Firework inner cylinder loading device and process thereof

A filling device and inner cylinder technology, applied in the directions of fireworks, offensive equipment, weapon types, etc., can solve the problems of no danger, low degree of automation, low production efficiency, etc., and achieve high safety performance, high degree of automation, and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

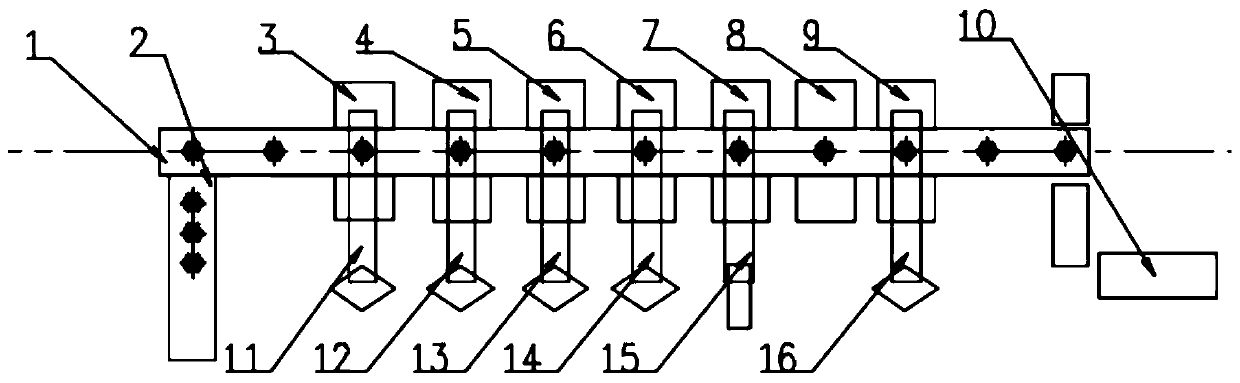

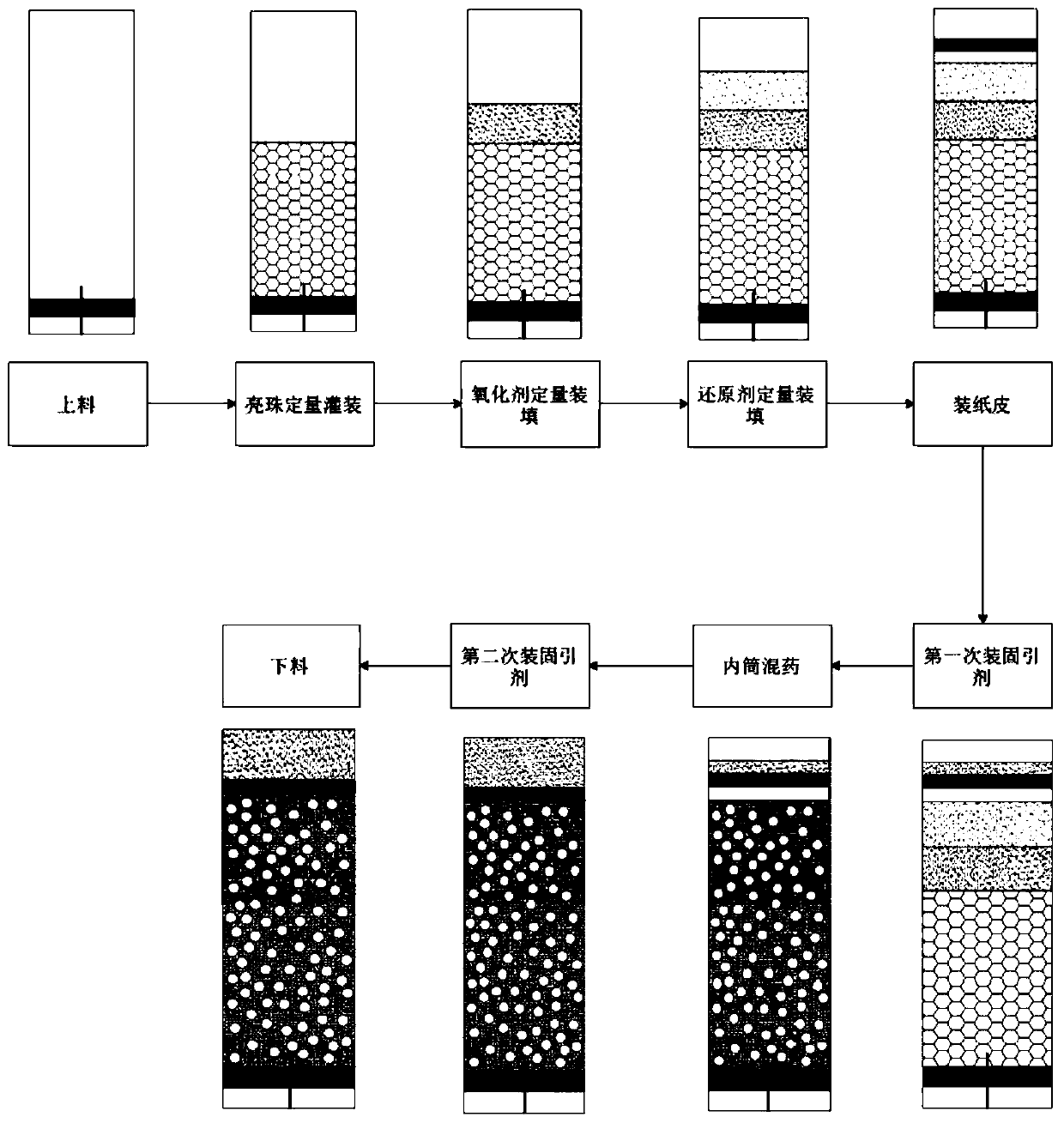

[0036] A kind of firework inner barrel filling device of this embodiment, refer to the attached figure 1 : A kind of firework inner cylinder filling device, comprises conveying device 1, wherein conveying device 1 transmits to the right, and the delivery direction of conveying device 1 is successively provided with bright bead quantitative filling device 3, paper skin device 6, the first loading An oxidant quantitative filling mechanism 4 and a reducing agent quantitative filling mechanism 4 are arranged between the fixing agent device 7, the inner tube mixing device 8 and the second loading fixing agent device 9, and the bright bead quantitative filling device 3 and the paper filling device 6. Mechanism 5, oxidant quantitative filling mechanism 4 is located on the left side of reducing agent quantitative filling mechanism 5, bright bead quantitative filling device 3, oxidant quantitative filling mechanism 4, reducing agent quantitative filling mechanism 5, paper loading device...

Embodiment 2

[0050] A firework inner cylinder filling device, comprising a conveying device 1, wherein the conveying device 1 is transported to the right, and the conveying device 1 is sequentially provided with a bright bead quantitative filling device 3, a paper skin loading device 6, a first-time fixing An oxidant quantitative filling mechanism 4 and a reducing agent quantitative filling mechanism are arranged between the priming agent device 7, the inner tube mixing device 8 and the second loading and priming agent device 9, the bright bead quantitative filling device 3 and the paper filling device 6 5. The oxidant quantitative filling mechanism 4 is located on the right side of the reducing agent quantitative filling mechanism 5. The bright bead quantitative filling device 3, the oxidant quantitative filling mechanism 4, the reducing agent quantitative filling mechanism 5, the paper loading device 6, and the first solidification The primer device 7 and the second fixing primer device 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com