Equipment suitable for curing and heat preservation

A technology of equipment and thermal insulation layer, applied in the field of textile machinery, can solve the problems of failing to meet the reaction temperature and humidity requirements of the cross-linking agent, unable to produce high-quality cross-linked Lyocell fibers, etc., to improve market responsiveness, The effect of shortening development and production cycles and preventing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with example (accompanying drawing):

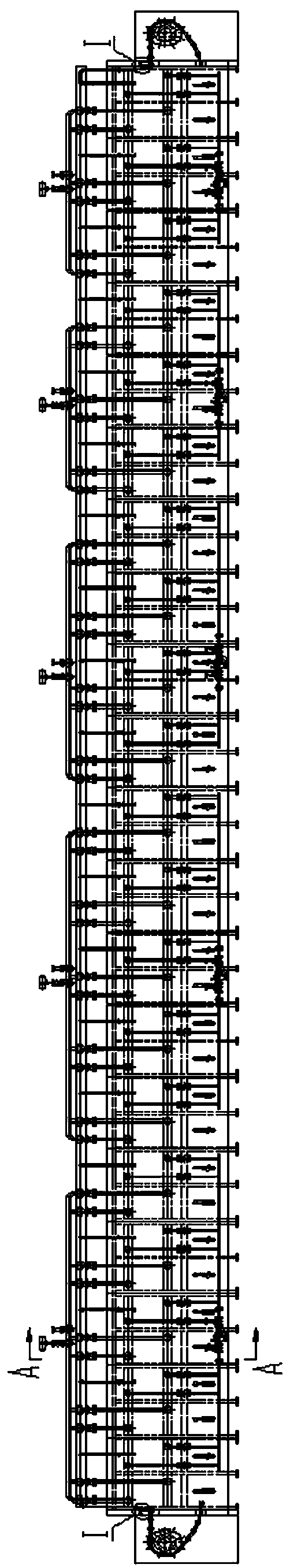

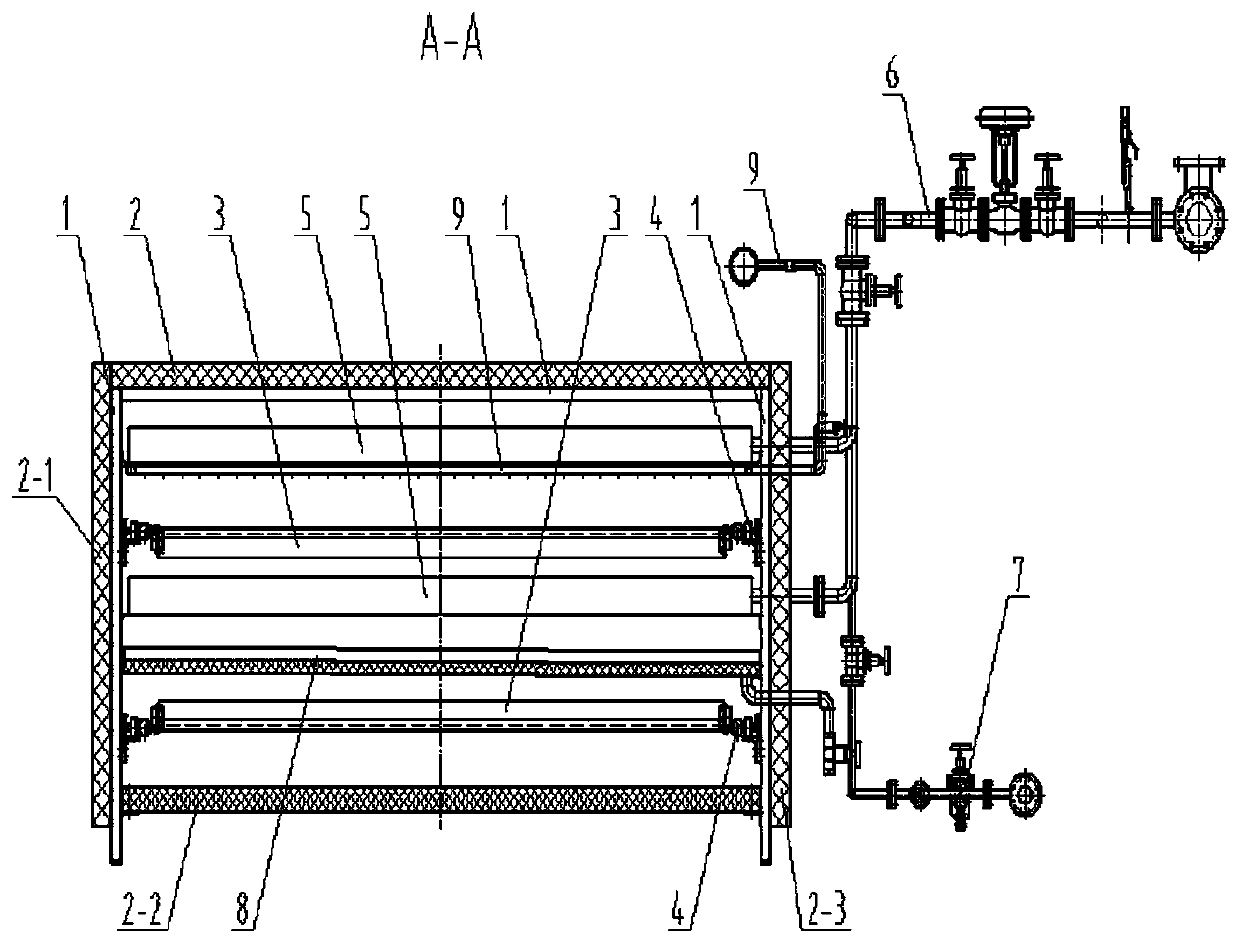

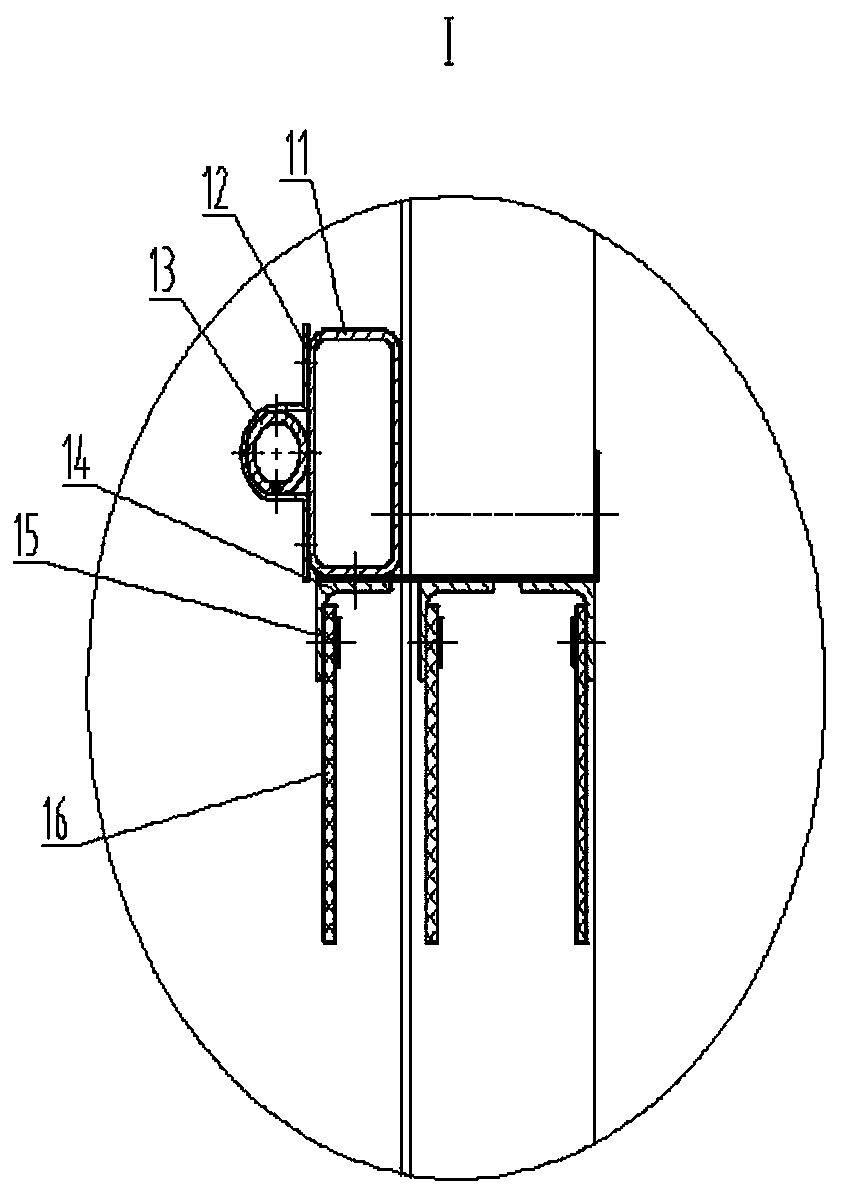

[0021] figure 1 , 2 As shown, the equipment suitable for curing and heat preservation of the present invention is composed of several modular unit sections; each unit includes a frame 1, a curtain plate 3 connected between the left and right closed-loop chains 4, and a radiator 5 , steam inlet pipeline 6, return water pipeline 7, water receiving box 8 and steam heating pipeline 9; The frame 1 is composed of two side frames and a middle cross brace, which are connected and fixed by fasteners; The top of the frame is fixedly provided with a top heat insulation layer 2, the bottom heat insulation layer 2-2 is fixedly provided on the cross brace located at the bottom of the frame, and the side heat insulation layer is fixedly provided on one side of the frame 2-3. On the other side of the frame, a side-mounted insulation door 2-1 is hingedly installed; at both ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com