A method for reducing low-frequency vibration of a generator stator based on air gap characteristic values

A low-frequency vibration and eigenvalue technology, which is applied to the control of generators, the control of generators through magnetic field changes, and the protection of power generation through control, can solve problems such as stator low-frequency vibrations, reduce low-frequency vibrations of stators, and improve rotor roundness and eccentricity. Degree, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

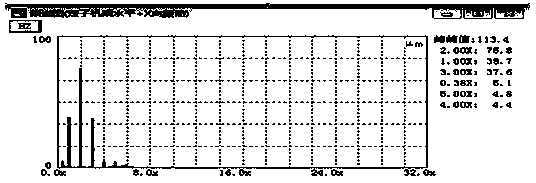

[0030] A hydroelectric generator with a capacity of 650MW, a rated speed of 125r / min, and a total of 48 magnetic poles. After the overhaul, the boost test of the generator was carried out. When the excitation current rose to the maximum, the horizontal vibration of the stator frame was 113 μm, and the vibration index did not meet the requirements. In order to reduce the low-frequency vibration of the stator, the following specific steps were taken:

[0031] (1) From the online TN8000STA monitoring system, collect the stator low-frequency vibration amplitude and spectrum data under the condition of no-load and rated excitation current, such as figure 1 :

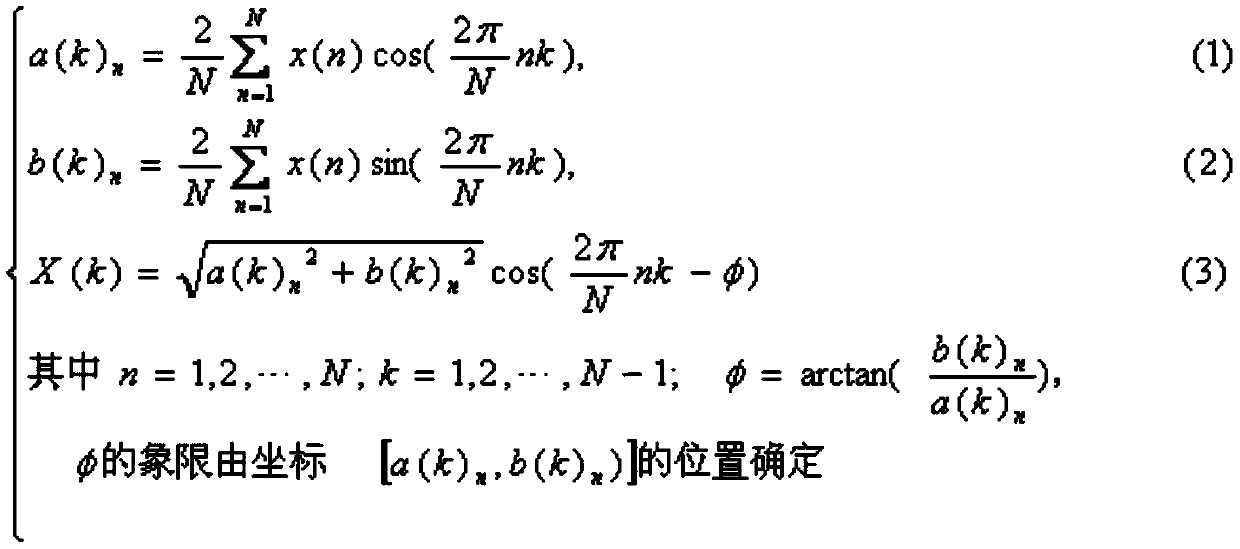

[0032] (2) From the online TN8000AGMS monitoring system, collect the generator air gap function value x(n), the unit is: mm, the collection time points are consistent with the collection time points of the stator low-frequency vibration amplitude and spectrum data, and according to the power generation For the rotation direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com