Intelligent visual welding device

A welding device and intelligent vision technology, which is applied in the field of intelligent visual welding devices, can solve the problems of manpower occupation and inability to apply, and achieve the effect of saving expenses, reducing labor costs, and loosening requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

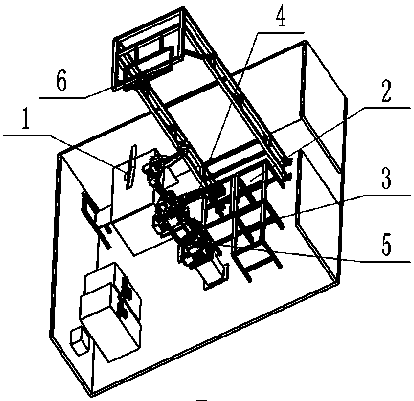

[0017] Such as figure 1 The intelligent visual welding device includes a workstation 1 , a feeding workbench 2 , a welding workbench 3 , a handling industrial robot 4 , a welding industrial robot 5 and a vision system 6 . Specifically:

[0018] Workstation, used to receive data, perform data calculation and issue instructions;

[0019] Loading table, used to hold workpieces;

[0020] The welding workbench is used for welding industrial robots to perform welding operations;

[0021] The vision system is equipped with an independent coordinate system based on the position of multiple cameras for fixed-point recognition and spatial coordinate compensation; it is used to receive the three-dimensional digital and analog data of the workpiece transmitted from the workstation; it is used to take pictures and read the workpiece on the loading table and communicate with it. The three-dimensional digital and analog data is compared to identify and judge the workpiece, and at the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com