An anti-water hammer stop valve

A shut-off valve and water hammer technology, applied in the field of shut-off valves, can solve problems such as complex structure, many parts, damage to valve pipelines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

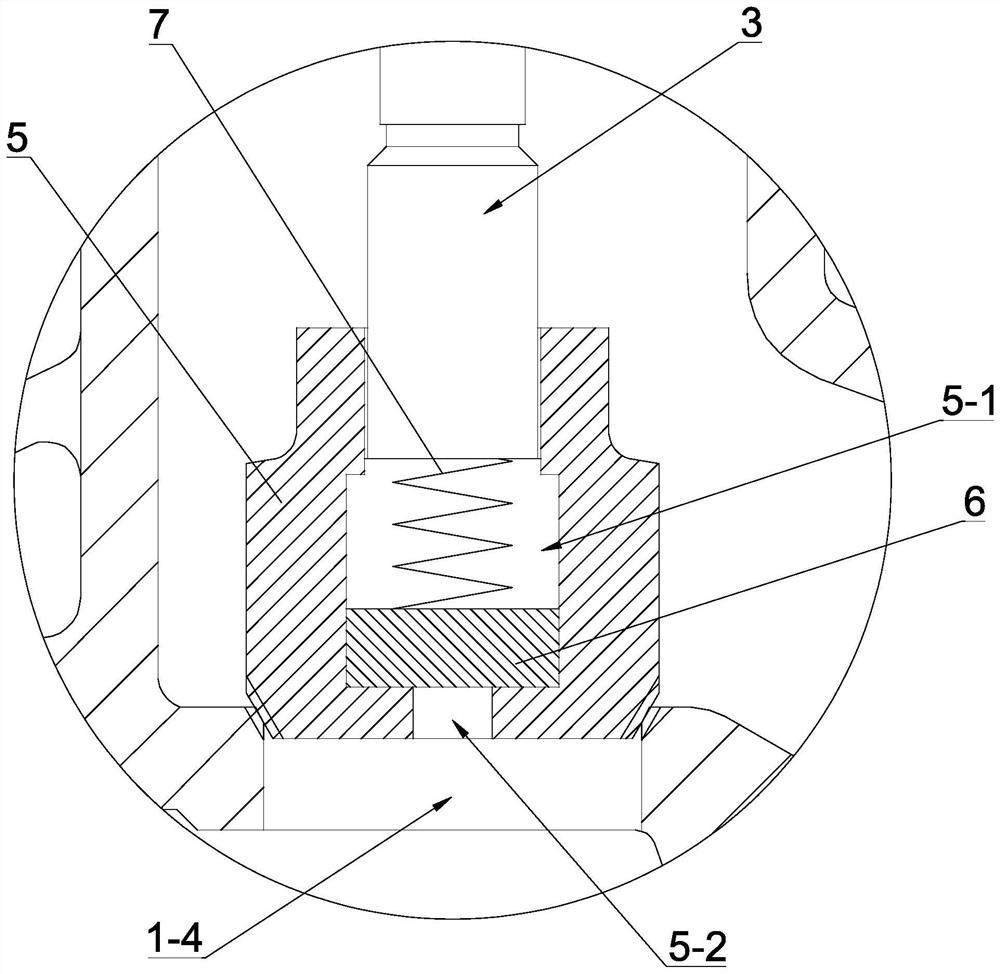

[0036] see Figure 1-Figure 2 , an anti-water hammer stop valve, comprising a valve body 1, the two ends of the valve body 1 are respectively provided with a water inlet 1-1 and a water outlet 1-2, and the water inlet 1-1 and the water outlet 1- 2 communicate through the inner cavity 1-3 of the valve body, and a communication port for connecting the water inlet 1-1 with the inner cavity 1-3 of the valve body is provided between the water inlet 1-1 and the inner cavity 1-3 of the valve body 1-4, the upper end of the valve body 1 is provided with a valve cover 2, the valve cover 2 is provided with a valve stem 3, the upper end of the valve stem 3 is connected with the hand wheel 4, and the lower end passes through the valve cover 2 and extends To the inner cavity 1-3 of the valve body, the lower end of the valve stem 3 is provided with a valve disc 5 fixedly connected with the valve stem 3 and used to close and open the communication port 1-4. It is characterized in that the val...

Embodiment 2

[0053] see image 3 , in this embodiment, the anti-water hammer sliding member 6 is arranged in the sliding hole 5-1 and is slidably fitted with the sliding hole 5-1, and the compression spring 7 is arranged in the sliding hole 5-1 1 and located between the anti-water hammer sliding piece 6 and the valve stem 3, one end of the compression spring 7 acts on the bottom of the valve stem 3, and the other end acts on the bottom of the anti-water hammer sliding piece 6 top. The design of the above structure is simple. When the valve is opened or closed, the water hammer generated when the valve is closed or opened can be buffered by the action of the anti-water hammer sliding part 6 and the compression spring 7, effectively reducing the water pressure of the valve and the pipeline. , Play the role of protecting valves and pipelines.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com