Mold device for producing horn disc body and production method applying mold device

A technology of basin and horn, which is applied to manufacturing tools, material forming presses, presses, etc., can solve the problems of poor forming quality of horn basin, lower manufacturing efficiency of horn basin, lower qualification rate of horn basin, etc. , to reduce the difficulty of operation and labor intensity, shorten the time of operation, and improve the stability and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

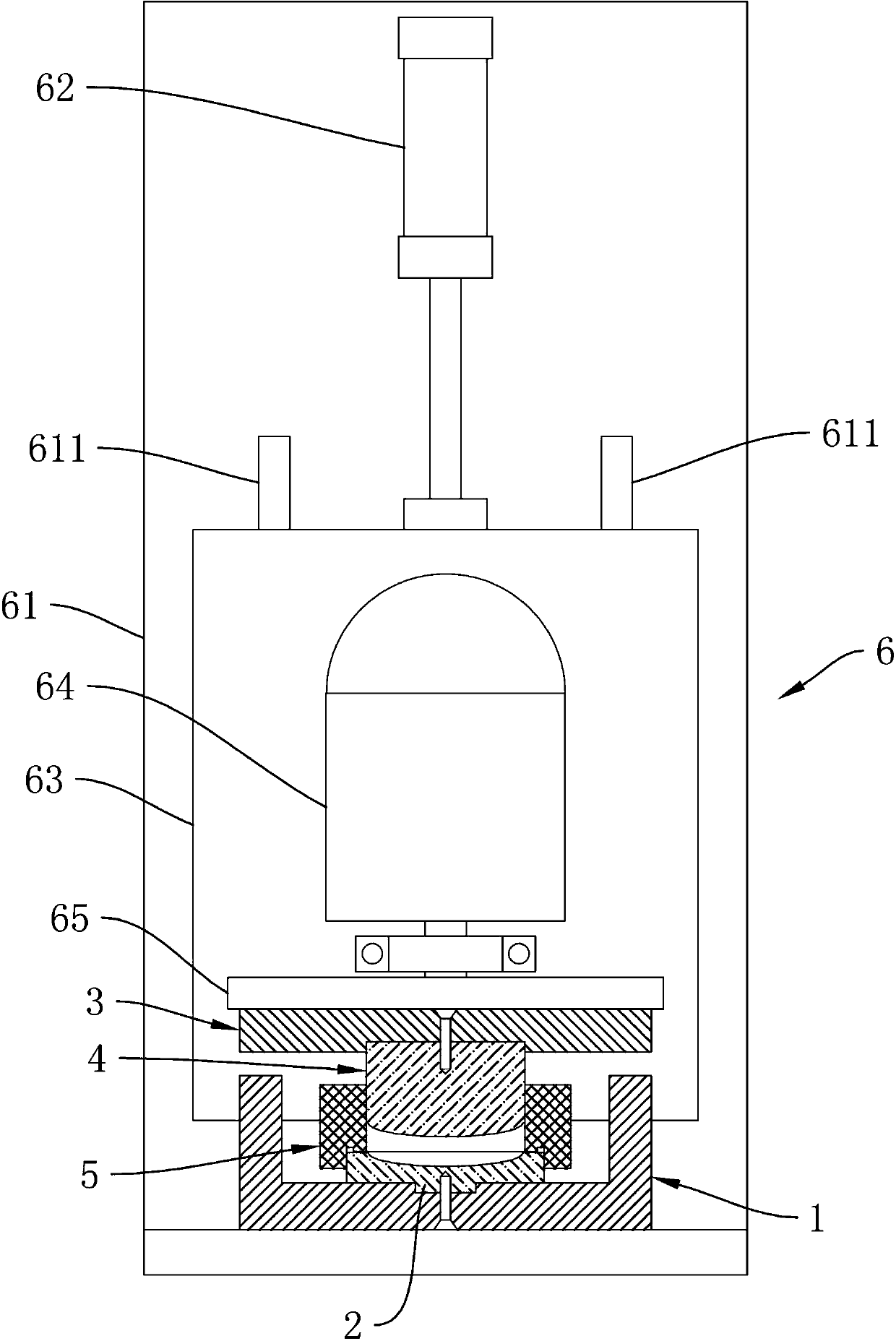

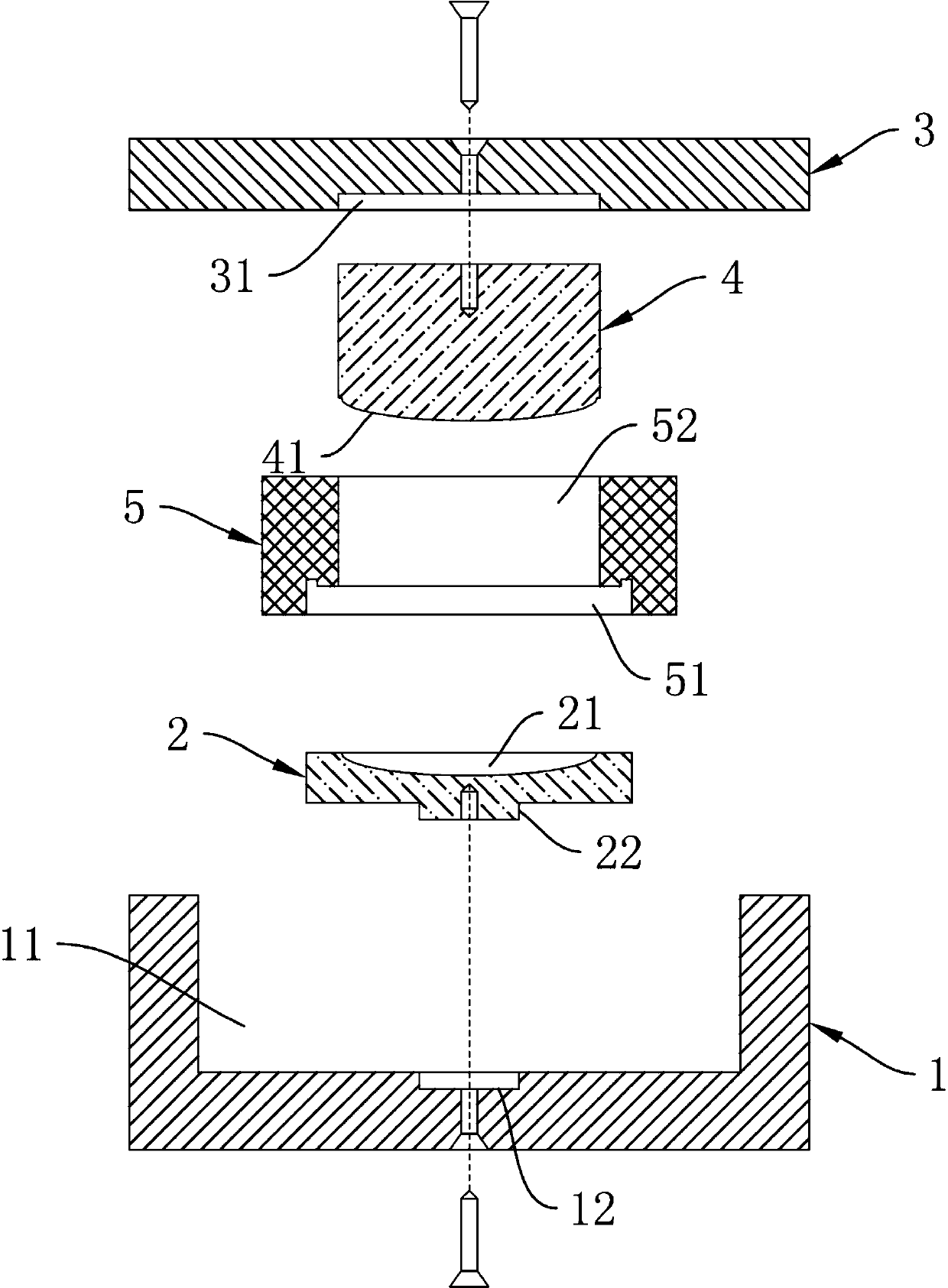

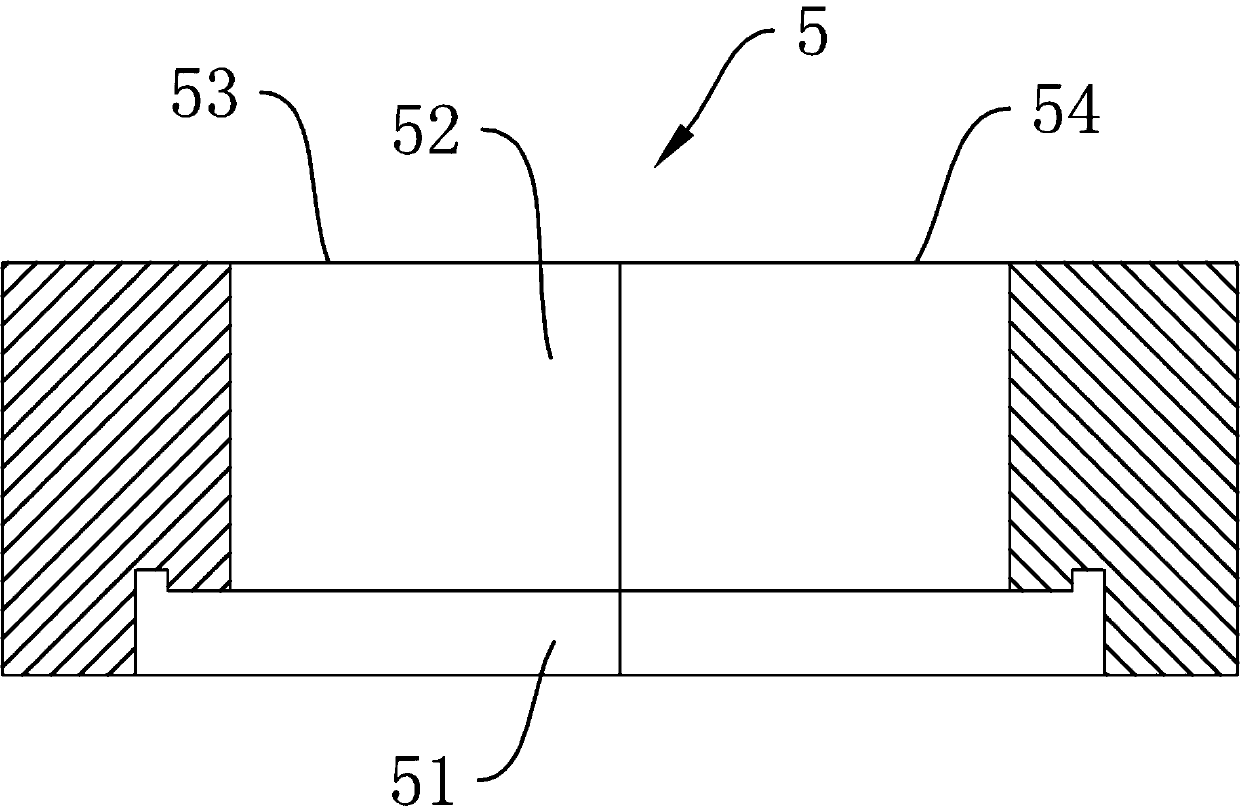

[0024] like figure 1 and figure 2As shown, a mold device for producing a horn basin according to the present invention includes a lower mold base 1, a lower mold core 2, an upper mold base 3, an upper mold core 4, a positioning mold sleeve 5, and a driving mechanism 6, wherein the lower mold base The top surface of the mold base 1 is provided with an installation cavity 11, and the bottom of the installation cavity 11 is provided with a first positioning groove 12; the top surface of the lower mold core 2 is provided with a molding groove 21, and the lower mold The bottom surface of the core 2 is provided with a positioning protrusion 22; the bottom surface of the upper mold base 3 is provided with a second positioning groove 31; the upper mold core 4 is a cylindrical structure, and one end of the upper mold core 4 is provided with a The molding groove 21 is matched with the forming convex part 41; the bottom surface of the positioning mold cover 5 is provided with a positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com