Electrolyte formula powder and preparation method thereof

A formula powder and electrolyte technology, applied in food science and other directions, can solve the problems of patients with low nutritional value, inability to solve electrolyte imbalance, electrolyte imbalance, etc., to shorten hospital stay, facilitate physical recovery, and reduce insulin resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

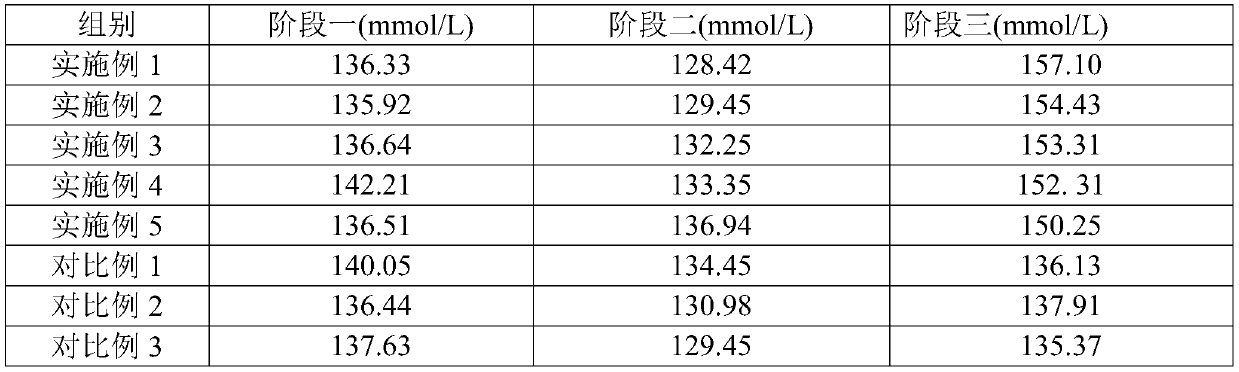

Examples

Embodiment 1

[0022] An electrolyte compound powder comprises: 21 g of maltodextrin, 4 g of crystalline fructose, 0.23 g of edible salt, 0.28 g of dipotassium hydrogen phosphate, 0.07 g of magnesium sulfate, 0.2 g of citric acid, and 0.001 g of sucralose.

[0023] The preparation method of above-mentioned electrolyte formula powder comprises the following steps:

[0024] (1) each raw material is pulverized and sieved to 80 meshes, and then mixed uniformly to obtain a mixture;

[0025] (2) packing the mixture prepared in step (1).

Embodiment 2

[0027] An electrolyte compound powder comprises: 10 g of maltodextrin, 2 g of crystalline fructose, 0.1 g of edible salt, 0.2 g of dipotassium hydrogen phosphate, 0.05 g of magnesium sulfate, 0.1 g of citric acid, and 0.02 g of sucralose.

[0028] The preparation method of above-mentioned electrolyte formula powder comprises the following steps:

[0029] (1) each raw material is pulverized and sieved to 80 meshes, and then mixed uniformly to obtain a mixture;

[0030] (2) packing the mixture prepared in step (1).

Embodiment 3

[0032] An electrolyte compound formula powder comprises: 12 g of maltodextrin, 4 g of crystalline fructose, 0.3 g of edible salt, 0.3 g of dipotassium hydrogen phosphate, 0.08 g of magnesium sulfate, 0.2 g of citric acid, and 0.02 g of sucralose.

[0033] The preparation method of above-mentioned electrolyte formula powder comprises the following steps:

[0034] (1) each raw material is pulverized and sieved to 80 meshes, and then mixed uniformly to obtain a mixture;

[0035] (2) packing the mixture prepared in step (1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com