Recycling and filling machine for automobile air conditioner refrigerant and application thereof

A technology for automobile air conditioners and filling machines, which is applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of low energy utilization rate of refrigerant recovery machines, the threat of global warming, and no filling function. The effect of reducing connection leakage, simple structure and improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

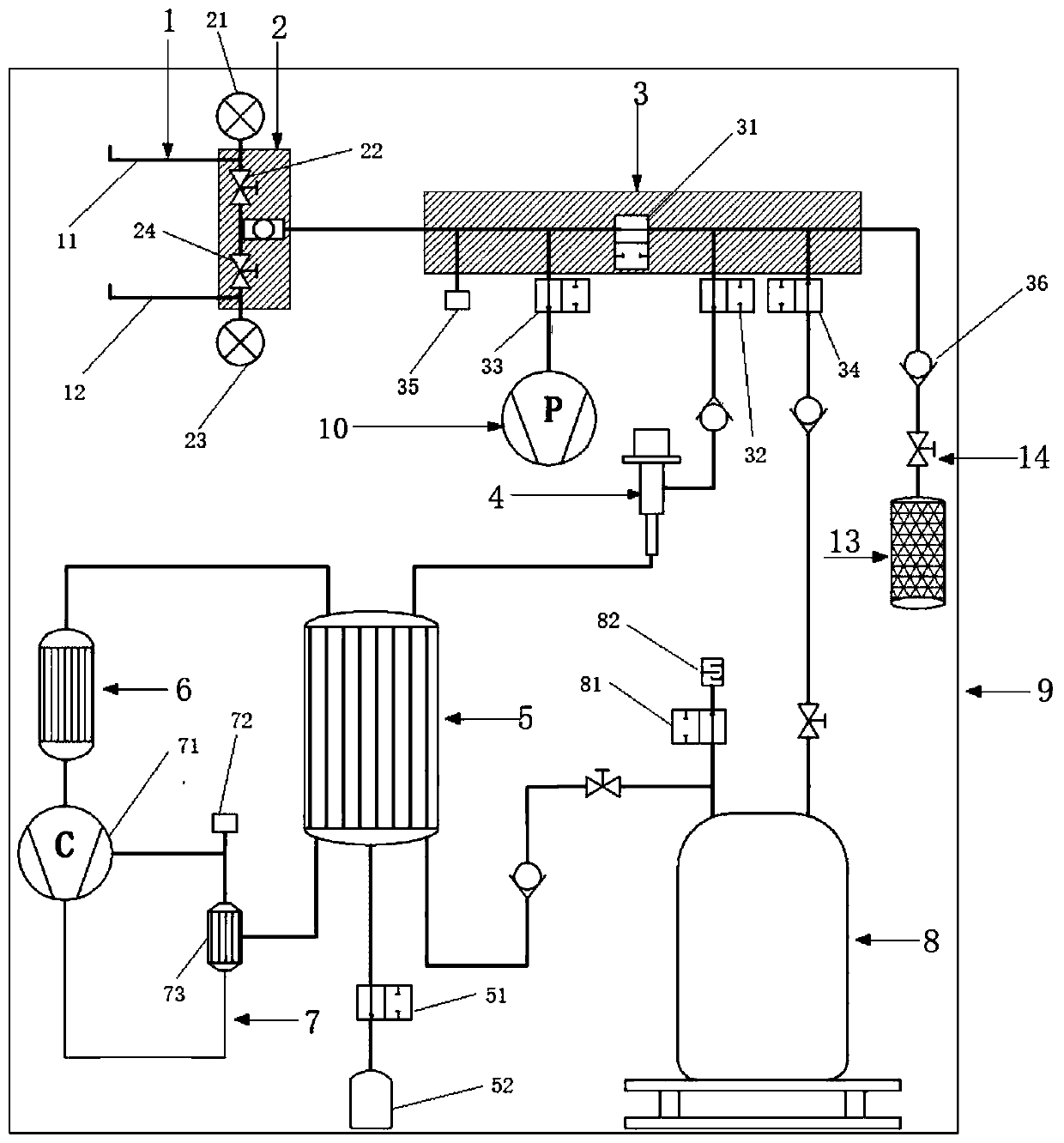

[0046] The refrigerant recovery and filling machine for automobile air conditioners of the present invention has four functions of refrigerant recovery, vacuuming, refrigerant filling and internal refrigerant self-circulation of the device.

[0047] (1) Refrigerant recovery:

[0048] When the refrigerant is recovered, the compressor 71 of the compression mechanism 7 starts to run, and the self-circulation solenoid valve 31 and the recovery solenoid valve 32 are in a conduction state. The refrigerant in the automobile air conditioner enters the refrigerant recovery through the high-pressure valve 22 and the low-pressure valve 23. The refrigerant passes through the self-circulation electromagnetic valve 31, the recovery electromagnetic valve 32, and the one-way valve 36. After being decompressed and vaporized by the expansion valve 4, the refrigerant enters the heat exchange oil separator 5 Degreasing, the gaseous refrigerant after absorbing heat passes through the dry filter 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com