Method and device for determining attitude and position of coal mining machine

A positioning method and technology for shearers, which are used in measuring devices, surveying and navigation, force/torque/work measuring instruments, etc., can solve the problem that the position of the shearer cannot be continuously monitored, it has not been effectively applied, and installation errors cannot be eliminated, etc. problems, to achieve the effect of simple and reliable structure, easy maintenance or replacement, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

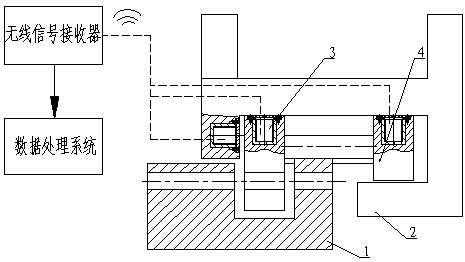

[0014] Assuming that the installation distance between the two guide shoes of the shearer is L, within the length of L, there are N pin racks (including the pin racks at both ends in contact with the guide shoes).

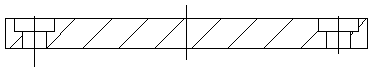

[0015] Within the entire length of the conveyor, sensor units are respectively installed on the upper surface of each pin rack, and the two sensor units are arranged symmetrically along the axis of the pin axis. The one on the side is called the right sensor unit.

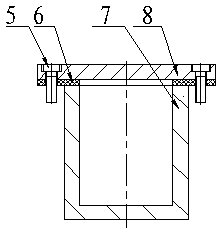

[0016] The left sensor unit and the right sensor unit are mounted on the upper surface of the pin rack. There are two grooves on the upper surface of each pin rack (that is, the upper surface of the rails on both sides of the pin rack). There are left sensor unit and right sensor unit, and the wireless pressure sensor is installed in the sensor quick changer.

[0017] There are several threaded holes on the ring-shaped surface of the two grooved step holes on the upper surface of each pin rack. The th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com