Mini perfume pump structure with external spring

An external type, perfume technology, applied in the types of packaging items, applications, special packaging items, etc., can solve the problems of complex processing and manufacturing, high production costs, and many structural parts, and achieve stable spray volume, simple assembly, and high air pump speed. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

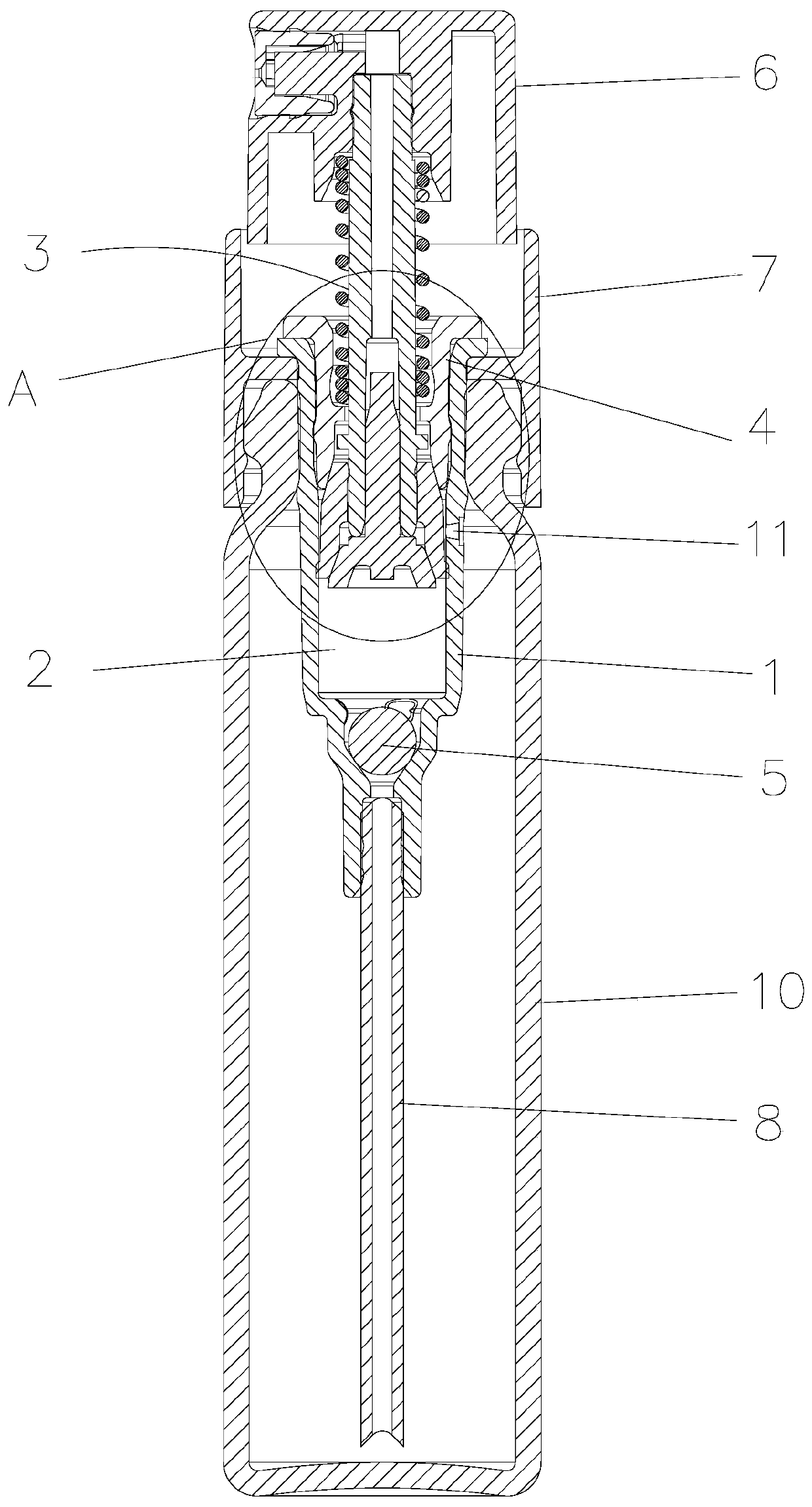

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

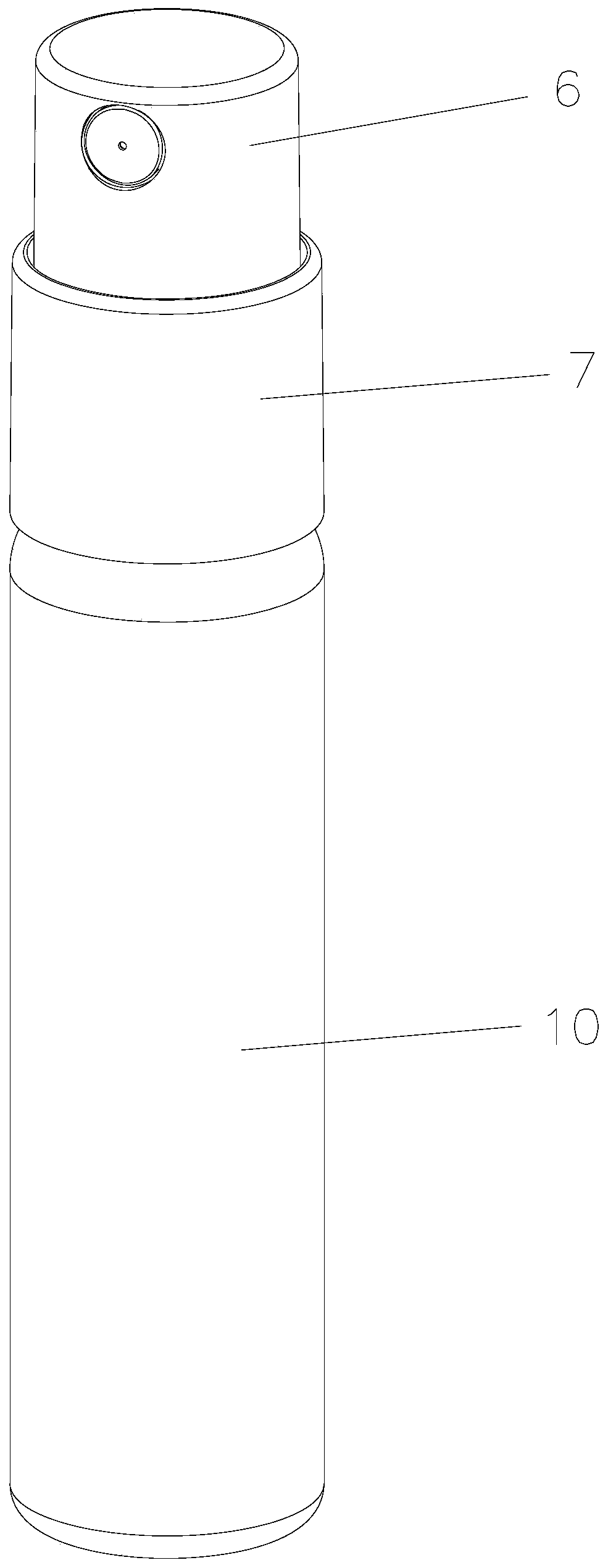

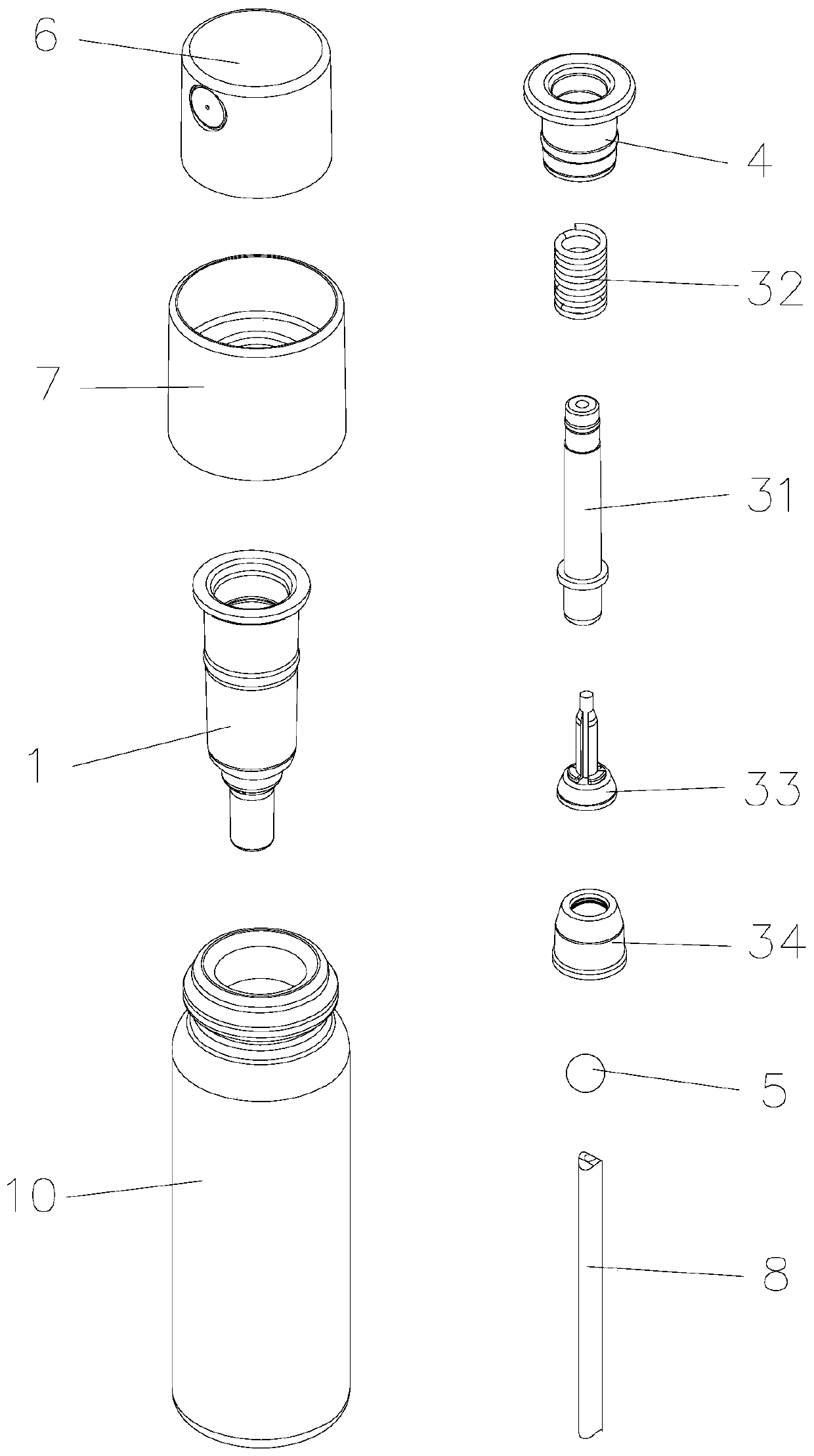

[0024] Such as Figure 1 to Figure 6 As shown, a miniature spring external type perfume pump structure includes a pump body 1 extending into the bottle body 10, and a pump chamber 2 is arranged on the pump body 1, and a pump chamber 2 that can move up and down in the pump chamber 2 is provided. The suction assembly 3 that moves to extract the liquid in the bottle upwards. The pump body 1 and the upper end of the pump chamber 2 are connected with a locking cover 4 that can prevent the suction assembly 3 from coming out of the pump chamber 2. The lower end of the pump chamber 2 is provided with a one-way valve 5 that only allows the liquid in the bottle to discharge upward when the suction assembly 3 moves, and the upper end of the suction assembly 3 is connected with a button 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com