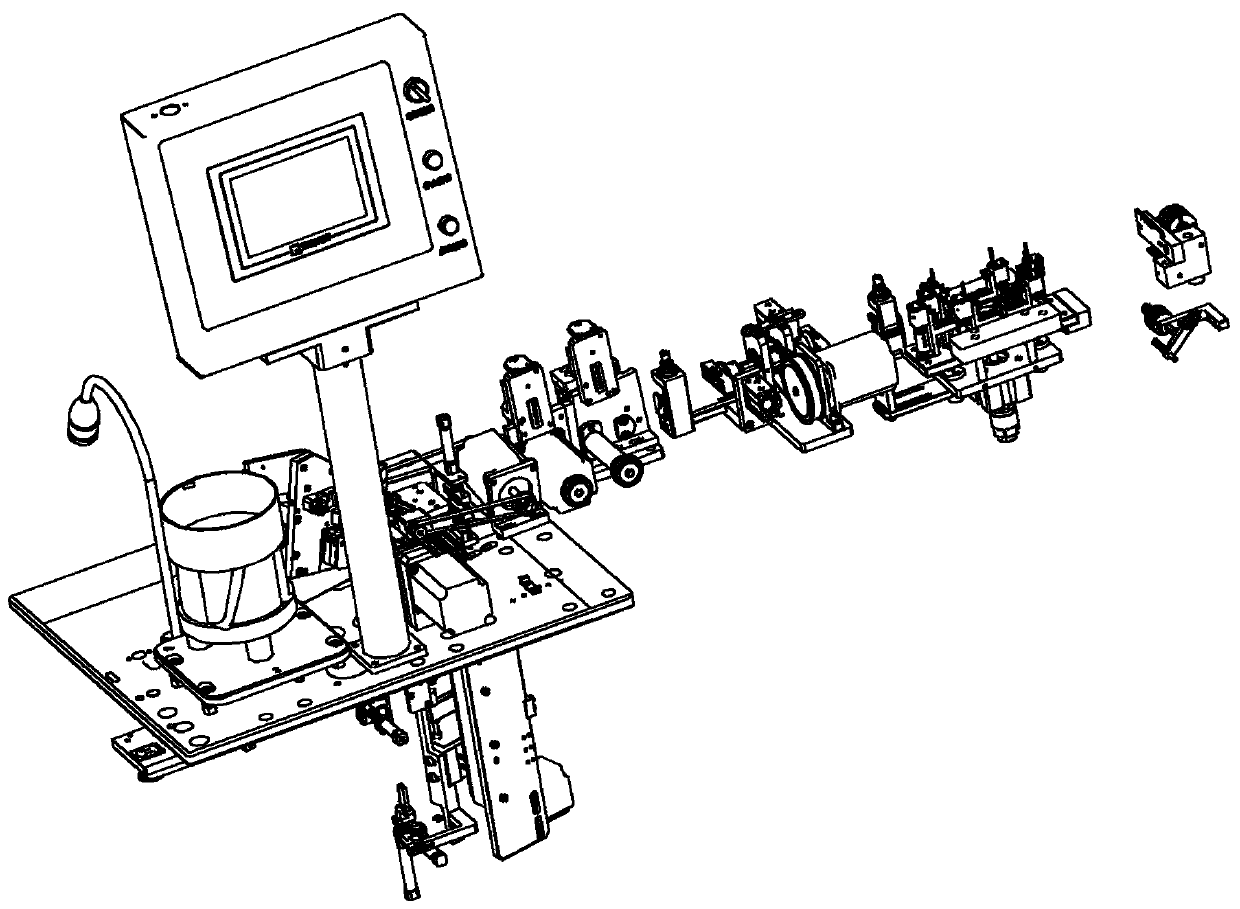

Wire dividing mechanism, four-wire winding T2 equipment and wire winding method

A technology of splitting and driving mechanism, applied in coil manufacturing and other directions, can solve the problems of cluttered wire ends, high labor cost, easy to follow rotation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

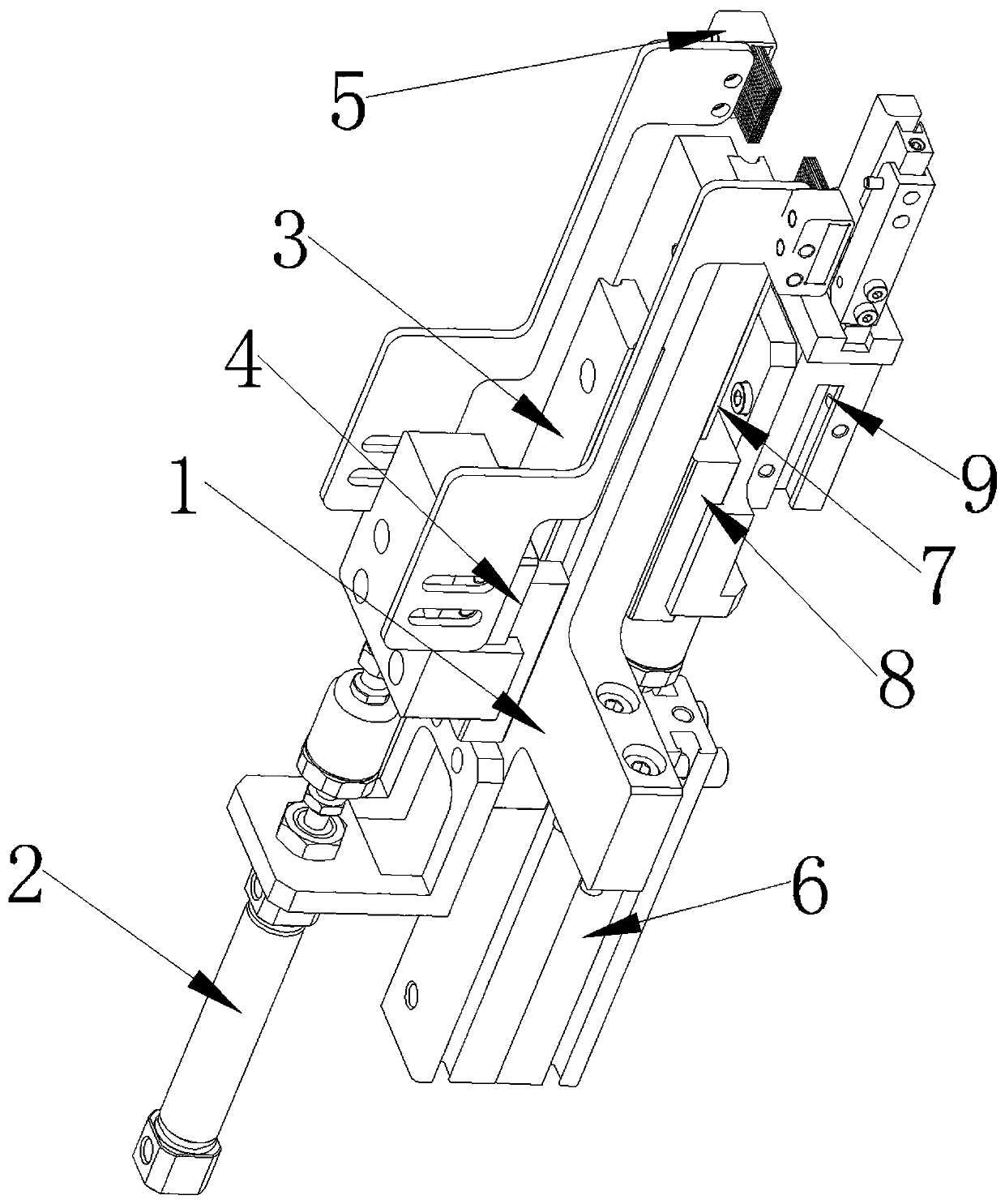

[0024] like Figure 1 to Figure 4 As shown, in this embodiment, the wire distribution mechanism includes a fixed seat 1, a clamping assembly and a wire distribution assembly, and the wire distribution assembly includes a first cylinder 2, a first linear slide rail 3, a first slider 4 and a pair of brush heads 5, the first cylinder 2 and the first linear slide 3 are fixed on the fixed seat 1, the first slider 4 and the piston of the first cylinder 2 The rod is fixedly connected, the first slider 4 is slidingly matched with the first linear slide rail 3, and a pair of brush heads 5 are respectively fixed on both sides of the first slider 4 and the bristles are arranged facing each other. The clamping assembly is fixed on the fixing seat 1, and the clamping assembly clamps the wire end and cooperates with the external twisting mechanism.

[0025] The clamping assembly includes a second cylinder 6, a second linear slide rail 7, a second slider 8 and a gripper cylinder 9, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com