Refrigeration heat exchange pipeline assembly with defrosting function and refrigerant conveying pipe

A technology of heat exchange tubes and pipelines, applied in the field of refrigeration and defrosting, which can solve the problems of not being able to make full use of the heat energy of the defrosting heating wire to quickly defrost, frost on the surface of the pipeline, and affect the vaporization effect, so as to ensure normal and efficient operation, Extend the defrosting cycle and improve the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

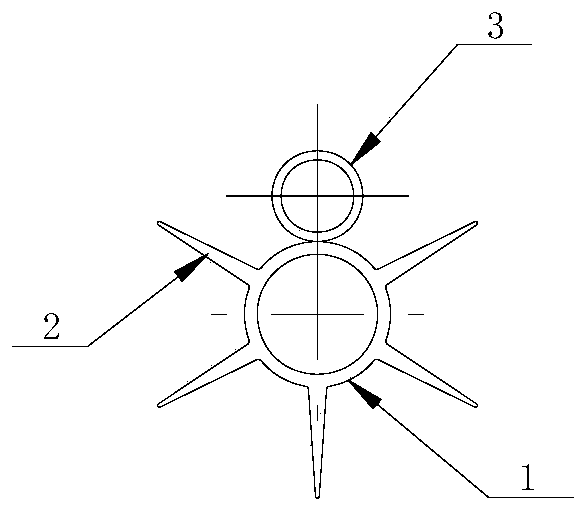

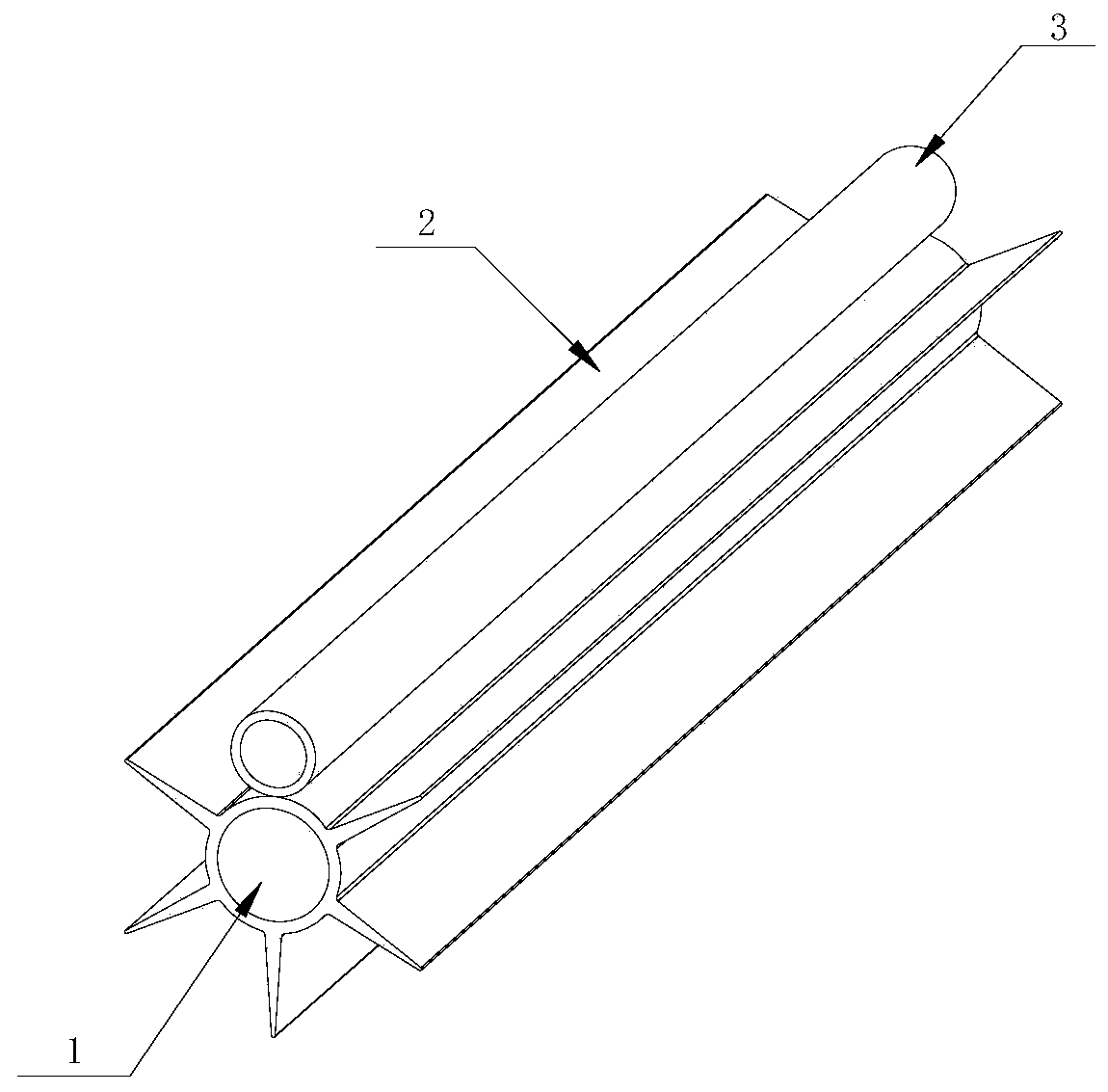

[0044] Example 1, see figure 1 and figure 2 , a refrigeration heat exchange pipeline assembly with defrosting, including a pipeline 1 with an inlet and an outlet, the outer circumference of the pipeline is integrally provided with several continuous heat exchange fins 2, and also includes a pipeline fixed on the pipeline The electric heating tube 3; the length direction of the heat exchange fins is consistent with the axial direction of the pipeline.

[0045] In this embodiment, the heat exchange fins and the pipeline are directly formed by pulling and forming in actual production. Compared with the existing cooling fins installed on the pipeline, the heat dissipation effect of this structure is better than that of the assembled structure, and it is different from the assembled structure. Compared with the omitted fin assembly process; in order to improve the connection strength between the heat exchange fin and the pipeline, the thickness of the root of the fin is greater t...

Embodiment 2

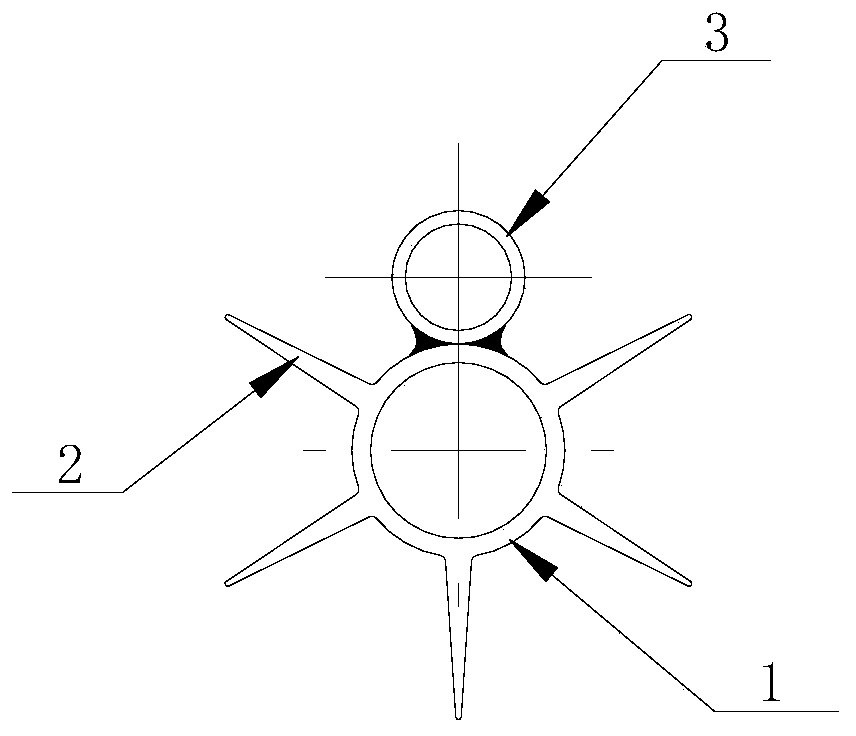

[0046] Example 2, see image 3 , in this embodiment, the electric heating tube is glued between two adjacent heat exchange fins, and is pasted on the outer wall of the pipeline by an adhesive, and the adhesive is made of heat-conducting glue on the market. Bonding, after bonding, the heat transfer will not be affected; the electric heating tube is bonded to the root of the evaporator tube Louis frosting and directly contacts for heat exchange. After the defrosting function is activated, the temperature at this position rises rapidly, reducing its The probability of secondary freezing occurs when the root temperature is low. The fixed method of adhesive is adopted, the installation speed is fast, and it is easy to adjust. It is easy to adjust the position of the electric heating tube in the early stage of curing. Once the electric heating tube is cured, the electric heating tube is relatively stable, and also reduces the production cost.

Embodiment 3

[0047] Example 3, see Figure 4 , the electric heating tube is glued between two adjacent heat exchanging fins, and pasted on the side of the heat exchanging fins by an adhesive.

[0048] The electric heating tube is bonded on the side of the heat exchange fin and the roots that are prone to frost are directly contacted for heat exchange. After the defrosting function is activated, the temperature at this position rises rapidly, and the heat is quickly transferred to the upper part of the pipeline, reducing its cause Probability of secondary icing due to low root and sidewall temperatures. The fixed method of adhesive is adopted, the installation speed is fast, and it is easy to adjust. It is easy to adjust the position of the electric heating tube in the early stage of curing. Once the electric heating tube is cured, the electric heating tube is relatively stable, and also reduces the production cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com