Aerosol-generating article having fibrous filter segment

An aerosol generation and aerosol technology, which is applied in the fields of e-liquid filter elements, smoker supplies, textiles and papermaking, etc., can solve the problems of complicated or expensive manufacturing of aerosol cooling elements, and achieve the effect of eliminating the need and reducing the number of manufacturing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

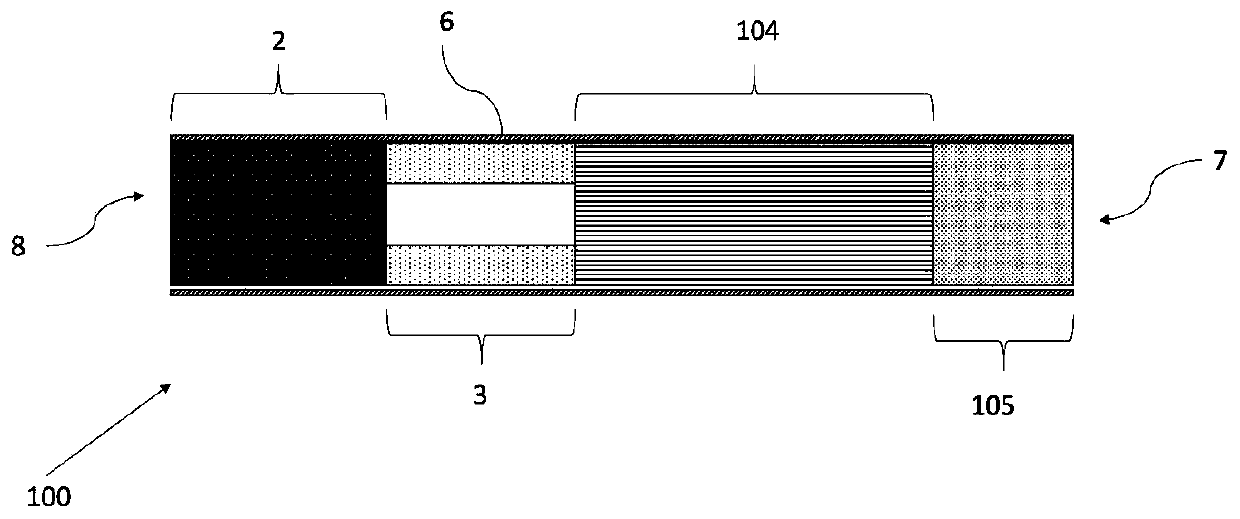

[0082] figure 1 A prior art aerosol-generating article 100 is illustrated. Article 1 comprises four elements. The elements are: an aerosol generating substrate 2, a support element 3, an aerosol cooling element 104 and a filter segment 105 comprising cellulose acetate fibers having a denier per filament of about 8.

[0083] These four elements are arranged one behind the other and in coaxial alignment and are assembled from the rolling paper 6 to form a rod. The strip has a mouth end 7 which the user inserts into his or her mouth during use and a distal end 8 which is located at the end of the strip opposite the mouth end 7 . Elements located between the oral end 7 and the distal end 8 may be described as being upstream of the oral end 7 , or alternatively downstream of the distal end 8 . When assembled, the bar had a length of 52 mm and a diameter of 7.2 mm. The filter segment 105 has a length of 8 mm and the aerosol cooling element 104 has a length of 17 mm.

[0084] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com