Preparation method of hollow cactus-shaped carbon plate-carbon nanotubes

A technology of carbon nanotubes and cactus, which is applied in the field of preparation of electrocatalytic carbon materials, can solve the problems of high toxicity of reagents, failure to greatly improve the performance of ZIF-derived carbons, and cumbersome and complicated synthesis processes, and achieve strong variability and easy The effect of control modification and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Dissolve 5.0 g of 2-methylimidazole in 100 mL of deionized water, and stir for 10 min.

[0025] (2) 1.32g of Zn(NO 3 ) 2 ·6H 2 O and 0.33g of Co(NO 3 ) 2 ·6H 2 O was dissolved in 100 mL deionized water, added to the solution in step 1, and stirred at room temperature for 3 h.

[0026] (3) Dissolve 0.5 g of dopamine hydrochloride in 20 mL of deionized water, add the solution in step 2, and continue stirring at room temperature for 8 h.

[0027] (4) The black precipitate was collected by centrifugation at 2000r / min, centrifuged for 5min, and washed repeatedly with deionized water and ethanol for 3 times respectively. After drying, the composite ZIFs@PDA was obtained.

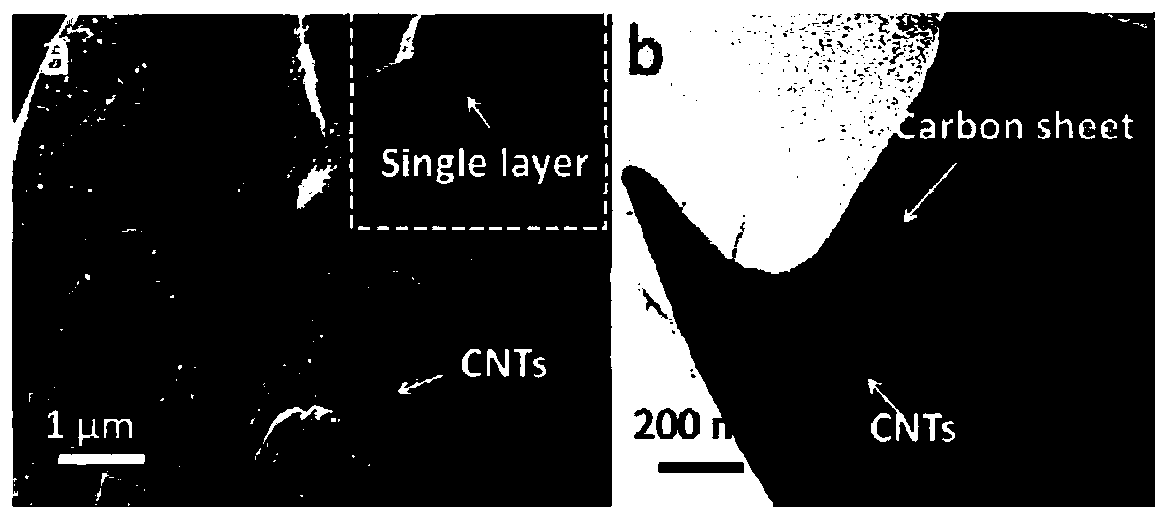

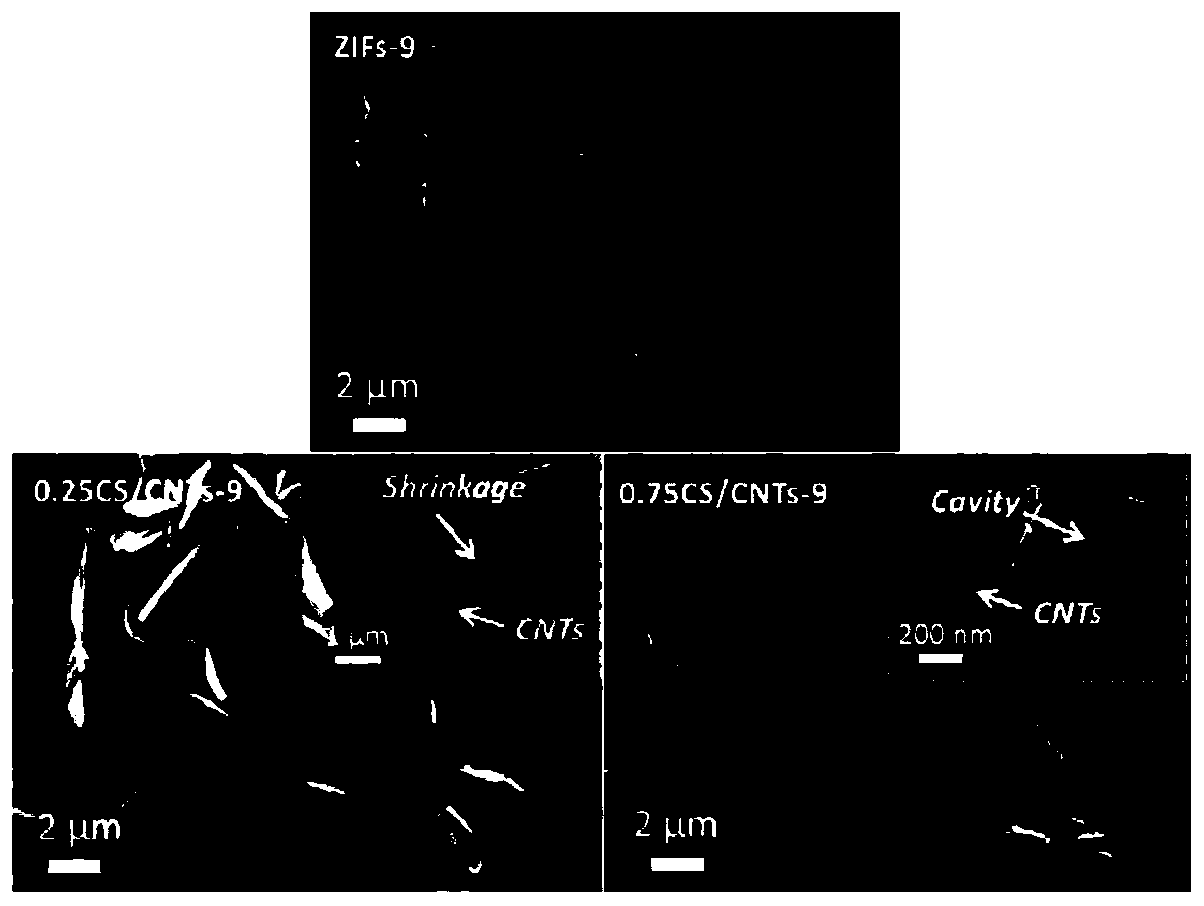

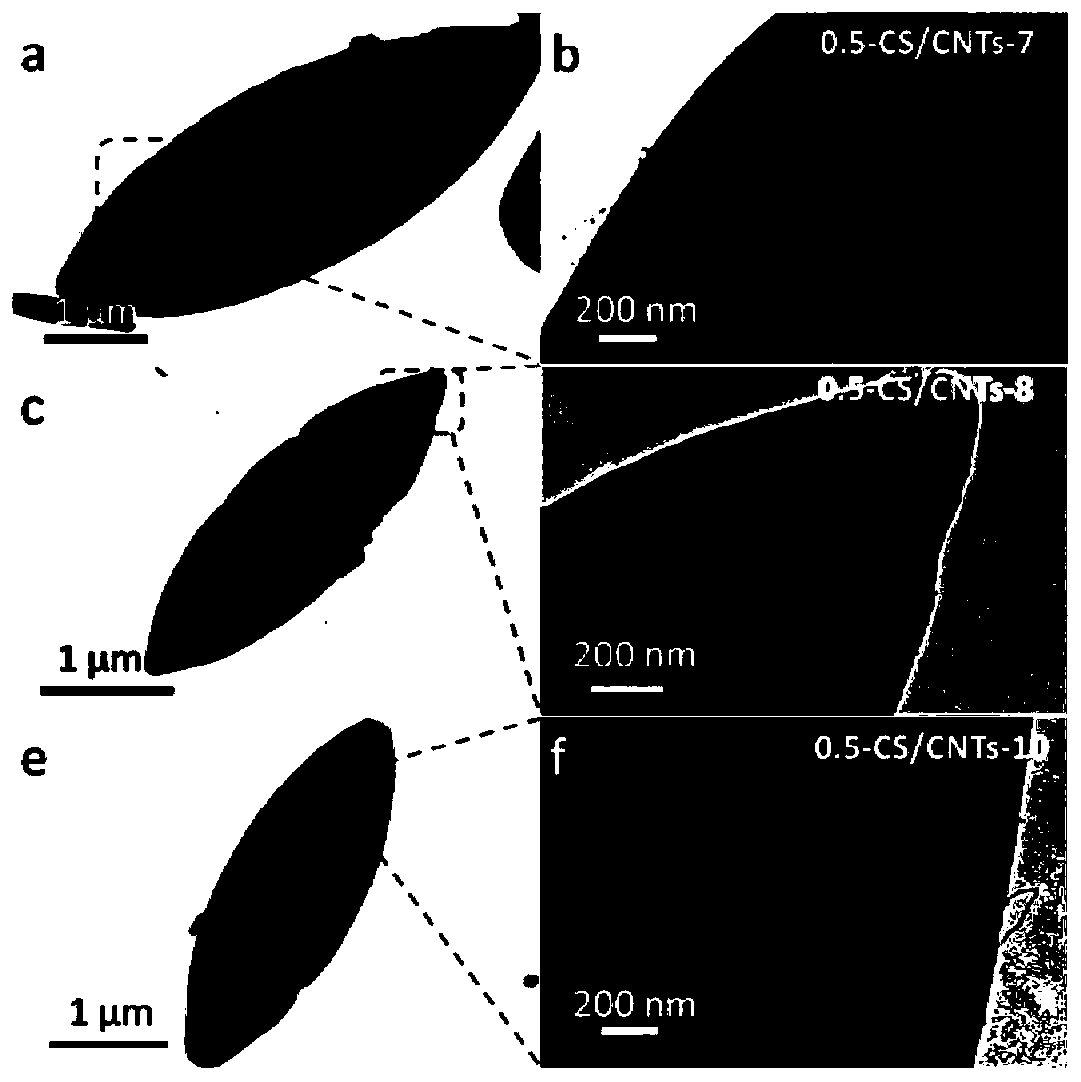

[0028] (5) Carry out high-temperature carbonization in a nitrogen atmosphere at 900 °C, and perform acid treatment to finally obtain 0.5-CS / CNTs-9.

Embodiment 2

[0035] (1) Dissolve 5.0 g of 2-methylimidazole in 100 mL of deionized water, and stir for 10 min.

[0036] (2) 1.32g of Zn(NO 3 ) 2 ·6H 2 O and 0.33g of Co(NO 3 ) 2 ·6H 2 O was dissolved in 100 mL deionized water, added to the solution in step 1, and stirred at room temperature for 3 h.

[0037] (3) Dissolve 0.25 g of dopamine hydrochloride in 20 mL of deionized water, add the solution in step 2, and continue stirring at room temperature for 8 h.

[0038] (4) The black precipitate was collected by centrifugation at 2000r / min, centrifuged for 5min, and washed repeatedly with deionized water and ethanol for 3 times respectively. After drying, the composite ZIFs@PDA was obtained.

[0039] (5) Carry out high-temperature carbonization in a nitrogen atmosphere at 900 °C, and perform acid treatment to finally obtain 0.25-CS / CNTs-9.

Embodiment 3

[0041] (1) Dissolve 5.0 g of 2-methylimidazole in 100 mL of deionized water, and stir for 10 min.

[0042] (2) 1.32g of Zn(NO 3 ) 2 ·6H 2 O and 0.33g of Co(NO 3 )2 ·6H 2 O was dissolved in 100 mL deionized water, added to the solution in step 1, and stirred at room temperature for 3 h.

[0043] (3) Dissolve 0.75 g of dopamine hydrochloride in 20 mL of deionized water, add the solution in step 2, and continue stirring at room temperature for 8 h.

[0044] (4) The black precipitate was collected by centrifugation at 2000r / min, centrifuged for 5min, and washed repeatedly with deionized water and ethanol for 3 times respectively. After drying, the composite ZIFs@PDA was obtained.

[0045] (5) Carry out high-temperature carbonization in a nitrogen atmosphere at 900 °C, and perform acid treatment, and finally obtain 0.75-CS / CNTs-9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com