Method for improving quality of room-temperature marinated eggs by far-infrared radiation assisted hot-air drying

A technology of far-infrared radiation and far-infrared drying, applied in the field of food, can solve the problems of low energy utilization rate, decreased elasticity, slow heat diffusion, etc., and achieve the effect of improving uneven heating, promoting diffusion to the surface, and spreading heat loss with little loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for improving the quality of normal-temperature marinated eggs by assisted hot air drying by far-infrared radiation, comprising the following steps:

[0033](1) Distribute the far-infrared radiation source evenly on the upper layer of the far-infrared drying oven, and set the hot air temperature to 70°C, turn on the blower to preheat the drying oven for 2 hours, until the temperature of each layer in the drying oven is 70±1°C. The hot air speed in the drying box is 2.4m / s; the average far-infrared radiation intensity that the material layer can receive is 17.10±3.09W.m -2 .

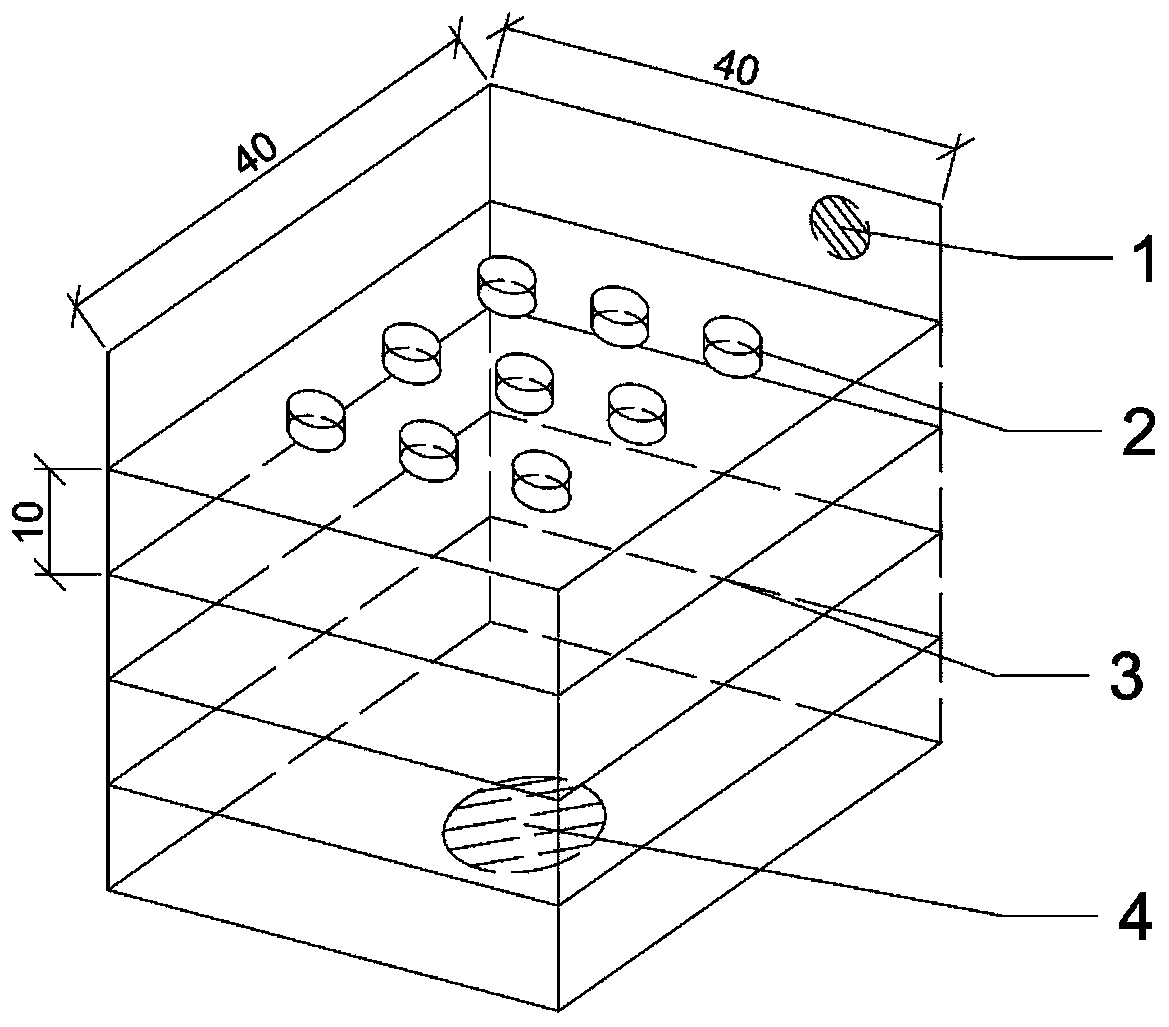

[0034] The structure of the far-infrared drying box is as follows: figure 1 As shown, its interior is a layered material rack layered up and down, the top layer of the material rack is placed on the far-infrared radiation source 2, and the other layers of material racks 3 are placed on the marinated eggs to be dried; the bottom of the drying box is provided with a blower port 4 , blowing...

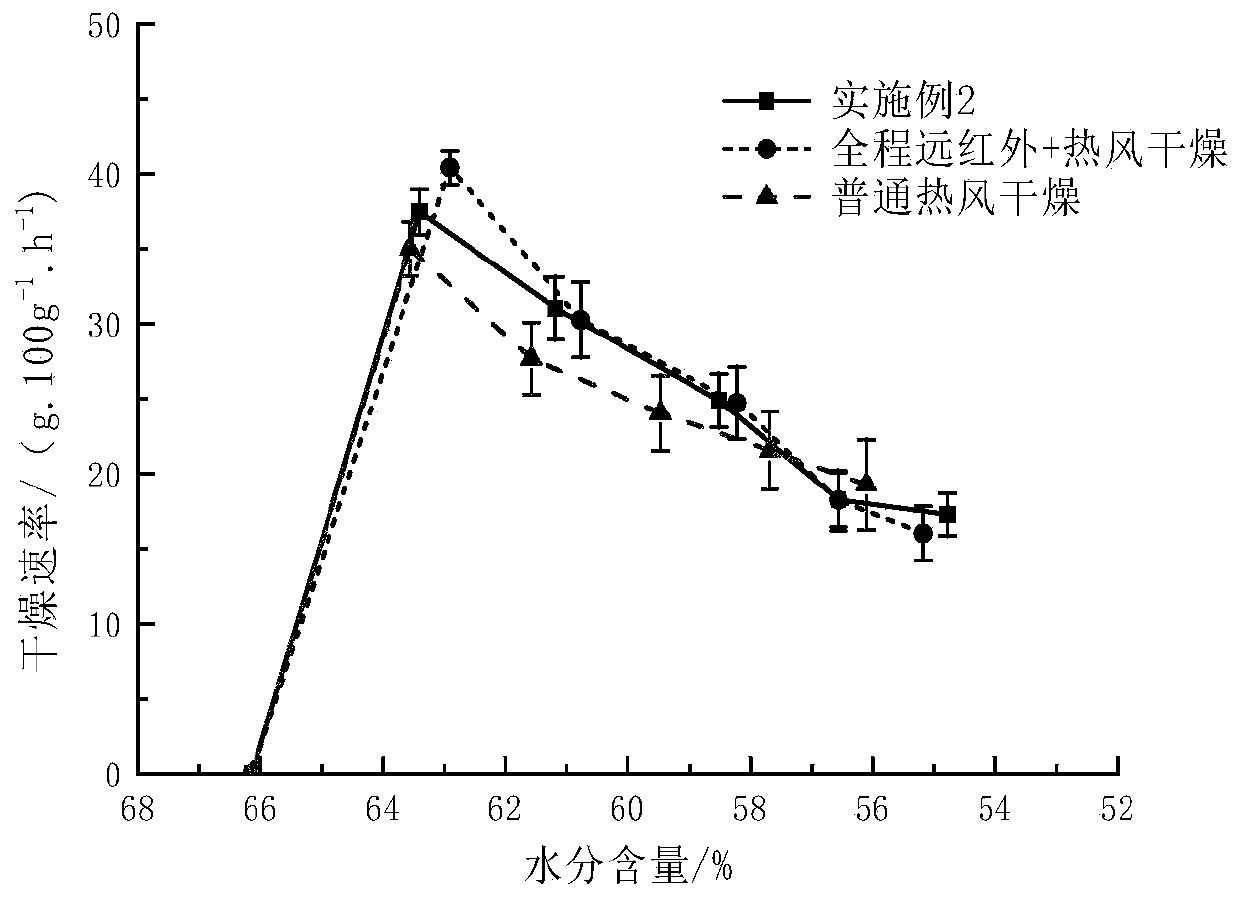

Embodiment 2

[0044] A method for improving the quality of normal-temperature marinated eggs by assisted hot air drying by far-infrared radiation, comprising the following steps:

[0045] (1) Distribute the far-infrared radiation source evenly on the upper layer of the far-infrared drying oven, and set the hot air temperature to 65°C, turn on the blower to preheat the drying oven for 2 hours, until the temperature of each layer in the drying oven is 65±1°C. The hot air speed in the drying box is 2.4m / s; the average far-infrared radiation intensity that the material layer can receive is 15.63±3.52W.m -2 .

[0046] (2) Select eggs with complete shape and uniform size. The average mass of the eggs is 37.14±2.37g, put them in boiling water for 20 minutes, remove the shells after fully ripening, and drain the water;

[0047] (3) Put the shelled eggs into the marinade according to the ratio of material to liquid 1:1.2, and marinate in a water bath for 55 minutes at 80°C;

[0048] (4) Lay the ma...

Embodiment 3

[0054] A method for improving the quality of normal-temperature marinated eggs by assisted hot air drying by far-infrared radiation, comprising the following steps:

[0055] (1) Distribute the far-infrared radiation source evenly on the upper layer of the far-infrared drying oven, and set the hot air temperature to 60°C, turn on the blower to preheat the drying oven for 2 hours, until the temperature of each layer in the drying oven is 60±1°C. The hot air speed in the drying box is 2.4m / s; the average far-infrared radiation intensity that the material layer can receive is 13.91±3.55W.m -2 .

[0056] (2) Select quail eggs with complete shape and uniform size, the average mass of quail eggs is 8.79±0.36g, put them in boiling water for 15 minutes, take out the shells after fully ripening, and drain the water;

[0057] (3) Put the shelled quail eggs into the marinade according to the ratio of material to liquid 1:1.2, and marinate in a water bath for 40 minutes at 80°C;

[0058]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com