Anchor rod installing device and trolley with anchor rod installing device

A technology for installing devices and bolts, which is applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc. It can solve the problems of time-consuming and labor-intensive manual installation, and achieve the effects of preventing excessive rotation angle, simplifying the structure and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

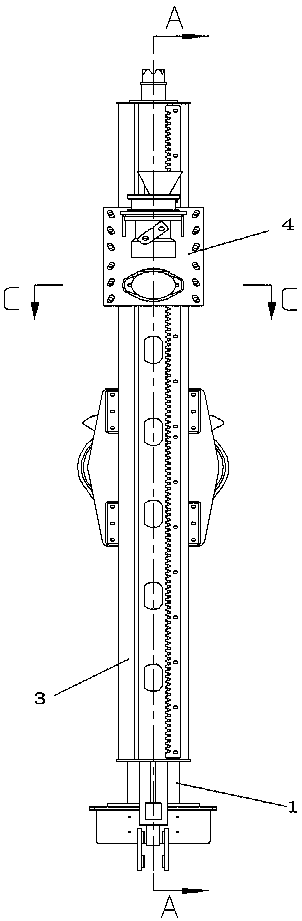

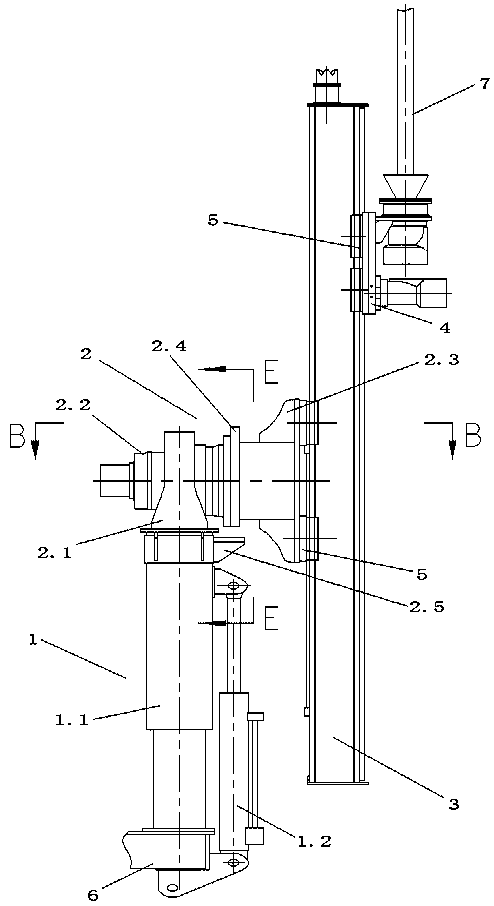

[0042] see Figure 1-9 , a bolt installation device, comprising a height compensation mechanism 1, a rotation mechanism 2, a propulsion mechanism 3 and a mounting mechanism 4, the installation mechanism 4 is slidably arranged on the propulsion mechanism 3, and the propulsion mechanism 3 is arranged on the rotation mechanism 2 and the propulsion mechanism 3 is driven by the rotation mechanism 2 to rotate together with the installation mechanism 4 located on the propulsion mechanism 3. The rotation mechanism 2 is arranged on the height compensation mechanism 1, and the rotation mechanism 2 is realized by the height compensation mechanism 1. , the propulsion mechanism 3 and the installation mechanism 4 carry out height adjustment together, that is, carry out height compensation;

[0043] The propulsion mechanism 3 includes a propulsion beam 3.1, the propulsion beam 3.1 is provided with a first rail 3.11 and a second rail 3.12 arranged along the length direction of the propulsion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com