A kind of preparation method of concrete pipe with rubber ring groove

A technology of concrete pipes and rubber rings, applied in flange connection, mechanical equipment, pipes/pipe joints/pipe fittings, etc., can solve the problems of difficult interface installation, shape deformation, excessive size of sockets, etc., and achieve the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following examples illustrate the practicability of the technical solutions of the present invention, but should not limit the protection scope of the present invention to the following specific examples.

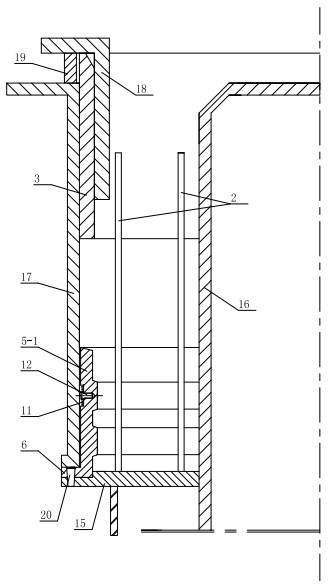

[0019] The concrete pipe to be prepared by the present invention is as Figure 4 As shown, including the pipe body 1, the pipe body 1 is embedded with a steel skeleton 2, one end of the pipe body is a socket, and the socket is formed by a socket steel sleeve 3 integrally connected with the pipe body, and the other end of the pipe body For the socket, the outer wall of the socket is provided with an apron groove 4.

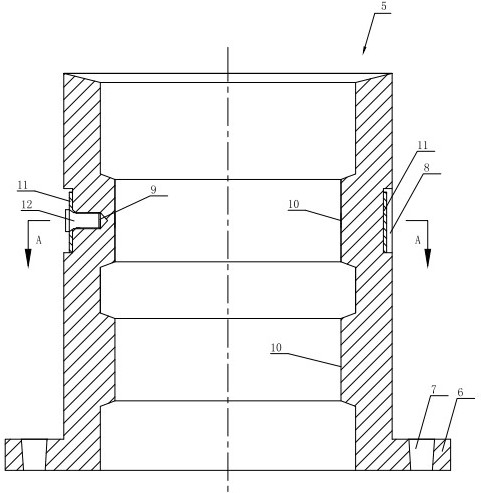

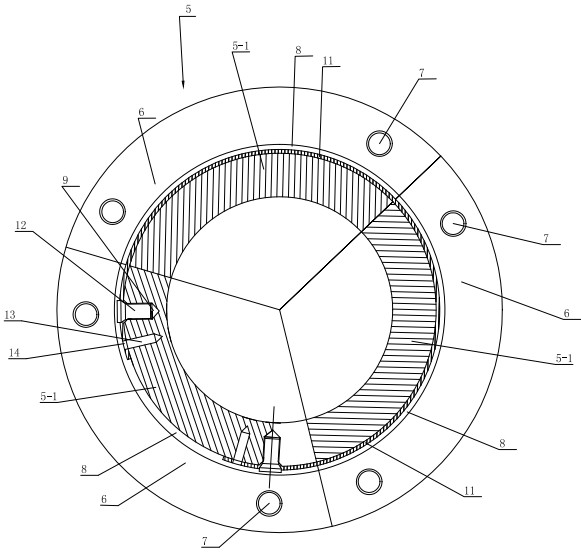

[0020] The spigot forming ring involved in the present invention is as figure 2 and image 3 As shown, the socket forming ring body 5 is included, and the socket forming ring body 5 includes a plurality of arc-shaped ring petals 5-1, three ring petals 5-1 are shown in the figure, of course, it can also be set as four , the bottom of the outer wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com