Quick support formwork for pipe gallery and construction method thereof

A formwork, rapid technology, applied in artificial islands, water conservancy projects, infrastructure engineering, etc., to achieve the effect of simplifying the construction process, reducing construction links, and simplifying the internal support structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

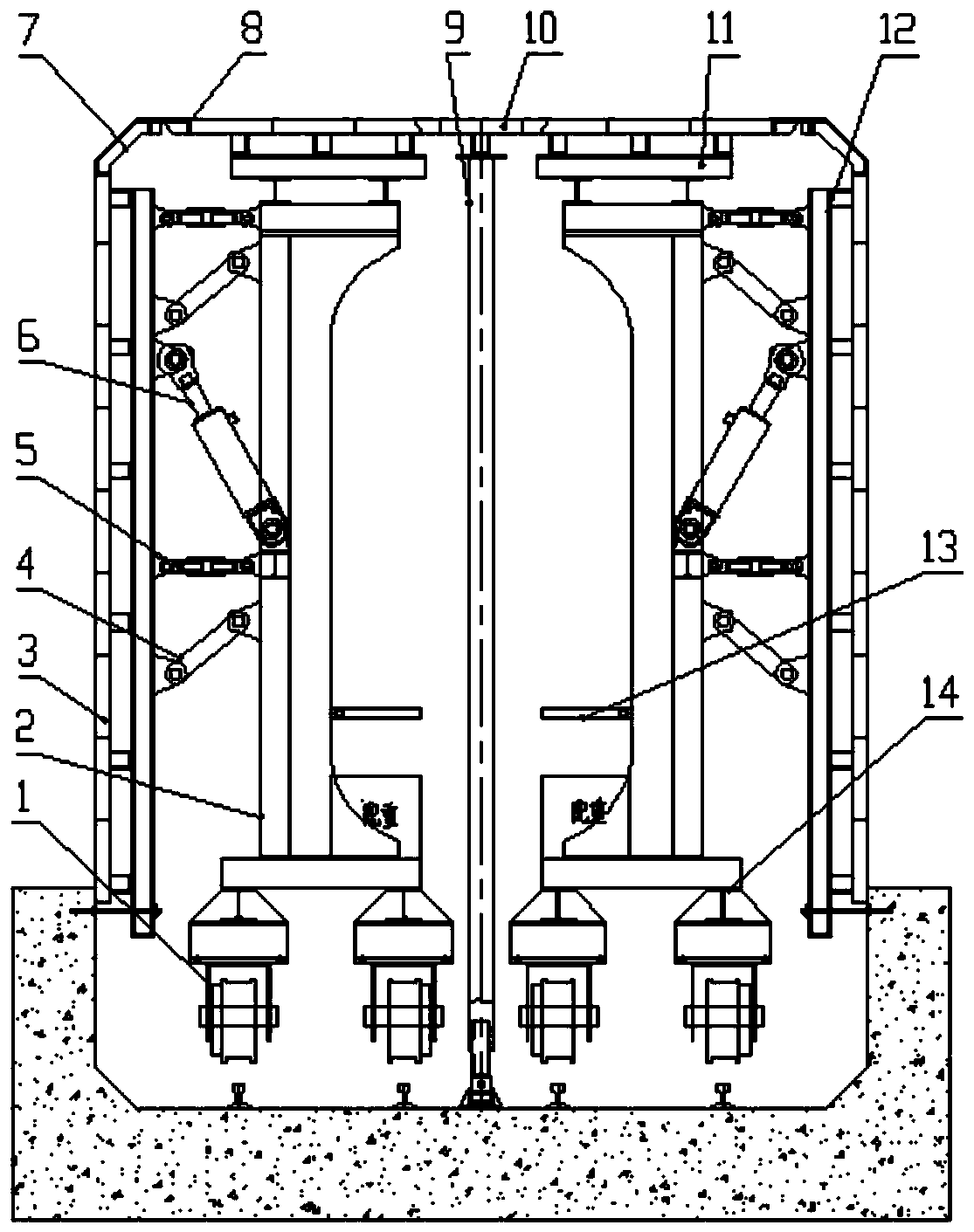

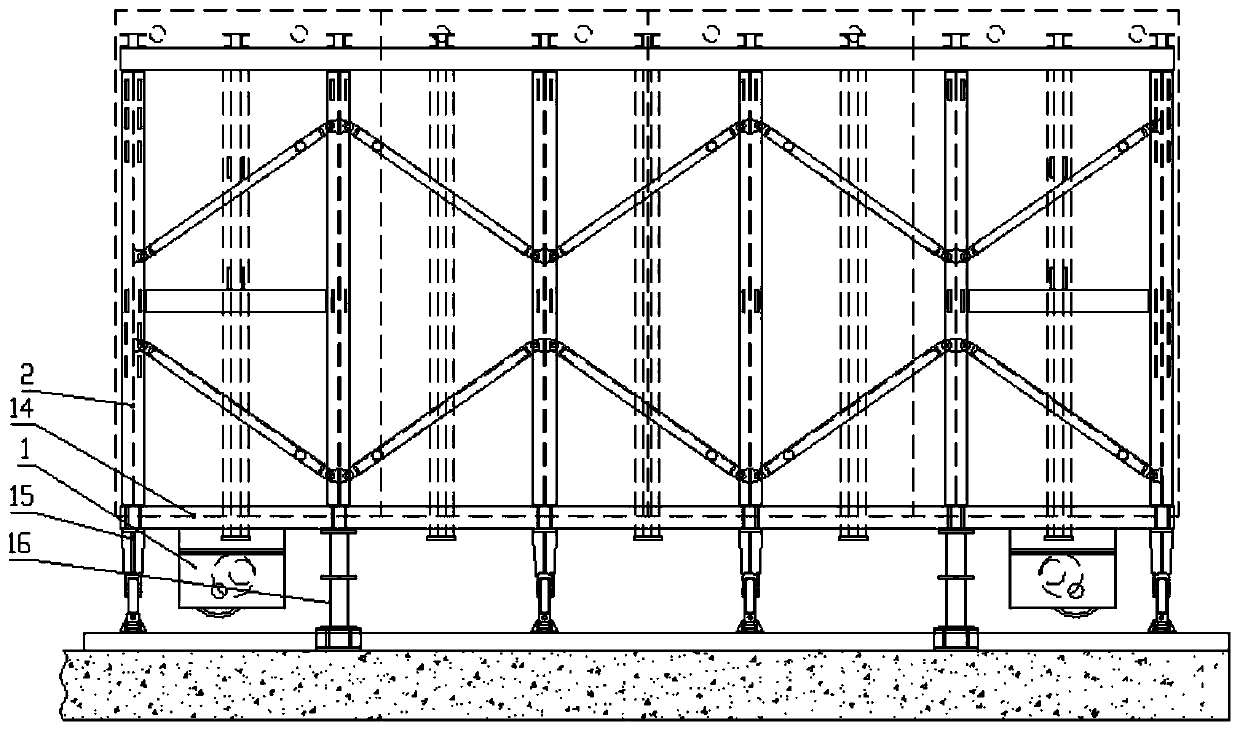

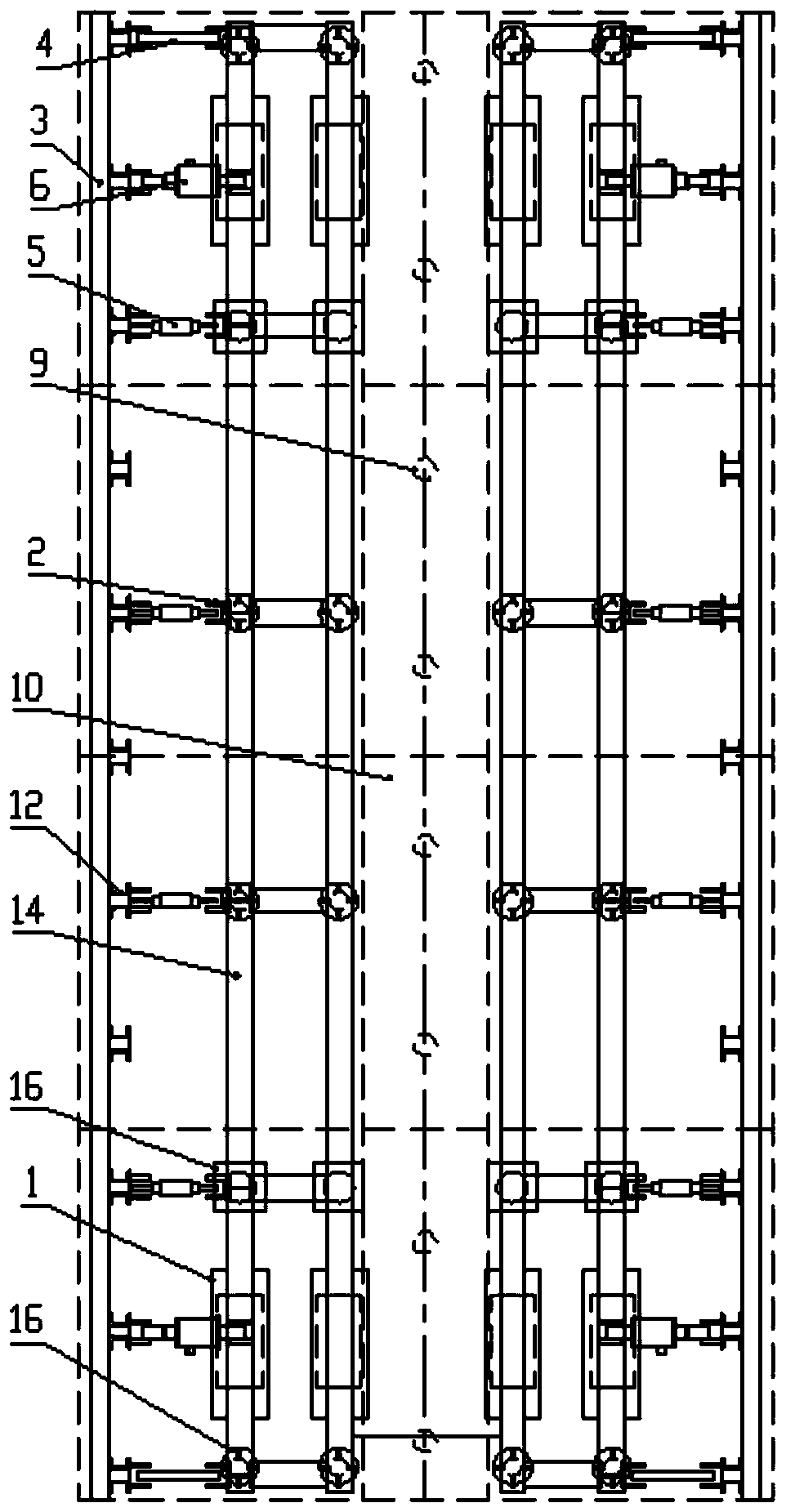

[0041]As shown in the figure, a quick support formwork for a pipe gallery according to the present invention includes a walking structure 1, a supporting structure located on the upper part of the walking, an auxiliary structure for assisting construction, and a side wall formwork 3, a top corner formwork 7, a top Side formwork 8 and top middle formwork 10.

[0042] The walking structure 1 includes a walking frame, a walking motor installed on the walking frame, and a walking wheel driven by the walking motor. The walking wheel is installed under the walking frame, and the walking motor is connected with the walking wheel through a deceleration assembly to drive the walking wheel to rotate. .

[0043] The support structure includes a support base 14, a special-shaped column 2, a positioning connector 4, a support screw 5, a demoulding cylinder 6, a side wall formwork support 12, and a top formwork support 11. Wherein, the bottom of the support base 14 is provided with the wal...

Embodiment 2

[0049] On the basis of Example 1, the construction scheme based on the rapid support formwork for the pipe gallery of Example 1 mainly includes the following steps:

[0050] Step 1: Construct the reinforced skeleton of the side walls of the pipe gallery on the floor of the poured pipe gallery, then lay the walking track on the floor surface, hoist the rapid support formwork in batches, place them on the track, and quickly support the formwork It should be used in combination with two sets;

[0051] Step 2: Assemble the fast support formwork one by one in the order from bottom to top. The specific process of assembly is: place the pre-assembled walking structure 1 and support base 14 on the track, and lift the cylinder 16 through the integral jacking structure of the auxiliary structure. And fix the lead screw 15 in place to form the bottom support, and apply an appropriate counterweight on the upper surface of the support base, then hoist the special-shaped columns 2 one by on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com