Combined box-type subgrade without bottom plate and subgrade construction method

A baseless, combined technology, applied in roads, roads, buildings, etc., can solve the problems of high construction costs and long construction time of railway subgrade engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

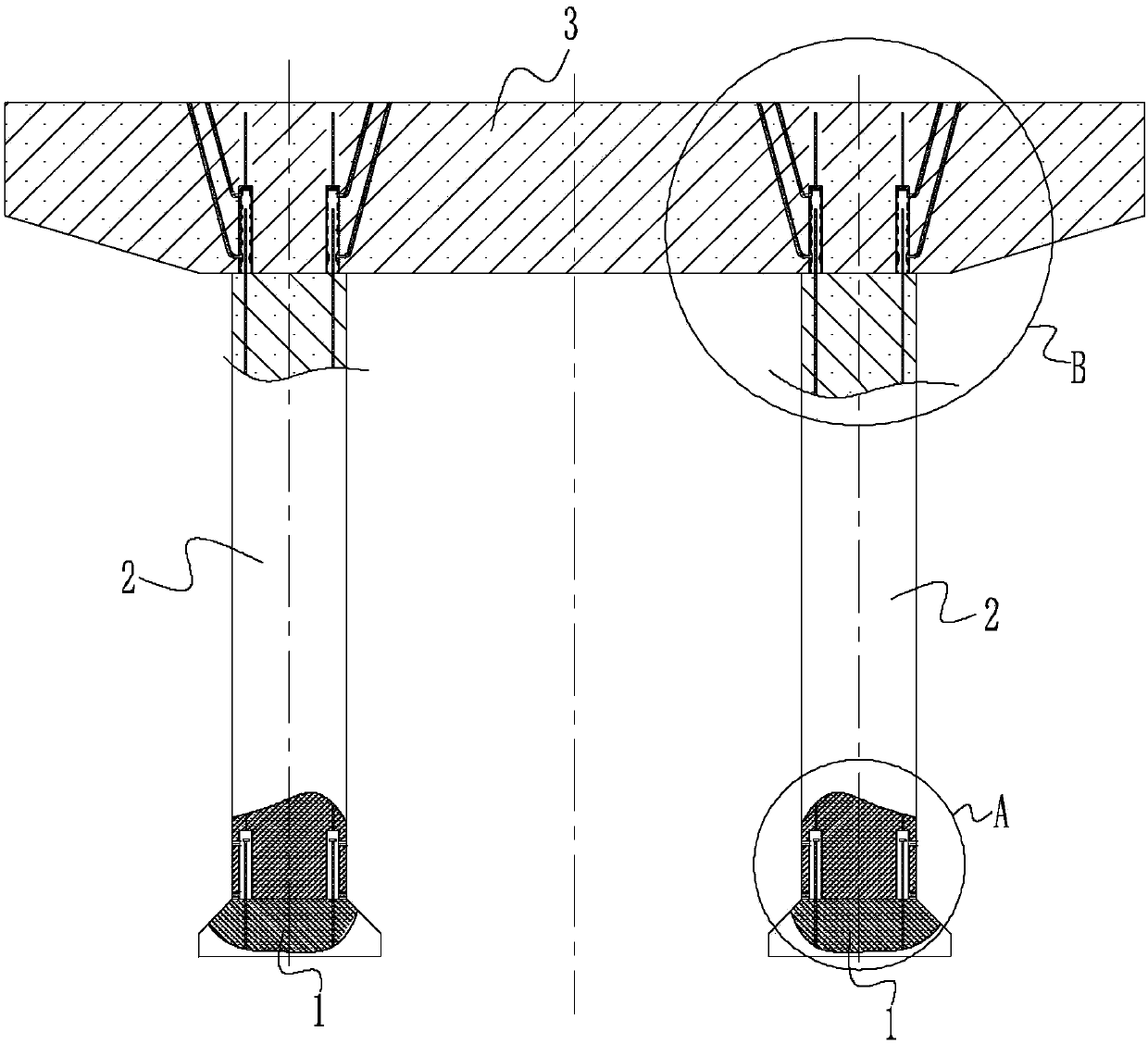

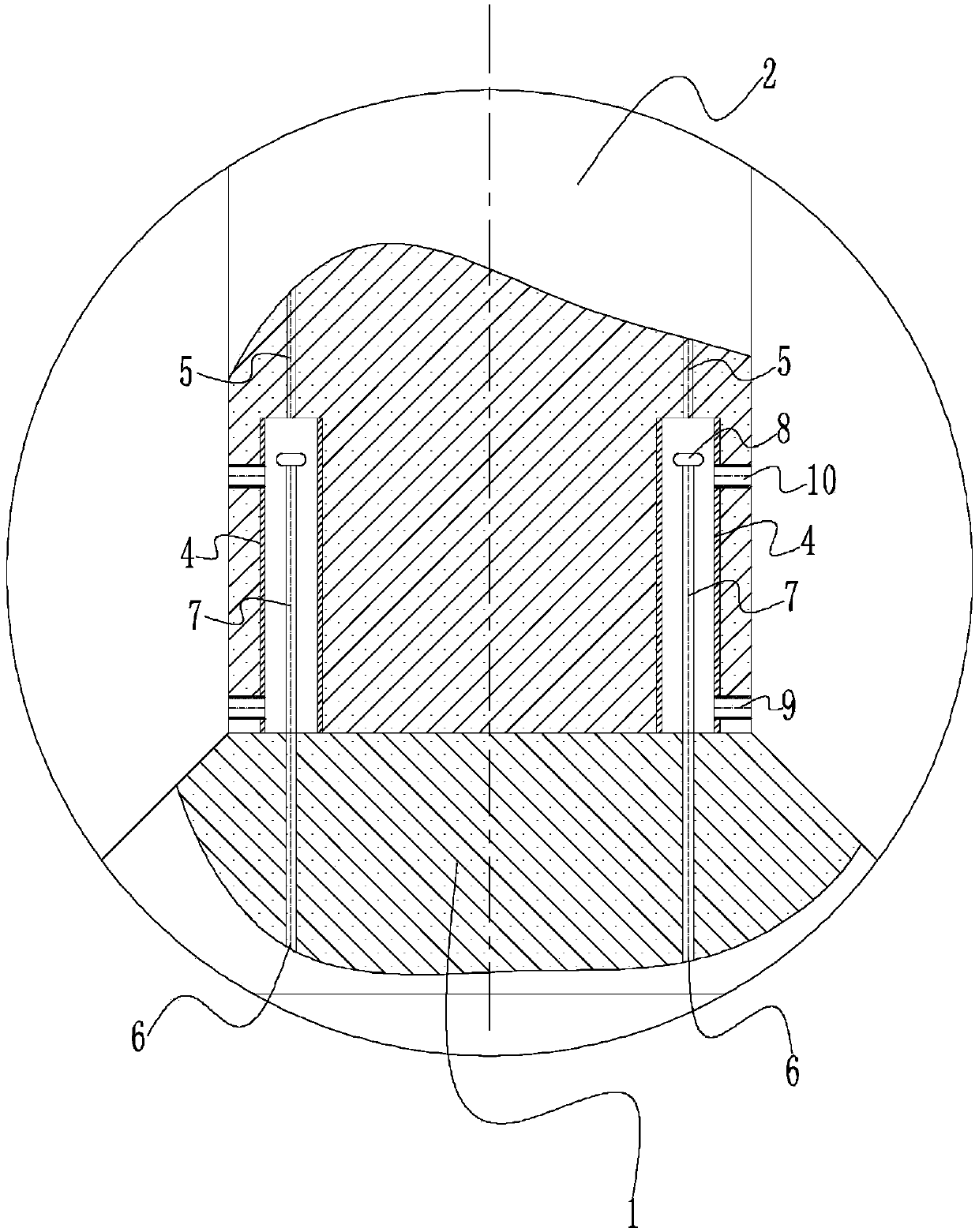

[0063] like Figure 1 to Figure 3 As shown, the combined bottomless box-type roadbed provided in this embodiment includes two caps 1, two lateral walls 2 and a roof 3, wherein the roof 3 is a prefabricated concrete slab, and the lateral wall 2 is a prefabricated concrete wall , the two lateral walls 2 are parallel to each other, the top plate 3 is located above the platform 1, and the vertical ends of each lateral wall 2 are respectively spliced with a platform 1 and the top plate 3 to form a hollow box without a bottom plate. Both sides of the bottom of the lateral wall 2 are vertically embedded with a plurality of connecting sleeves 4 with open lower ends, each connecting sleeve 4 is arranged in two rows along the length direction of the lateral wall 2, and the connecting sleeves 4 The upper end is welded or screwed to the first vertical main reinforcement 5 pre-embedded on both sides of the lateral wall 2, and the cap 1 is embedded with the second vertical main reinforcem...

Embodiment 2

[0068] like Figure 4 to Figure 6 As shown, in the combined bottomless box-type subgrade provided by this embodiment, a plurality of connecting sleeves 4 with open lower ends are vertically buried on both sides of the bottom of the lateral wall 2, and each connecting sleeve 4 is arranged along the lateral wall 2. The length direction is arranged in two rows, and the upper end of the connecting sleeve 4 is welded or screwed to the first vertical main ribs 5 embedded on both sides of the lateral wall 2, and the cap 1 is embedded with the first Two vertical main ribs 6 , when the lateral wall 2 is spliced with the platform 1 , the connecting sleeve 4 axially fits the end 7 of the second vertical main rib 6 . The inner cylinder wall of the connecting sleeve 4 is formed with a concave-convex surface. The lower end of the tube wall connecting the sleeve 4 is provided with a slurry inlet, and the wall surface of the lateral wall 2 and the slurry inlet are connected by a slurry inl...

Embodiment 3

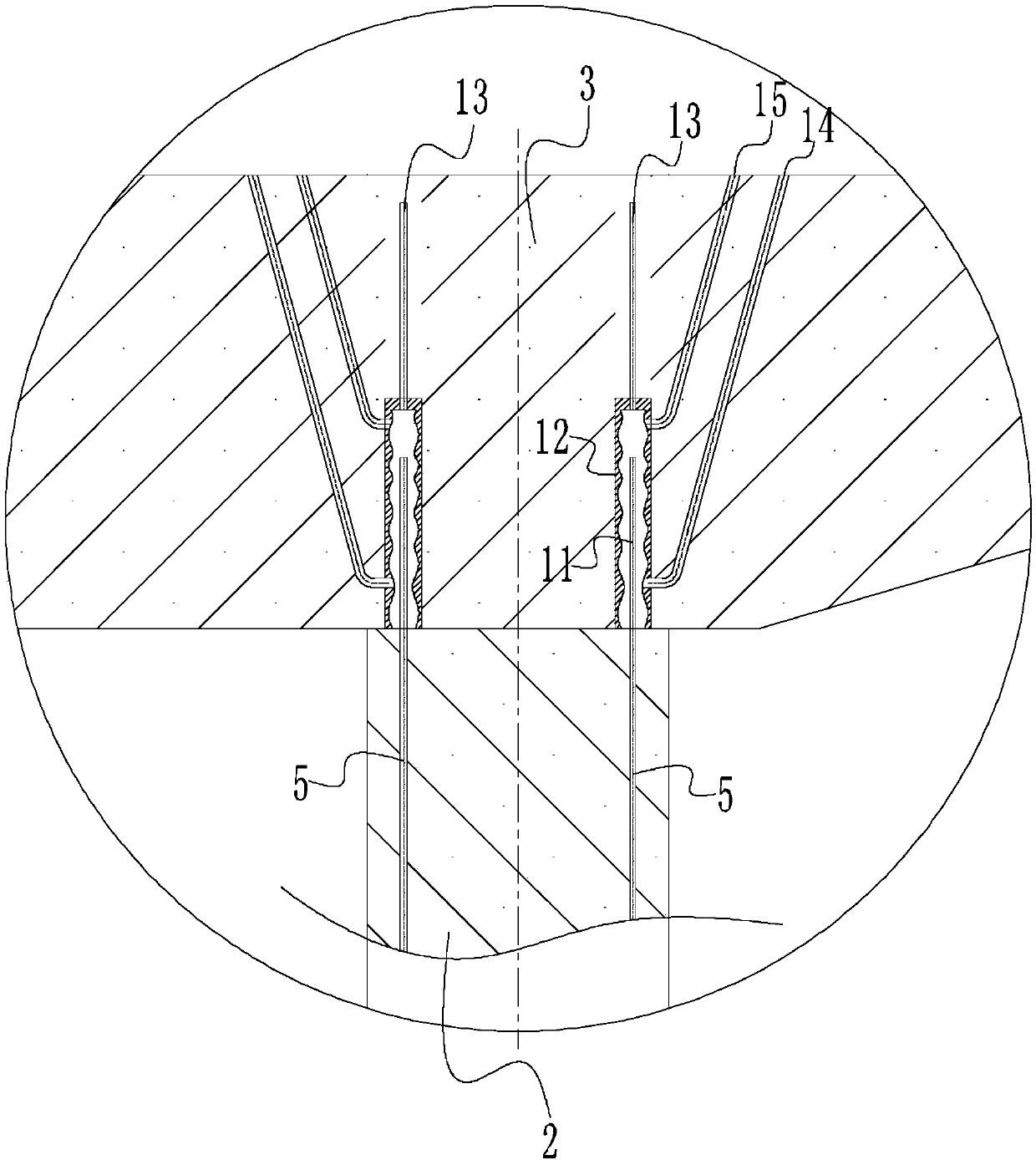

[0073] like Figure 7 As shown, the structure of the cap platform 1 and the lateral wall 2 of the combined bottomless box-type subgrade provided in this embodiment and the connection method of the two are the same as those in Embodiment 1, and will not be repeated here.

[0074] The top plate 3 is overlapped with the lateral wall 2, and the middle part of the lateral wall 2 is buried with the first vertical main rib 5 exposed at the top 11, and the corresponding position of the top plate 3 and the first vertical main rib 5 is provided with a through cast-in-place hole 16 , when the top plate 3 is overlapped with the lateral wall 2, the top 11 of the first vertical main rib 5 of the lateral wall 2 is inserted into the cast-in-place hole 16 of the roof 3, and the inner cavity of the cast-in-place hole 16 is a concave-convex surface. A portion of the top 11 of a vertical main rib 5 is bent into an L shape, and the top 11 of the first vertical main rib 5 of the lateral wall 2 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com