Electrically-driven afterburner and area-adjustable exhaust nozzle integrated structure

A technology for an afterburner and a tail nozzle, which is applied in the field of aero-engines, can solve the problems of difficulty in meeting the structural size of a small aero-turbine engine, low compressor pressure ratio, low manufacturing cost, etc., and achieves compact structure, few accessories, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

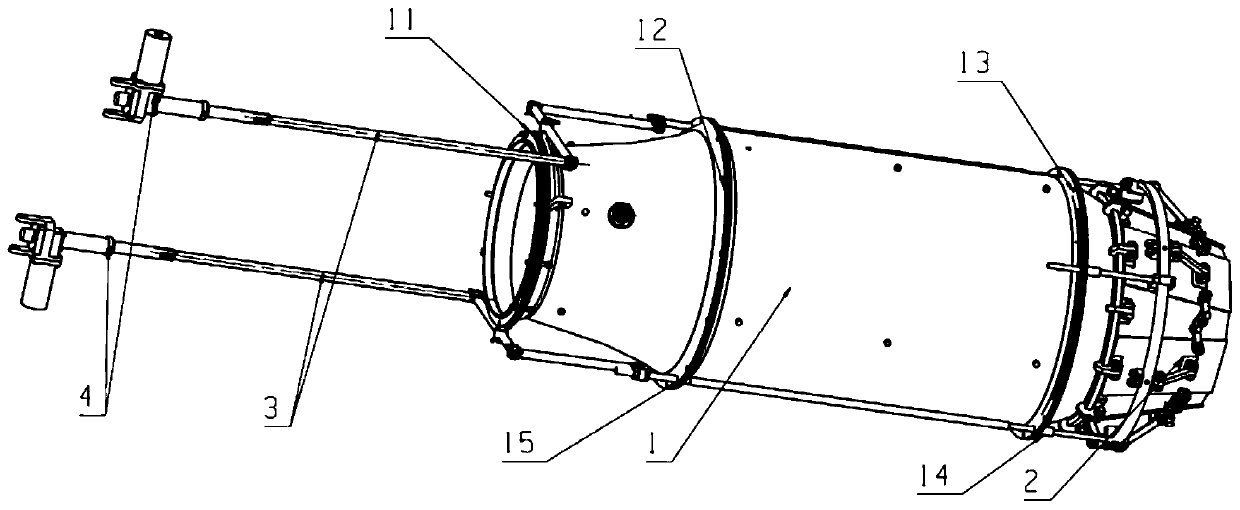

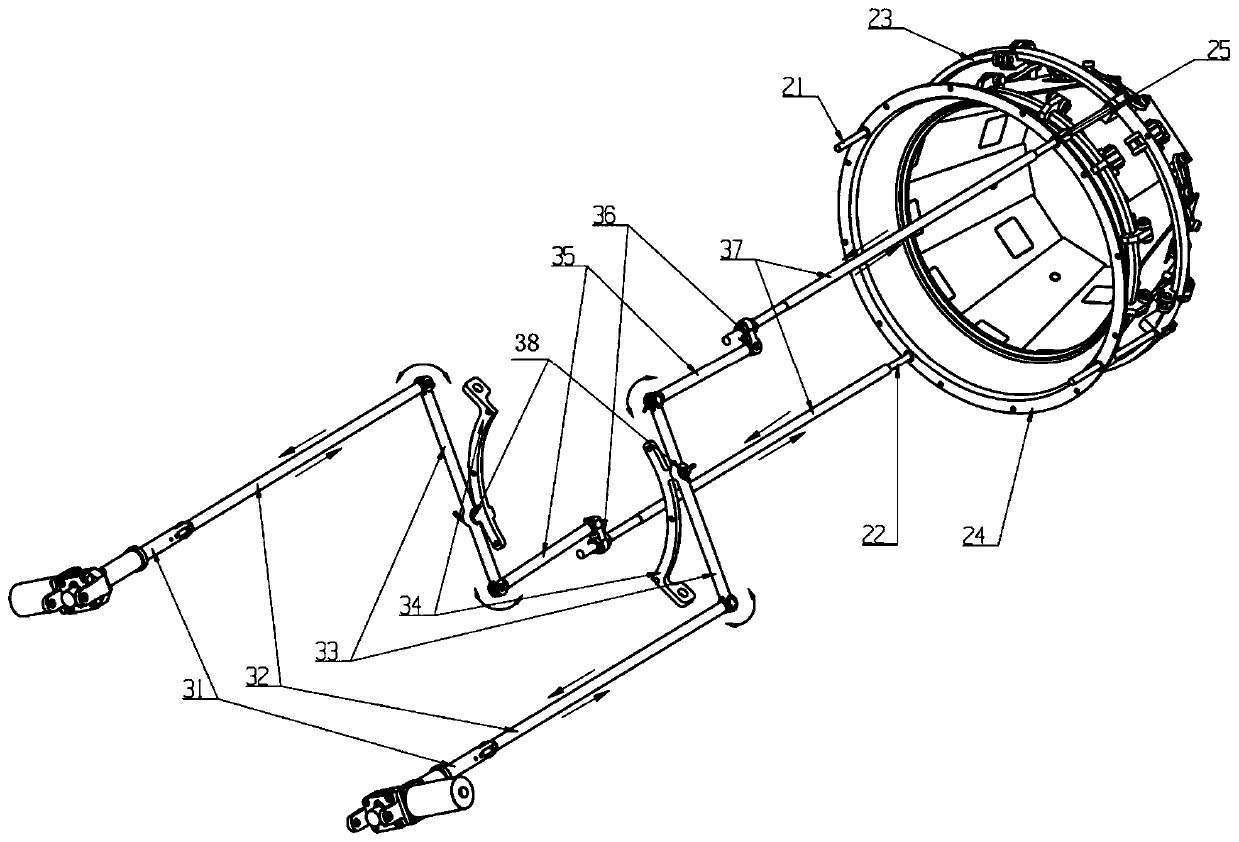

[0023] Such as figure 1 , 2 As shown, the integrated structure of the electric drive type afterburner and the adjustable area tail nozzle of the present invention is suitable for small aero turbine engines, and mainly includes the afterburner 1, the adjustable area tail nozzle 2, and the lever actuator Mechanism 3, executive electric steering gear 4 and other components. Wherein, the afterburner 1 is coaxially fixed on the rear end flange surface of the turbine engine (not shown in the figure) through its front end flange surface 11, and the adjustable area tail nozzle 2 is fixed on the rear end flange surface of the turbine engine (not shown in the figure) through its front end flange surface 24 Coaxially fixed on the rear end flange surface 13 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com