Dynamic and static submarine optical cable connector box

A submarine optical cable and splice box technology, which is applied in the directions of light guide, optics, optical components, etc., can solve the problems that the splice box cannot meet the strength requirements of submarine optical cable laying, large construction risks, and processing difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

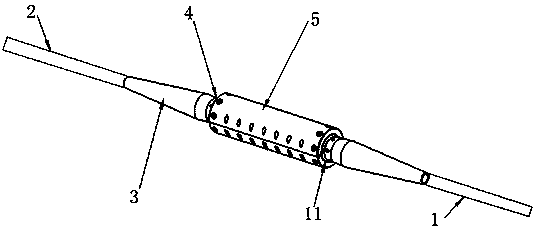

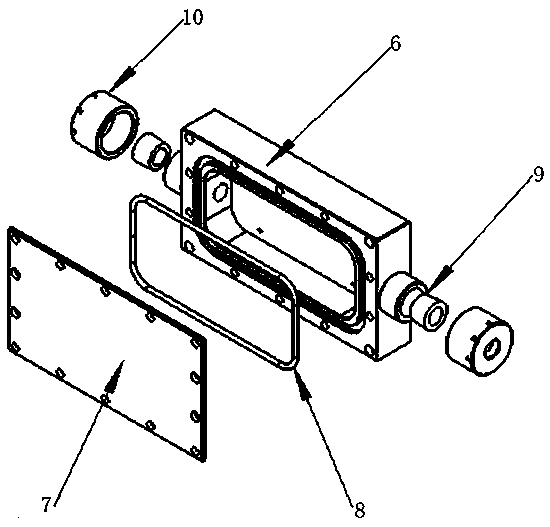

[0026] The invention is a dynamic and static submarine optical cable splice box, such as figure 1 As shown, there are anti-bending devices 3 respectively sleeved on the connection end sides of the dynamic submarine optical cable 1 and the static submarine optical cable 2 to effectively ensure the bending degree of the dynamic submarine optical cable 1 and the static submarine optical cable 2, and the end of the static submarine optical cable 2 The steel wire armor device 4 realized by two layers of armored steel wire armor is clamped and fixed on the cylinder 5, and the steel wire armor device 4 is fixed by screw locking. The dynamic submarine optical cable 1 is made of glue 11. The method reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com