 25; the front transparent The hard glass plate has an anode bottom film conductive layer 21, an anode bend connecting silver layer 22 and a thin light-emitting layer 23, the anode bottom film conduction layer is connected to the anode bend connection silver layer, and the thin light-emitting layer It is made on the conductive layer of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com