True triaxial multifunctional shearing test device and method for high-temperature and high-pressure hard rock

A shear test, high temperature and high pressure technology, applied in the direction of using a stable shear force to test the strength of materials, measuring devices, and using a stable tension/pressure test to test the strength of materials, etc. The problems of low stiffness and post-peak curve distortion can ensure the long-term steady normal stiffness test, improve the overall stiffness, and reduce the continuous temperature rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

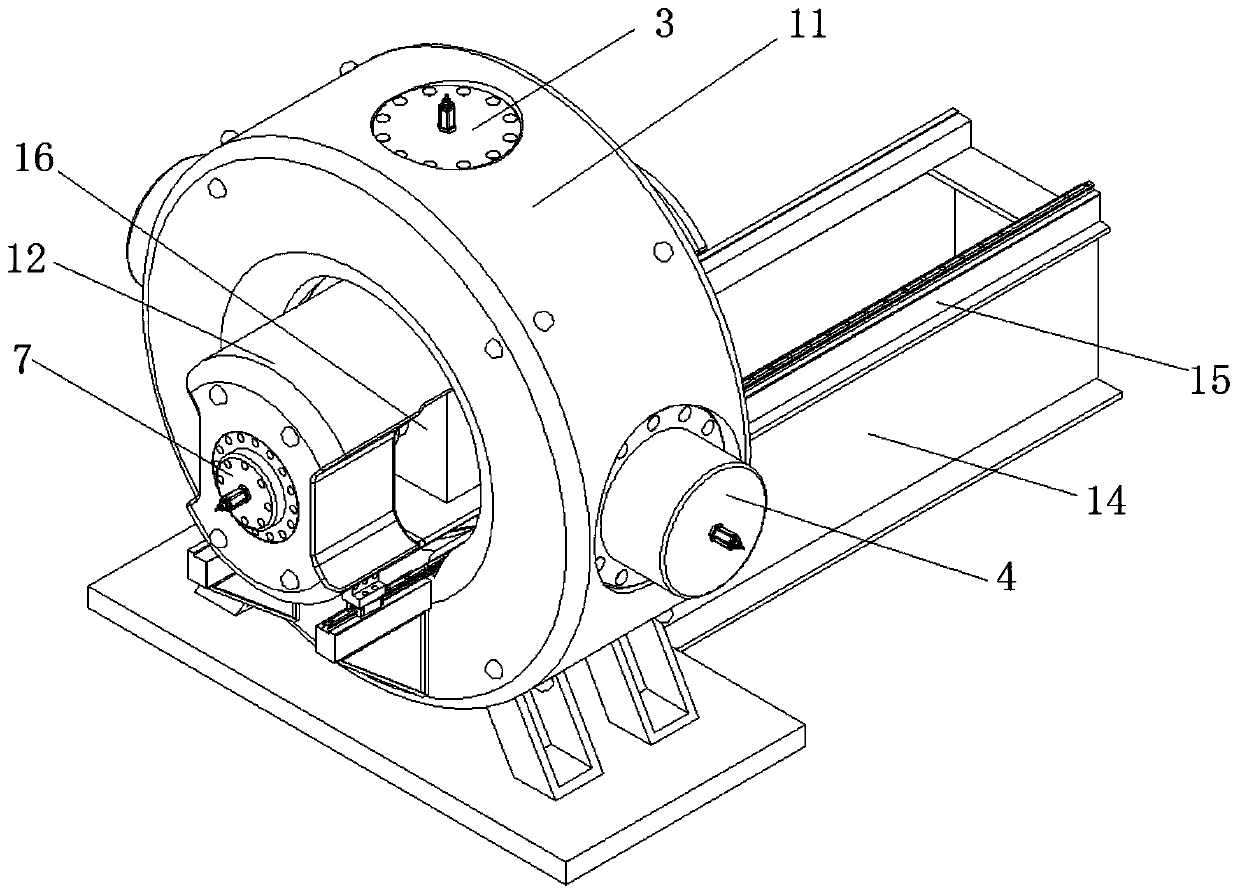

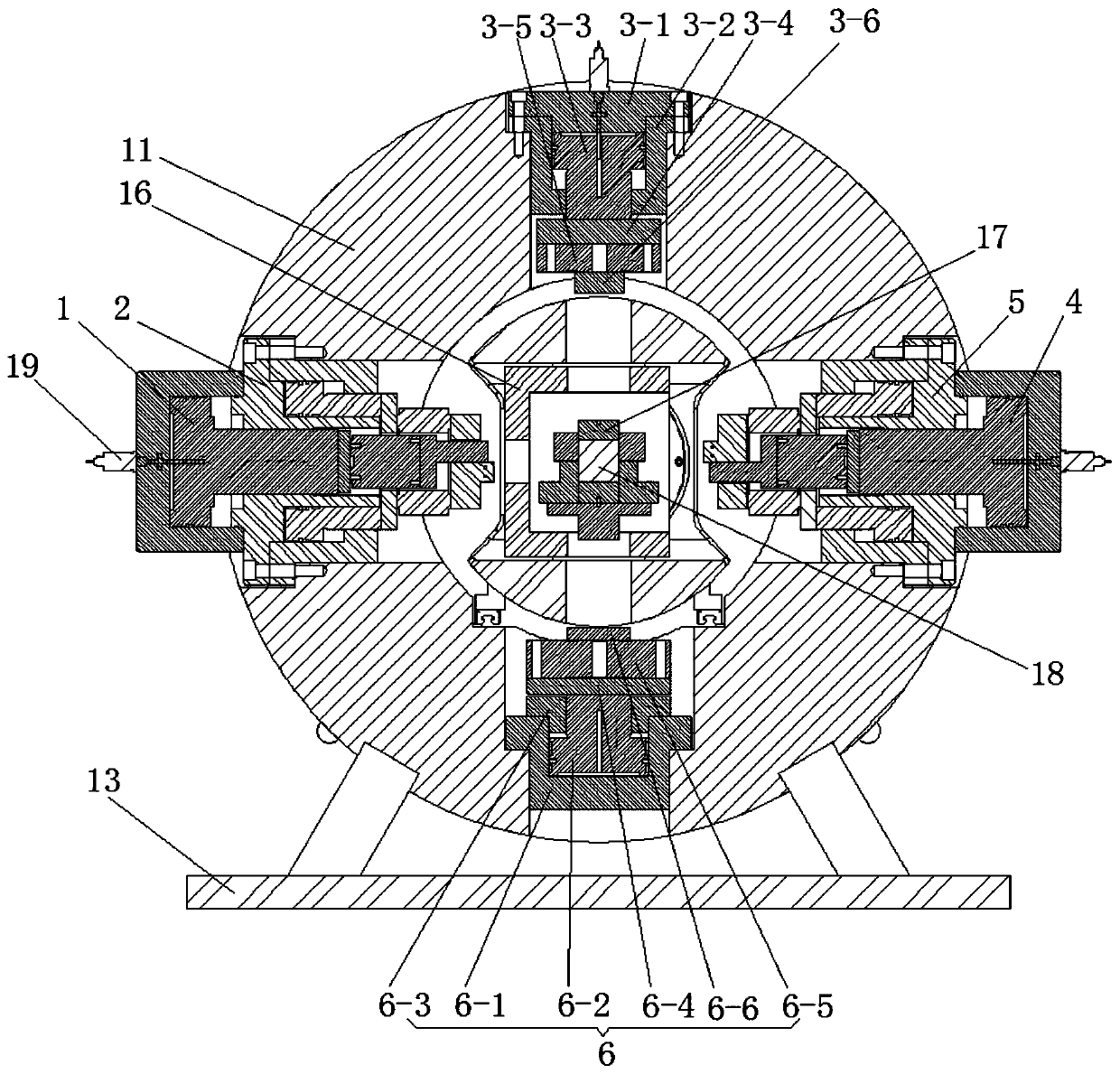

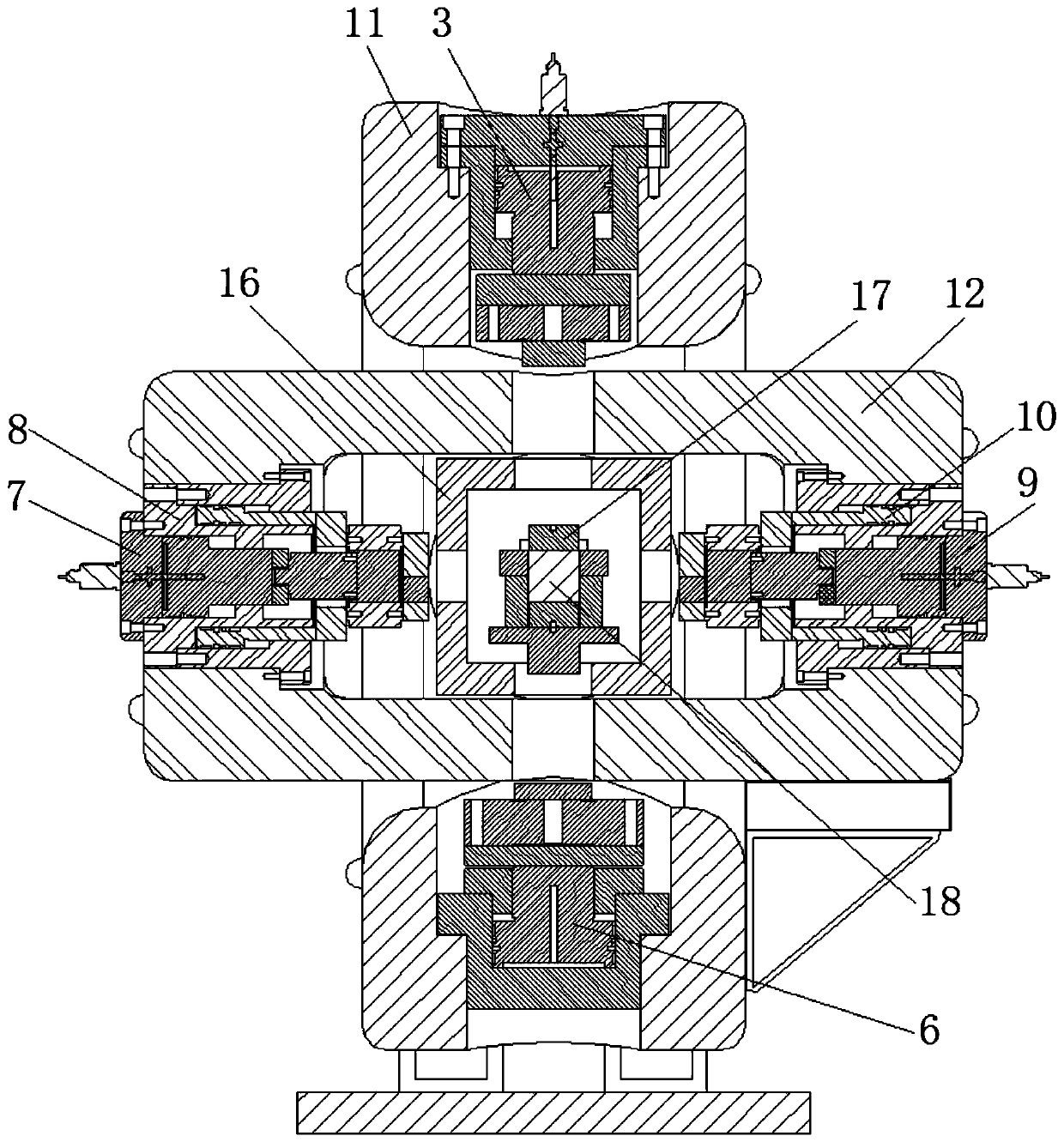

[0042] Such as Figure 1-8 As shown, a high-temperature, high-pressure hard rock true triaxial multifunctional shear test device includes a hydraulic system, a combined tangential loading oil cylinder at the left end, a combined tangential loading oil cylinder at the right end, a combined lateral loading oil cylinder at the front end, and a combined lateral loading oil cylinder at the rear end. Oil cylinder, upper normal load, lower normal load oil cylinder 6, ring frame 11, lateral auxiliary push-pull frame 12, ring frame support platform 13, horizontal support platform 14, test box 16; the upper surface of the ring frame support platform 13 passes Bolts are fixedly installed with an annular frame 11, and the rear end of the annular frame support platform 13 is provided with a horizontal support platform 14, and the horizontal suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com