Counterweighting and unloading automatic adjusting system for closure section construction and construction adjusting method thereof

A technology of automatic adjustment and closing section, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of large unloading error of counterweight, affecting the construction quality of closing section, achieve good applicability, eliminate adverse human factors, Economically significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] For a better understanding of the present invention, the following examples are further descriptions of the present invention, but the content of the present invention is not limited to the following examples.

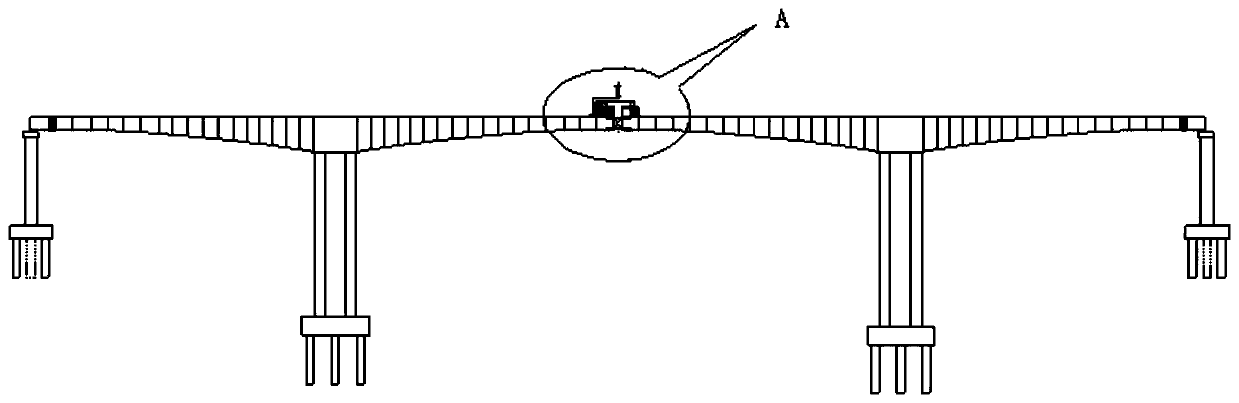

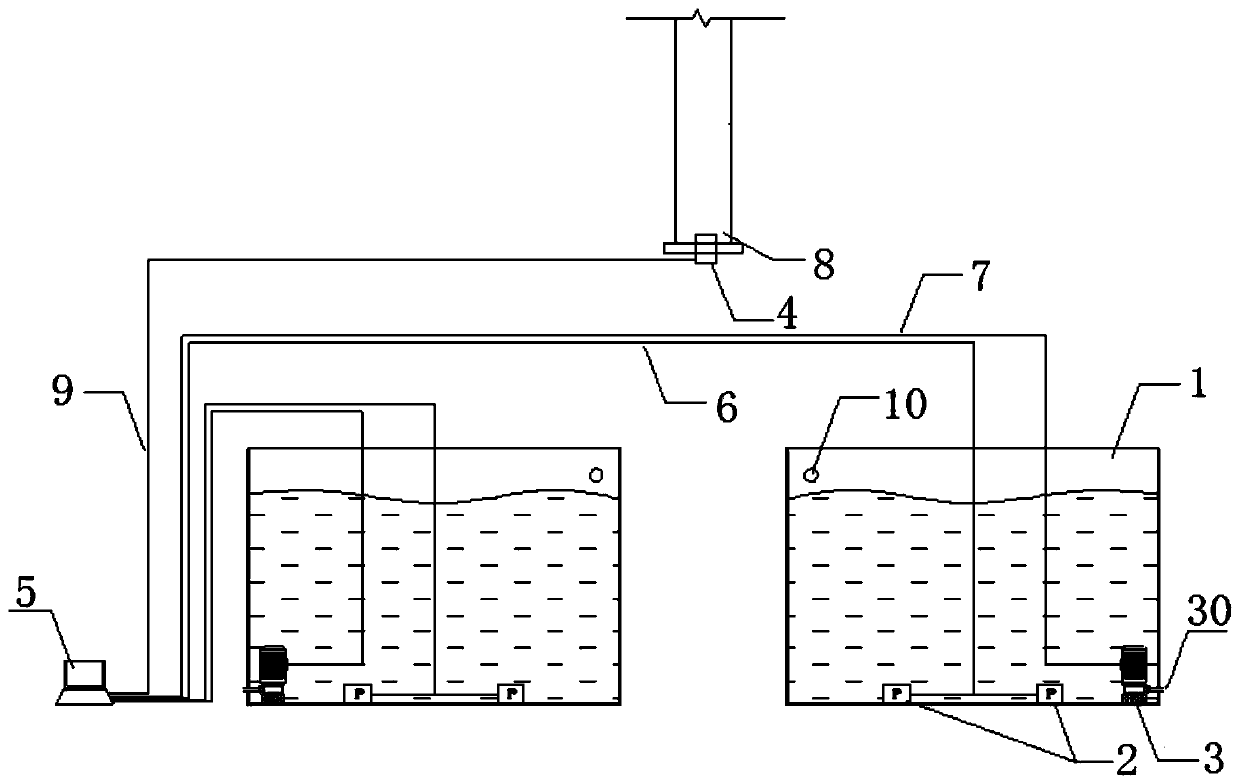

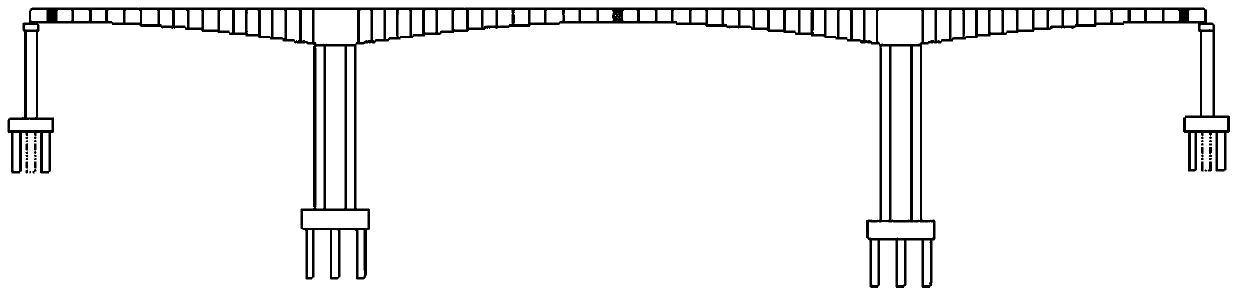

[0031] In view of the large counterweight unloading error at the construction site of the closing section, which seriously affects the construction quality of the closing section, the present invention provides an automatic adjustment system for counterweight unloading in the construction of the closing section, such as figure 1 and figure 2 As shown, the system includes a plurality of counterweight water tanks 1 , a plurality of pressure sensors 2 , two water pumps 3 , a flow rate measuring instrument 4 and a control device 5 . A plurality of counterweight water tanks 1 are symmetrically arranged on both sides of the closing section and the total weight of the counterweight water tanks 1 arranged on one side of the closing section is equal to half of the total...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com