Post-tensioning self-resetting joints capable of multi-stage energy dissipation and assembling method for post-tensioning self-resetting joints

A post-tensioning, multi-stage technology, applied in the direction of building types, buildings, building components, etc., can solve the problems of large inter-story displacement and inter-story acceleration, low initial stiffness of SMA nodes, and sharp decrease of node rotational stiffness. Achieve the effect of clear design concept, maintenance-free and high node performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

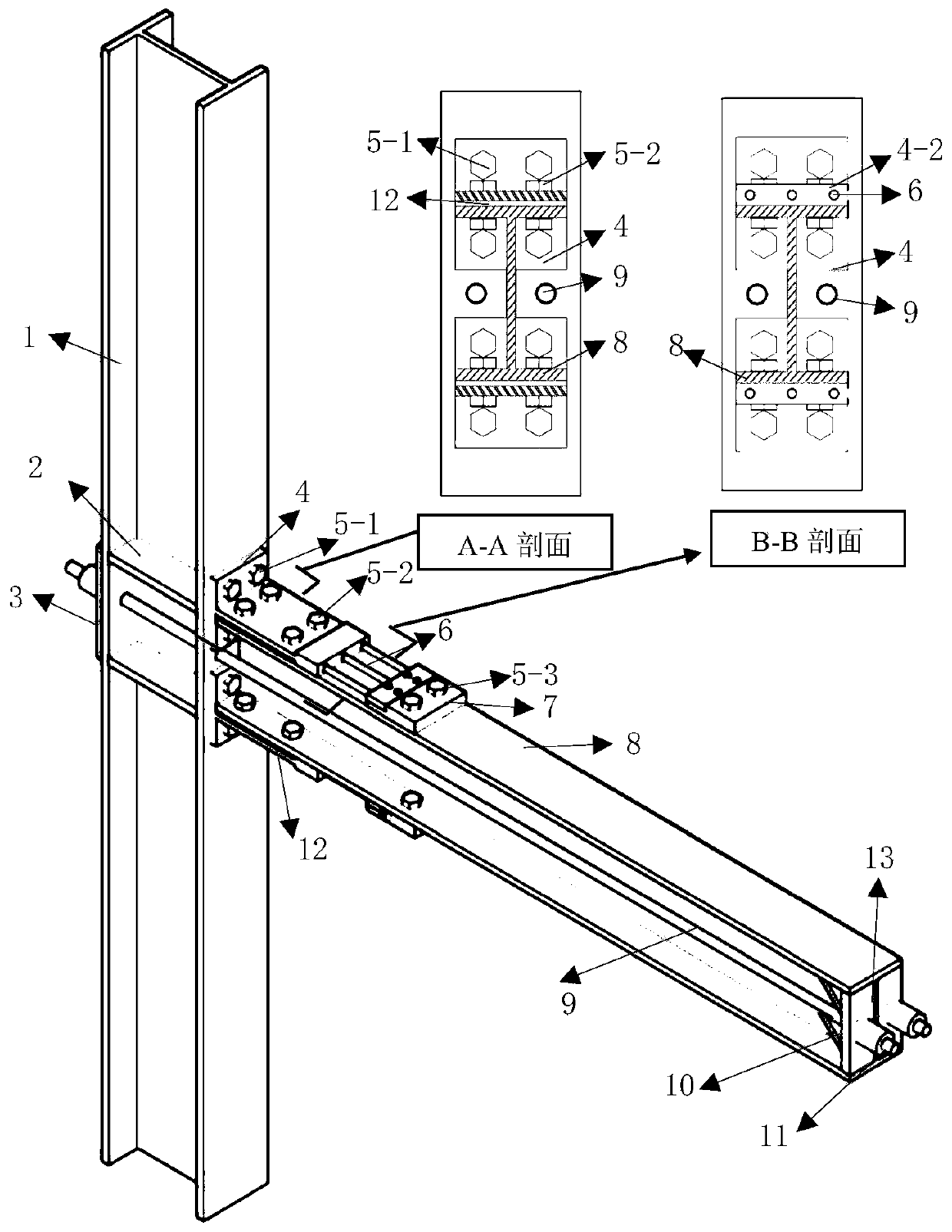

[0040] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, a detailed description will be given below in conjunction with the accompanying drawings and specific implementation examples.

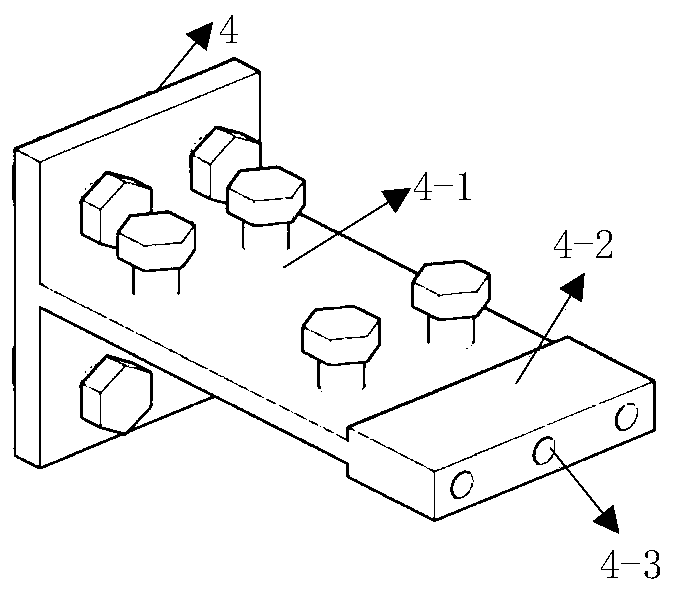

[0041] The present invention proposes a post-tensioning self-resetting node based on SMA damping device and frictional multi-stage energy consumption, including: 1. I-shaped steel column, 2. I-shaped steel beam, 3. T-shaped connector with enlarged end , 4. SMA bar damper, 5. Prestressed steel rod, 6. Anchorage, 7. Reinforced version of the anchorage of the outer flange of the column, 8. Column transverse stiffener, 9. Beam anchorage end plate and end stiffener, 10 11. Frictional high-strength bolts.

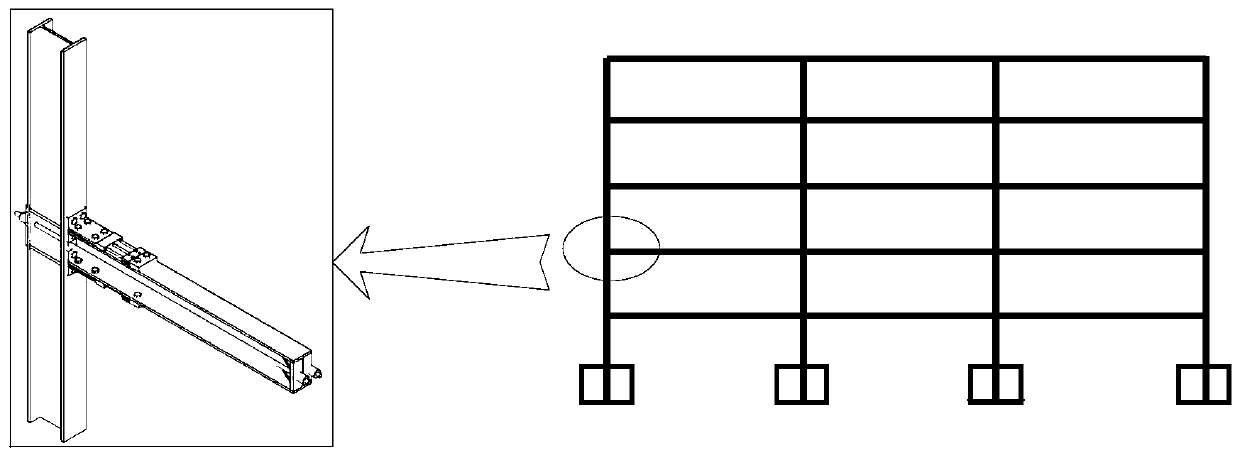

[0042] This self-resetting node is taken from the beam-column node selected in the structure, which includes the above-mentioned structural components, the reinforcement plate at the anchorage of the column is welded on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com