Multi-station reinforcing sheet laminating device for flexible circuit board production

A flexible circuit board and bonding device technology, which is applied in the direction of circuit bendable/stretchable parts, printed circuit parts, printed circuit secondary processing, etc., to avoid manual feeding, easy repair and maintenance, increase The effect of the fit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

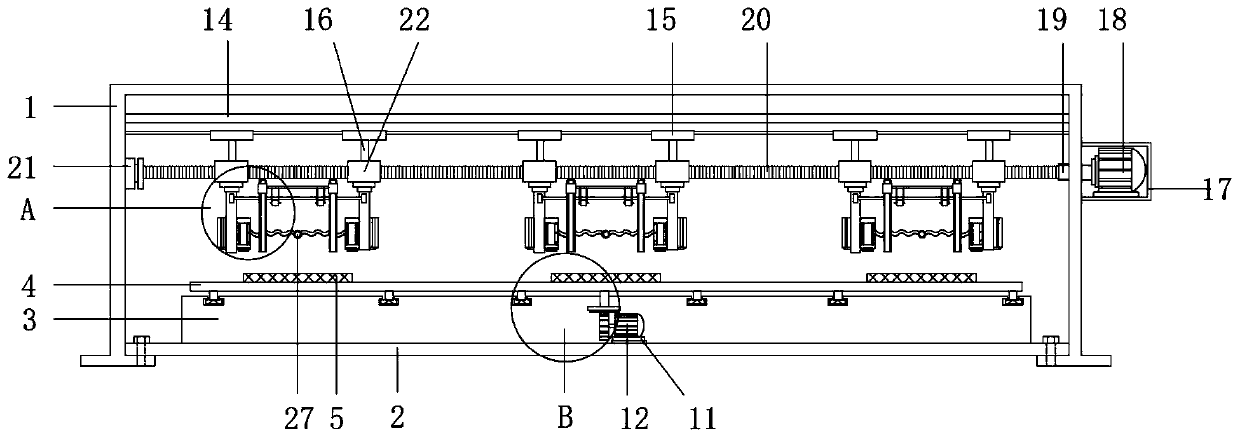

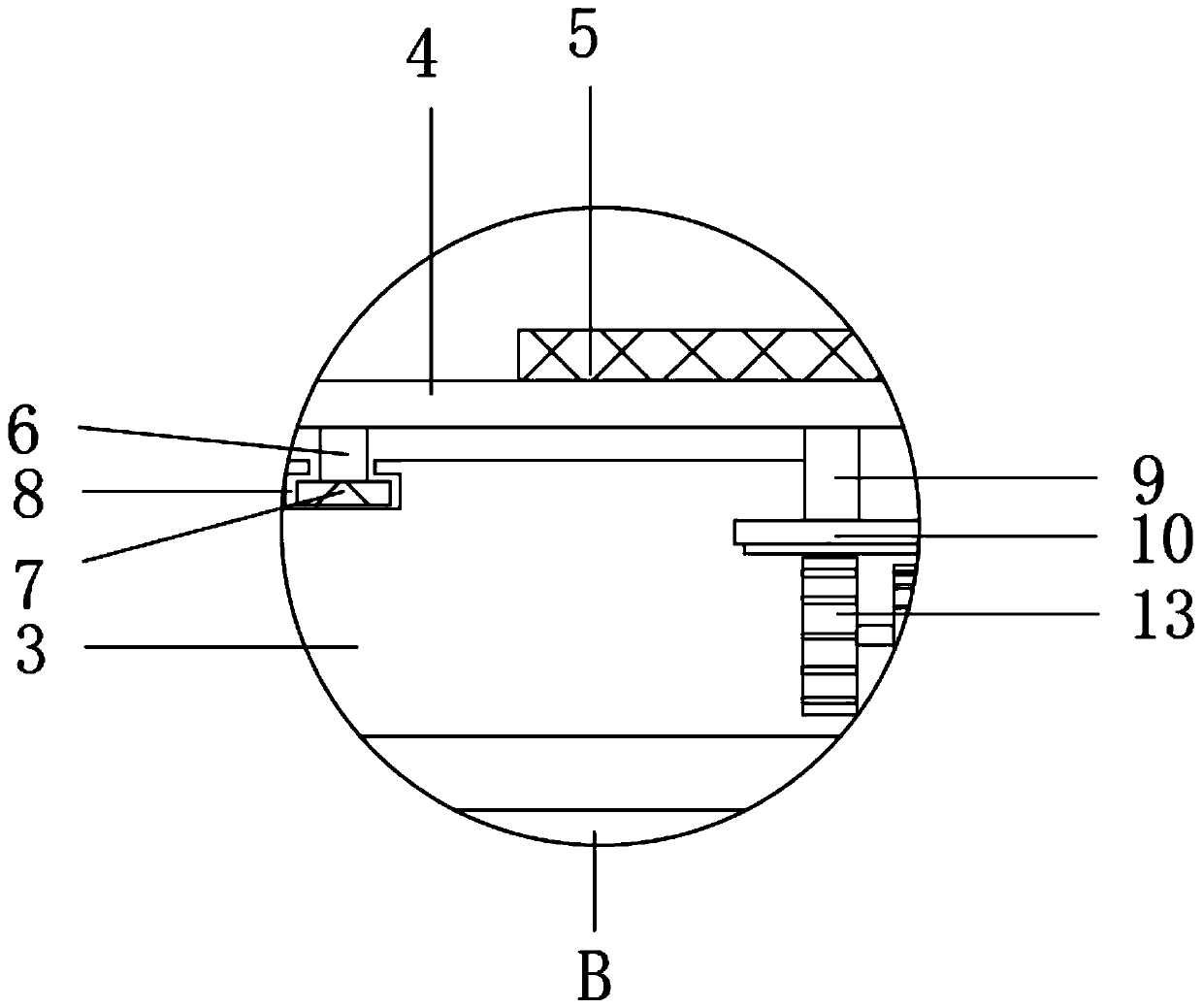

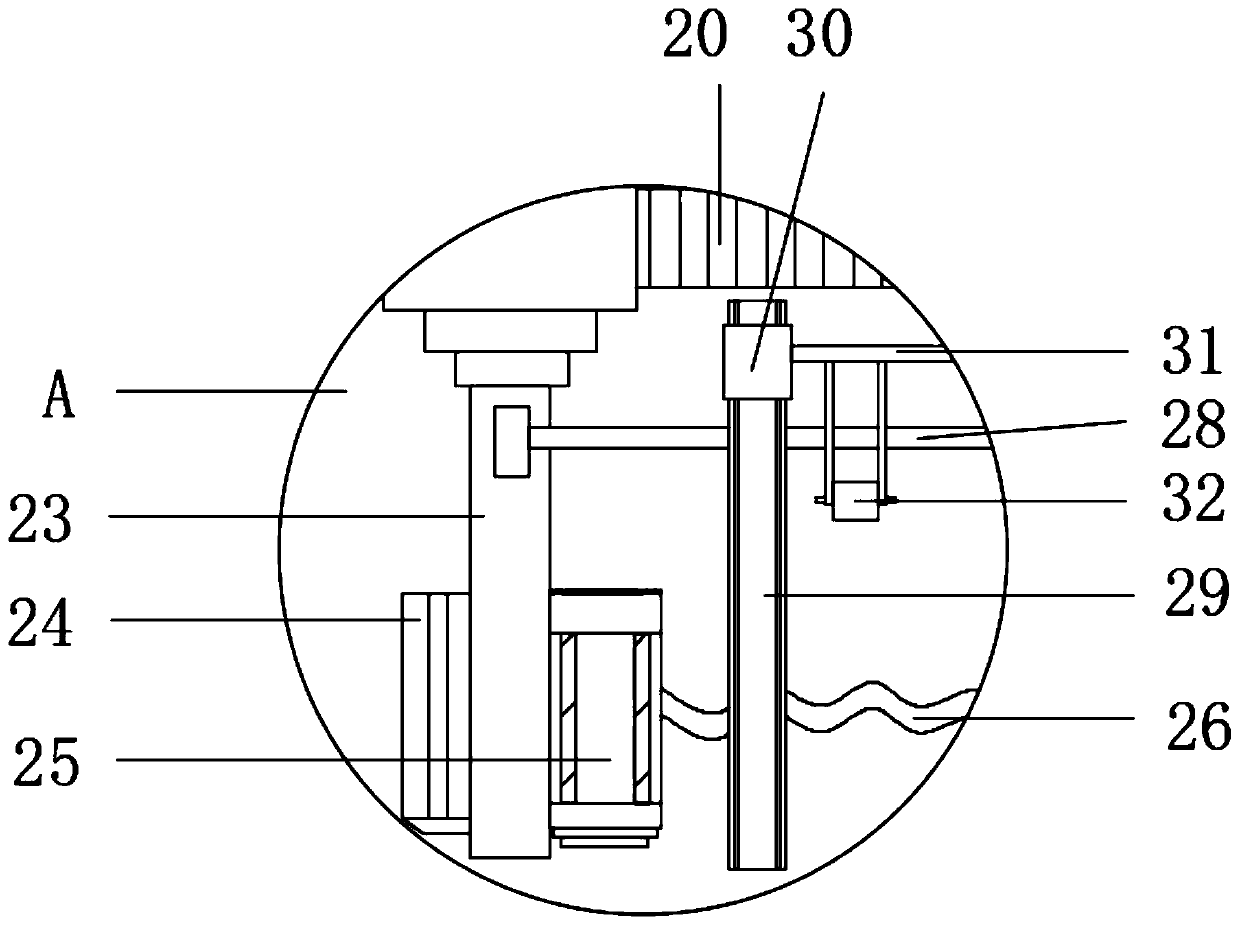

[0019] Such as Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: a multi-station reinforcing sheet bonding device for flexible circuit board production, including a fixed bracket 1, and the fixed connection between the two side walls at the bottom of the fixed bracket 1 There is a welding bottom plate 2, the upper end of the welding bottom plate 2 is provided with a workbench 3, and the surface of the workbench 3 away from the welding bottom plate 2 is evenly provided with a number of chute 8, and a No. 1 slider 7 is slidably connected in the chute 8 , the top of the workbench 3 is provided with a mobile carrier 4, and the bottom surface of the mobile carrier 4 is fixedly connected with a number of No. The end of the No. connecting rod 6 away from the mobile carrier 4 is fixedly connected to the No. 1 slider 7, and the mobile carrier 4 is slidably connected to the chute 8 through the No. 1 connecting rod 6 and the No. 1 slider 7. The work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com