Embossed three-dimensional embroidery manufacturing method and embroidery product

A technology of three-dimensional embroidery and manufacturing method, which is applied in the field of embroidery to achieve the effect of realizing accurate positioning and realizing diversified designs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

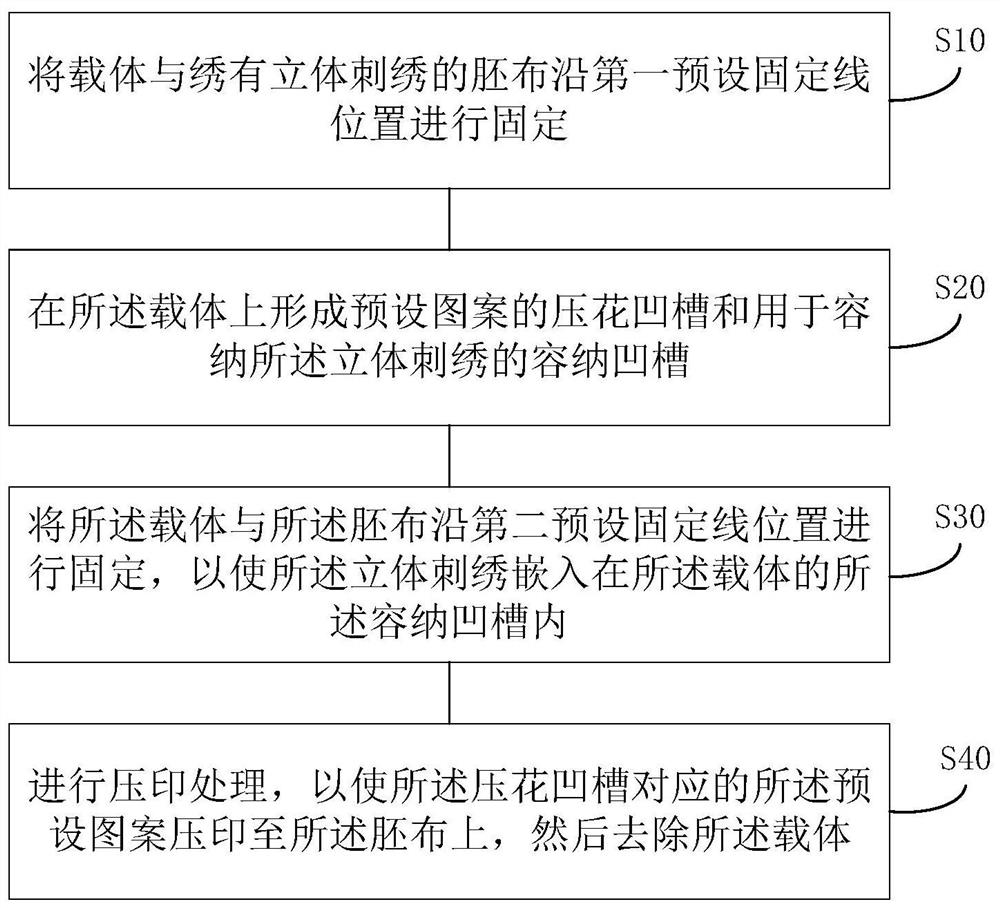

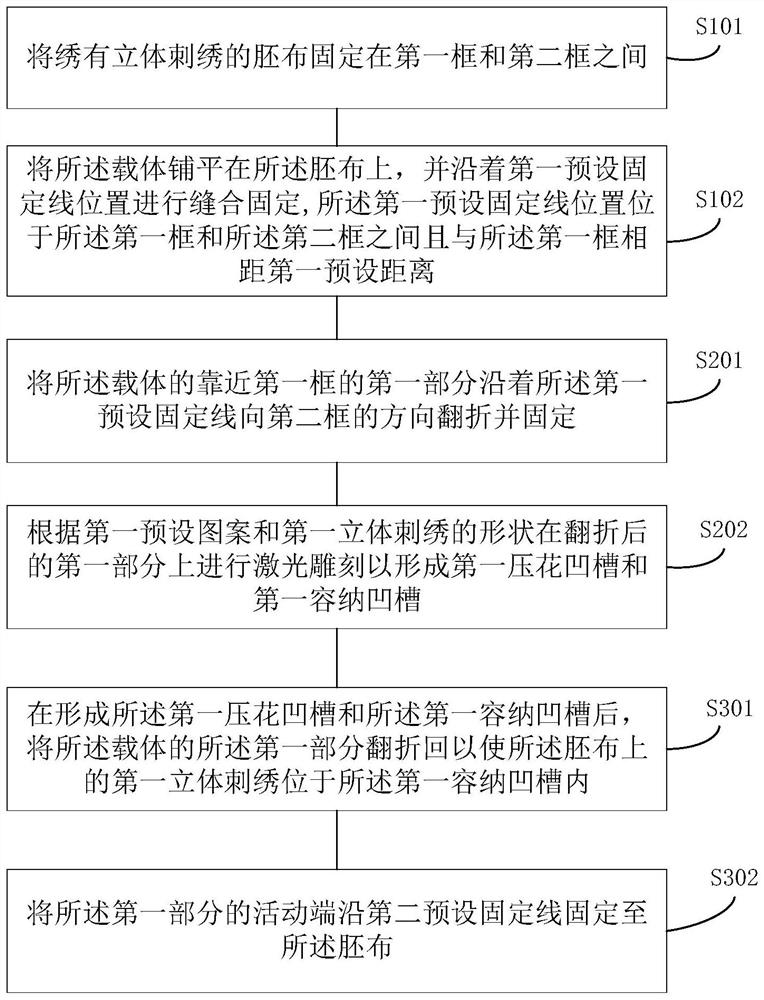

[0051]Please refer toFigure 1 to Figure 7 This embodiment proposes a method for manufacturing embossed three-dimensional embroidery, which can be used for embossing three-dimensional embroidery. The embroidery manufactured by this method not only has various embossing patterns, but also presents three-dimensional embroidery effects, etc., which realizes the Diversified design. In addition, it is easy to realize the positioning of embossing patterns and three-dimensional embroidery on the fabric according to the design of the strip pattern.

[0052]Such asfigure 1 As shown, the method for manufacturing the embossed three-dimensional embroidery will be described below.

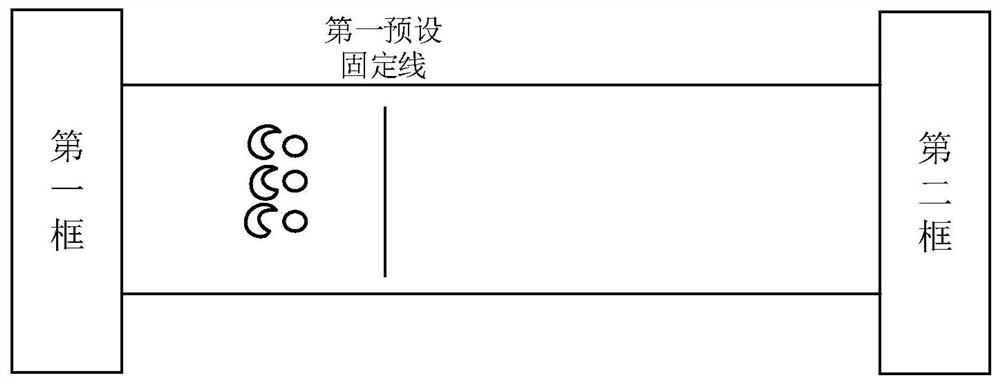

[0053]Step S10, fixing the carrier and the embryo cloth embroidered with three-dimensional embroidery along the first preset fixing line position. In this embodiment, the carrier has a certain thickness, so that embossing grooves and receiving grooves can be formed during laser engraving. Wherein, the formed groove may b...

Embodiment 2

[0090]Based on the embossed three-dimensional embroidery manufacturing method of the above-mentioned embodiment 1, this embodiment proposes an embroidery, which has embossed patterns and three-dimensional embroidery. Wherein, the embossing pattern is obtained by embossing grooves formed on the carrier in the above embodiment 1, and the three-dimensional embroidery can be obtained by using steps S111-S112 or S111-S113 in the above embodiment 1. Wherein, the embossed pattern on the embroidery is located at the preset position of the three-dimensional embroidery.

[0091]It can be understood that the embroidery in this embodiment corresponds to the embossed three-dimensional embroidery manufacturing method in the above-mentioned embodiment 1, and the optional options in this method are also applicable to the embroidery in this embodiment, so it will not be detailed here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com