High-reliable electric heating pipe sealing structure and method

A technology of sealing structure and electric heating pipe, applied in the direction of ohmic resistance waterproof/airtight, ohmic resistance heating parts, heating element shape, etc. between 4' of sealant, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

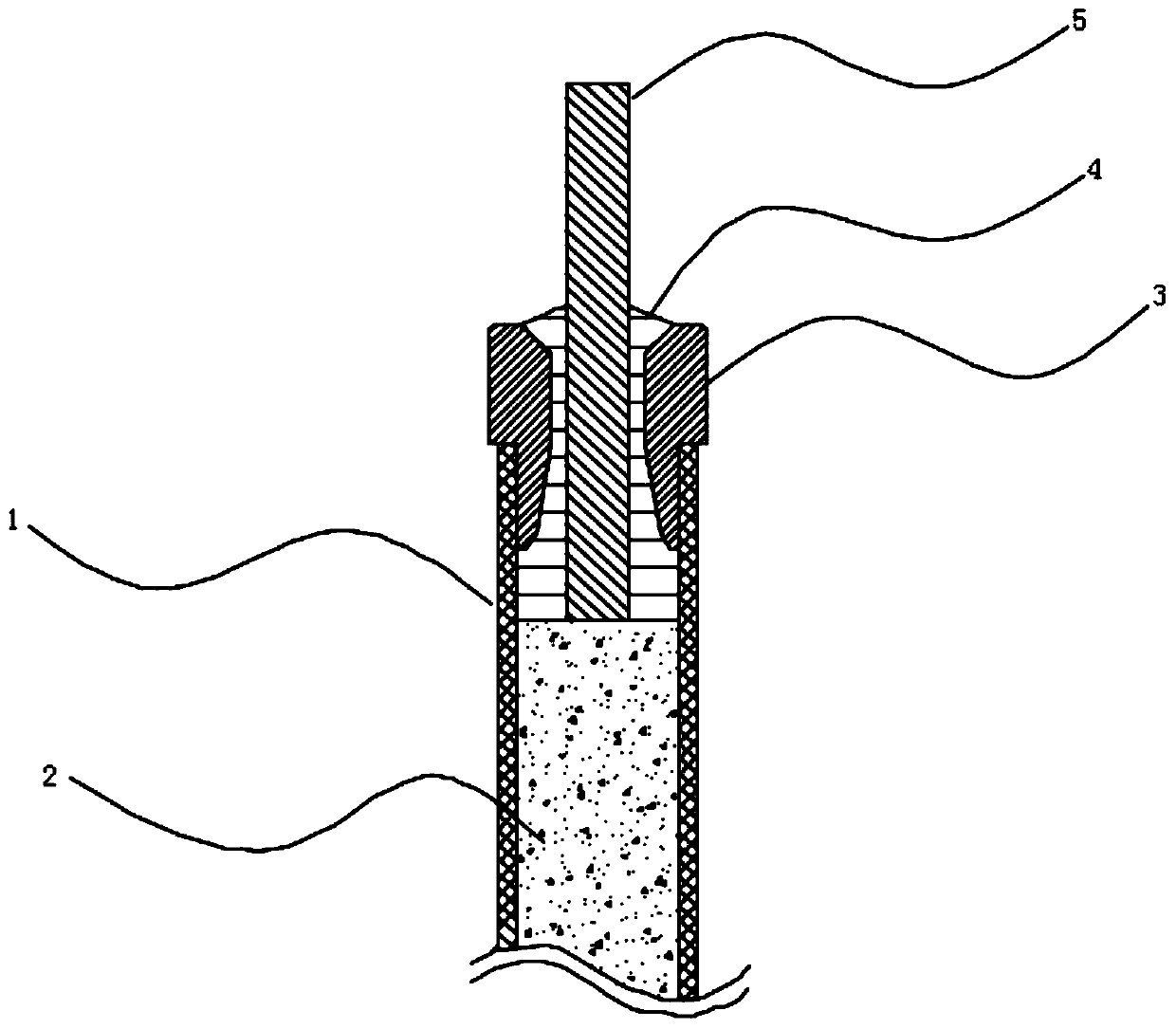

[0027] see Figure 2-Figure 3 On the one hand, the present invention provides a high-reliability electric heating tube sealing structure, including an electric heating tube body 1, a lead rod 5 is provided in the electric heating tube 1 body, and magnesium oxide powder is filled between the lead rod 5 and the electric heating tube body 1 2. An insulating sealing device 3 is provided at the sealing part of the electric heating pipe body 1, and the insulating sealing device 3 includes a sealing body, the upper end of the sealing body is provided with an upper opening 31, and the lower end of the sealing body is provided with a lower opening 33, and the upper opening 31 and the lower opening 33 is provided with a through middle channel 32, the outer wall of the sealing body is provided with a step portion 34, the guide rod 5 runs through the middle channel 32 of the insulating sealing device 3, the middle channel There is a gap between 32 and the guide rod 5, a sealant 4 is provi...

Embodiment 2

[0034] Such as Figure 3-4 As shown, the difference between Embodiment 2 and Embodiment 1 lies in that the structure of the middle channel is different, and other structures are the same.

[0035] In this embodiment, the middle passage 32 includes a first middle passage 321 and a lower passage 322 sequentially along the upper end to the lower end of the insulating sealing device 3, the upper end of the first middle passage 321 communicates with the lower end of the upper opening 31, the first The lower end of the middle passage 321 communicates with the upper end of the lower passage 322, and the lower end of the lower passage 322 communicates with the upper end of the lower opening 33. The above arrangement divides the middle passage 32 into two parts, and the sealant entering the lower passage 322 passes through In the middle channel 32, the lead rod and the insulating sealing device are well bonded through the sealant 4, so that the insulating sealing device is closely comb...

Embodiment 3

[0037] The present invention provides a method for sealing a high-reliability electric heating tube. The sealing structure of the high-reliability electric heating tube is shown in Embodiment 1 and Embodiment 2. The sealing method includes the following steps:

[0038] 1) Fill magnesium oxide powder 2 in the electric heating tube body 1;

[0039] 2) Dig out d millimeters of magnesium oxide powder 2 at the end of the electric heating tube body 1;

[0040] 3) Pre-inject the sealant 4 into the electric heating pipe body 1, and make the injected sealant 4 be away from the nozzle of the electric heating pipe body 1 by d / 8mm; in this embodiment, d is 5-13mm, the above setting, Easy to operate;

[0041] 4) Press the insulating sealing device 3 into the sealant 4 , and the sealant 4 flows out from the gap between the middle channel 32 and the guide rod 5 toward the upper opening 31 to fill the gap between the sealing body and the guide rod 5 .

[0042] In the above method, since the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com