Sample preparation method for testing mechanical properties of high-thermal-conductivity mesophase pitch-based carbon fiber composite materials

A technology of mesophase pitch and composite materials, which is used in the preparation of test samples, analysis of materials, and the use of stable tension/pressure to test the strength of materials. Slip and other problems to achieve the effect of increasing the contact area and friction, improving accuracy and ensuring full play

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A sample preparation method for testing the mechanical properties of a high thermal conductivity mesophase pitch-based carbon fiber composite material, the method is used to test the mechanical properties of a high thermal conductivity mesophase pitch based carbon fiber composite flat plate sample;

[0037] Include the following steps:

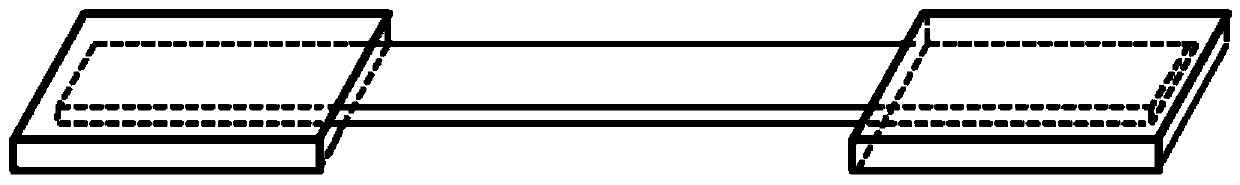

[0038] (1) According to GB / T1447-2005, a high thermal conductivity mesophase pitch-based carbon fiber reinforced resin-based composite flat sample is prepared, and the size of the sample is 230mm×12.5mm×2mm.

[0039] (2) Prepare tooling and prepare J22 resin glue;

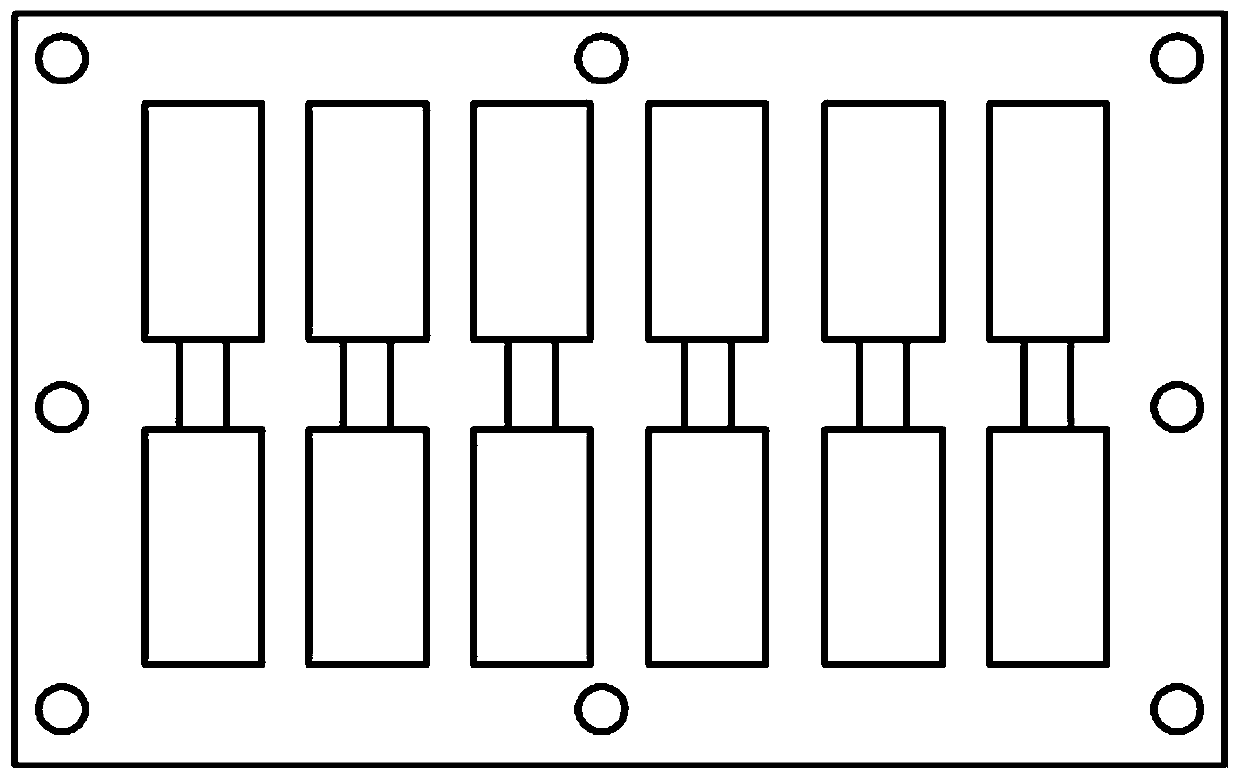

[0040] The tooling includes a bottom plate and a cover plate. The bottom plate is a steel plate with six groups of curing grooves, each group of curing grooves includes two grooves and a limiting groove, the limiting groove is located between the two grooves, The limit groove and the two grooves are coaxial, and the limit groove is used to hold the flat sample; the size of ...

Embodiment 2

[0047] (1) According to GB / T3856-2005, a high thermal conductivity mesophase pitch-based carbon fiber-reinforced resin-based composite flat sample was prepared, and the size of the sample was 140mm×6mm×2mm.

[0048] (2) Prepare tooling and prepare 618 resin glue;

[0049] The tooling includes a bottom plate and a cover plate. The bottom plate is a steel plate with six groups of curing grooves, each group of curing grooves includes two grooves and a limiting groove, the limiting groove is located between the two grooves, The limit groove and the two grooves are coaxial, and the limit groove is used to hold the flat sample; the size of the limit groove matches the size of the flat sample;

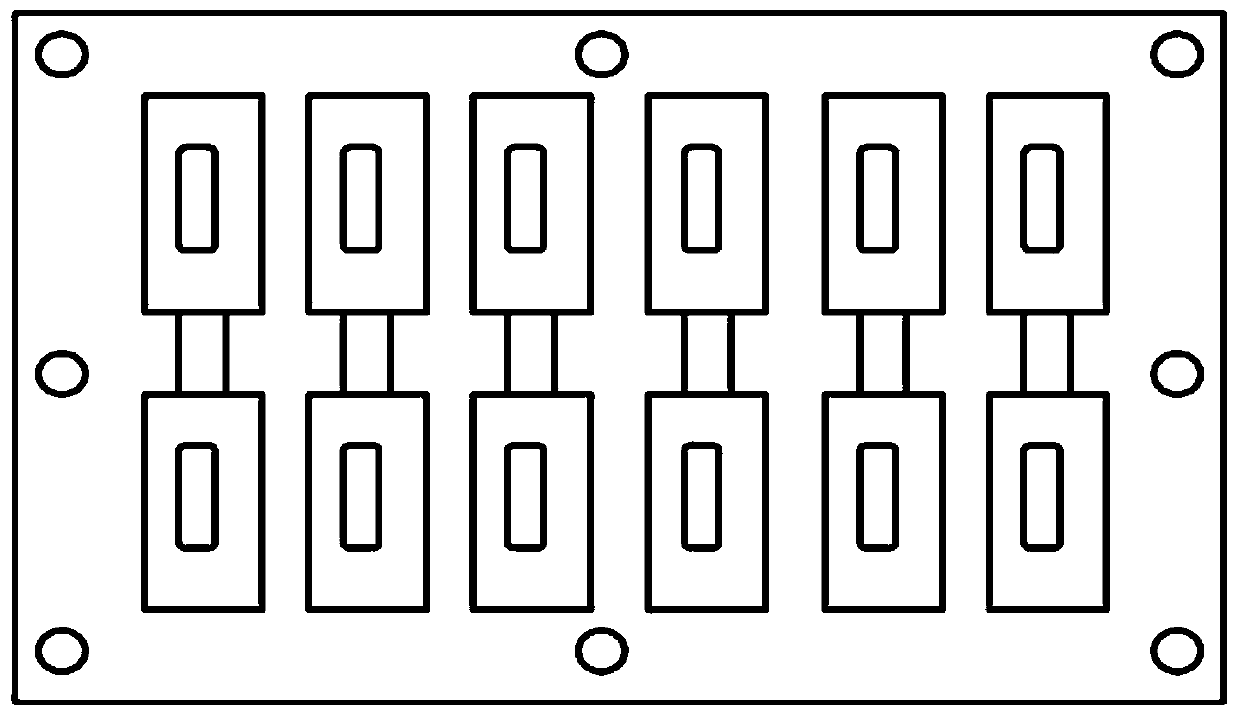

[0050] The cover plate is a steel plate with twelve injection holes;

[0051] The grooves on the base plate correspond to the glue injection holes on the cover plate;

[0052] (3) The middle part of the flat sample sample prepared in step (1) is installed in the limiting groove of the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com