Multi-discharge-coil automatic connecting and feeding device

A technology of feeding device and roll, which is applied in the direction of thin material processing, coiling, transportation and packaging, etc. It can solve the problems of frequent manual material change, increase of production cost, waste of production time, etc., so as to avoid rewinding The effect of discharging materials, saving production costs and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with specific embodiment and accompanying drawing, the present invention is further elaborated and illustrated:

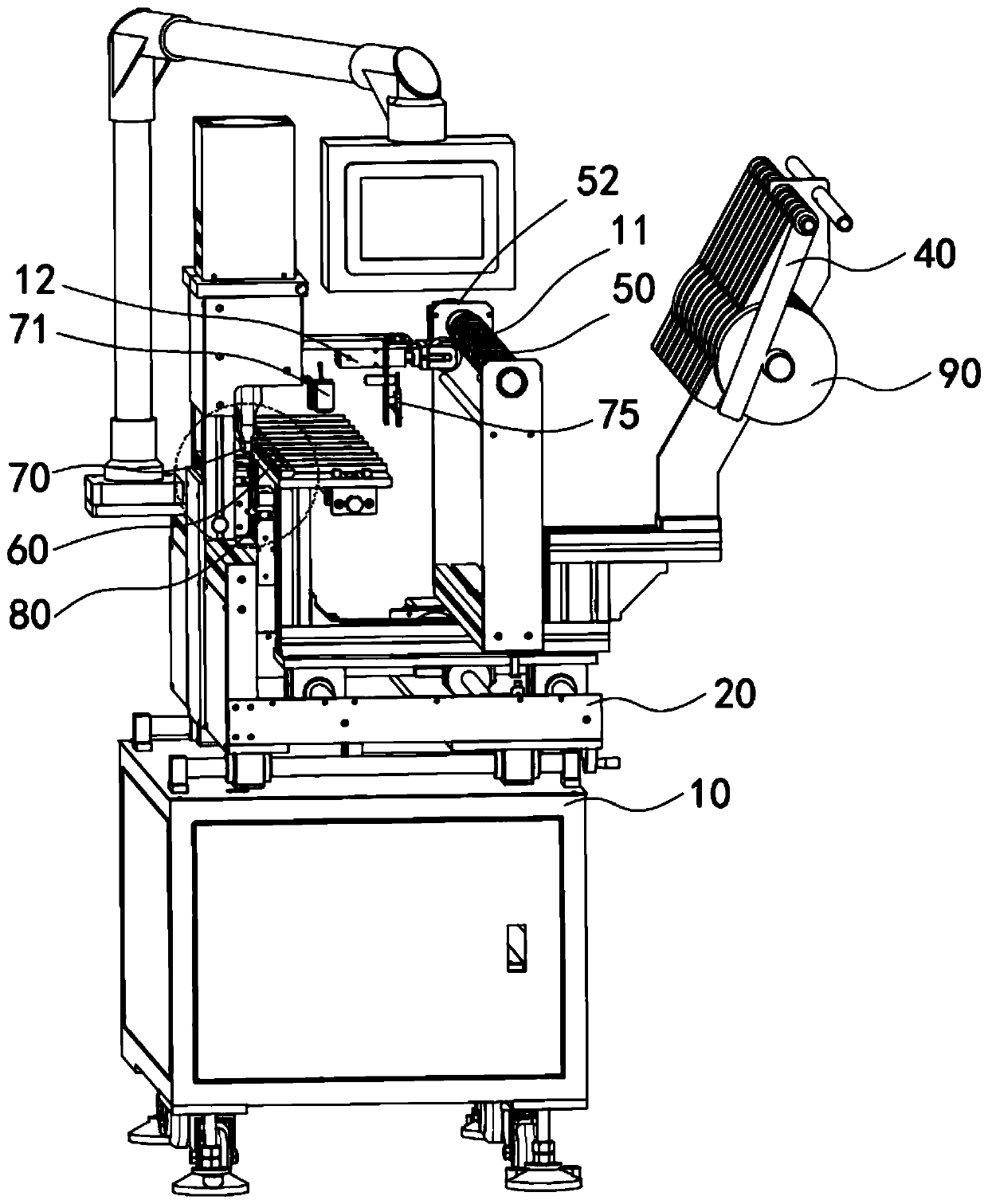

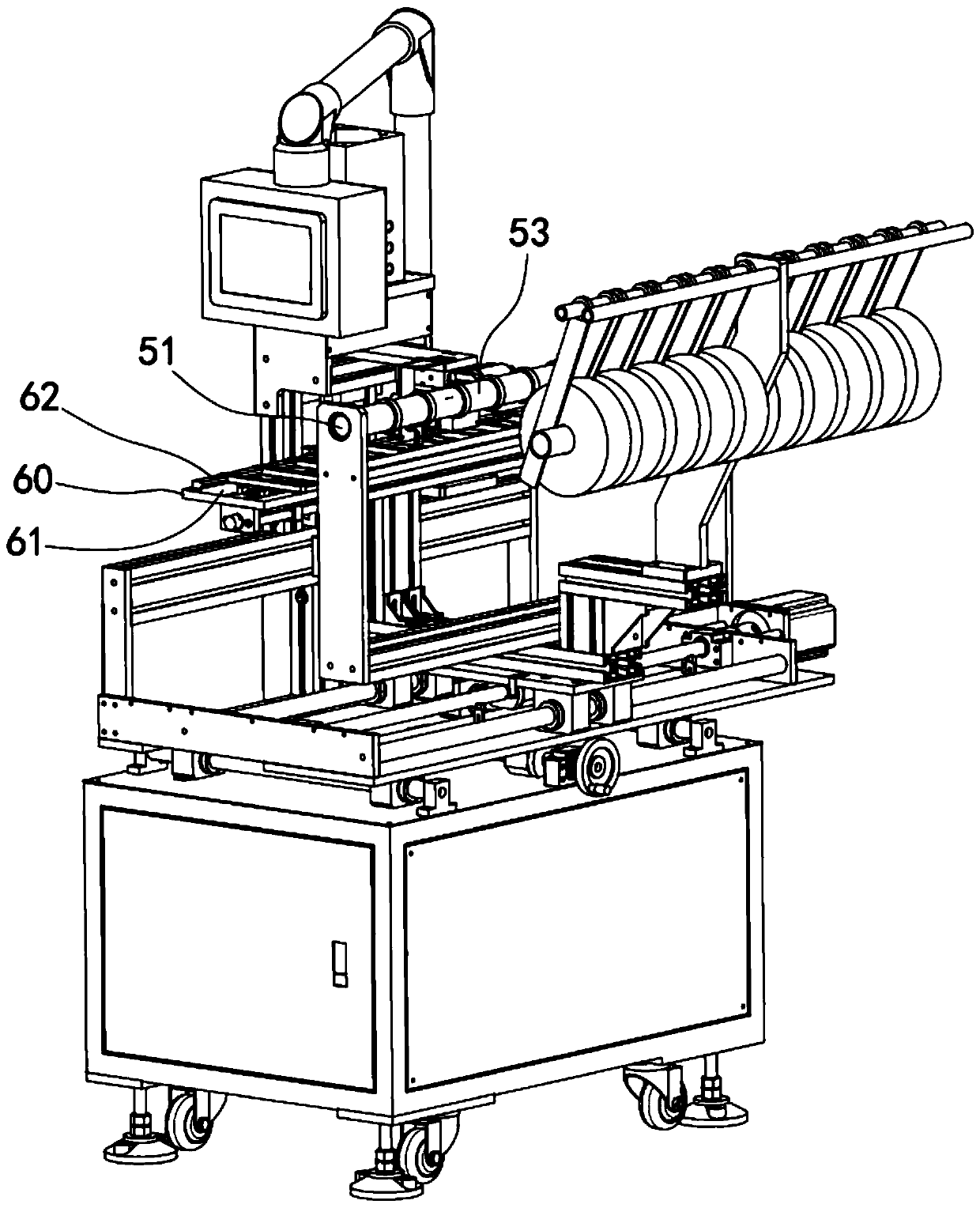

[0022] Please refer to figure 1 , a multi-row material roll automatic connection feeding device, used to feed the front-end process equipment, including a fixed bracket 10, a sliding bracket 20, a drive assembly 30 and a control device, the sliding bracket 20 is located on the fixed bracket 10, and can be used in Driven by the driving assembly 30 , it slides relative to the fixed bracket 10 .

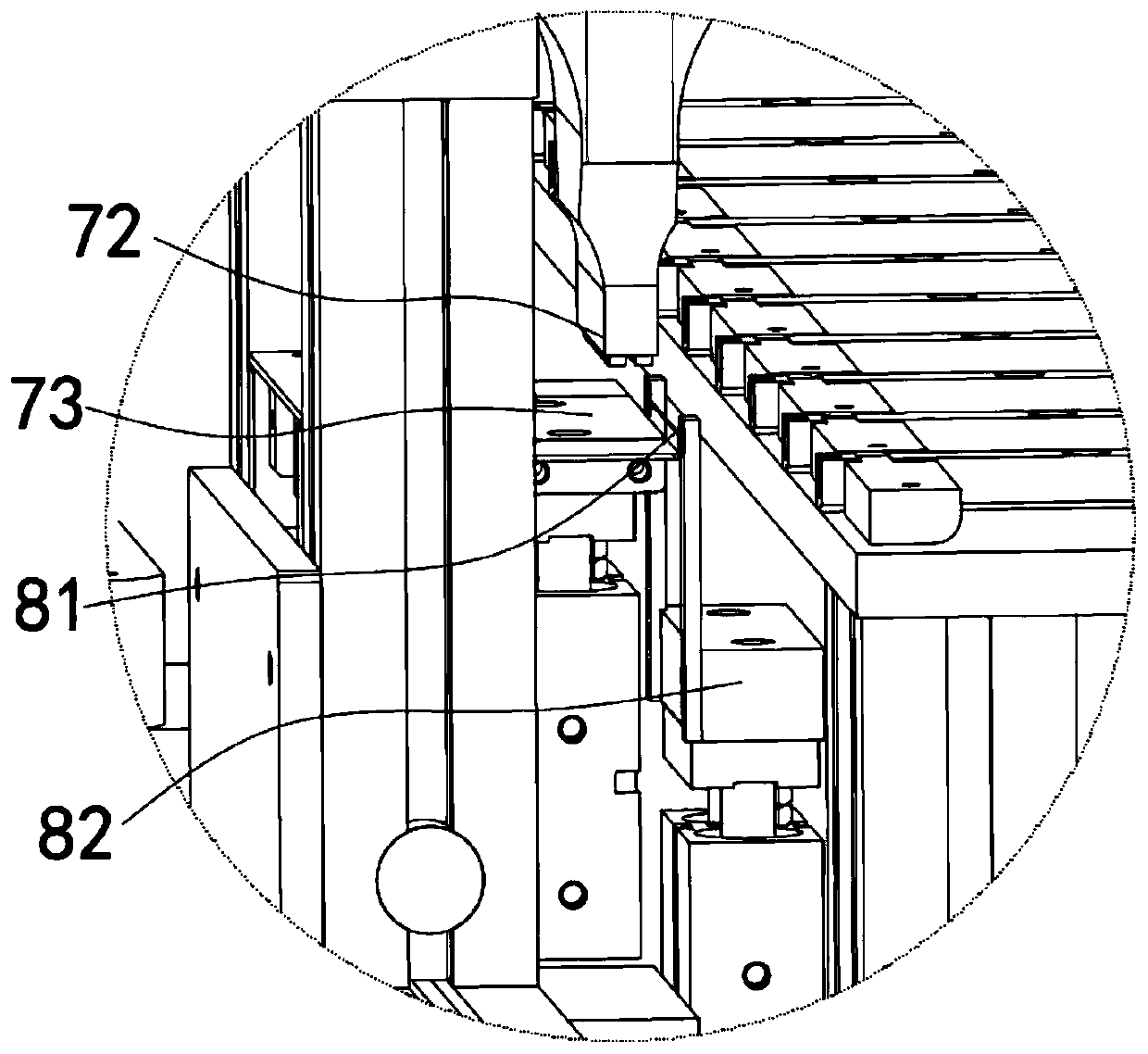

[0023] The sliding support 20 is provided with a feeding assembly 40, a feeding assembly 50 and a material guide plate 60 for storing several material rolls 90, and several material rolls 90 stored in the discharging assembly 40 all pass through the feeding assembly 50 and the material guide plate 60 in turn. , when working, the material tape unfolded by the material roll 90 is pulled by the front-end process equipment, and at the same time, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com