Textured multicolor paint and preparation method thereof

A technology of colorful paint and texture, applied in the field of paint, can solve problems such as uneven effect, uneven spraying, and paint surface blooming, etc., and achieve the effect of enhancing the toughness of color dots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] A kind of colorful texture paint, in parts by mass, the components are as follows:

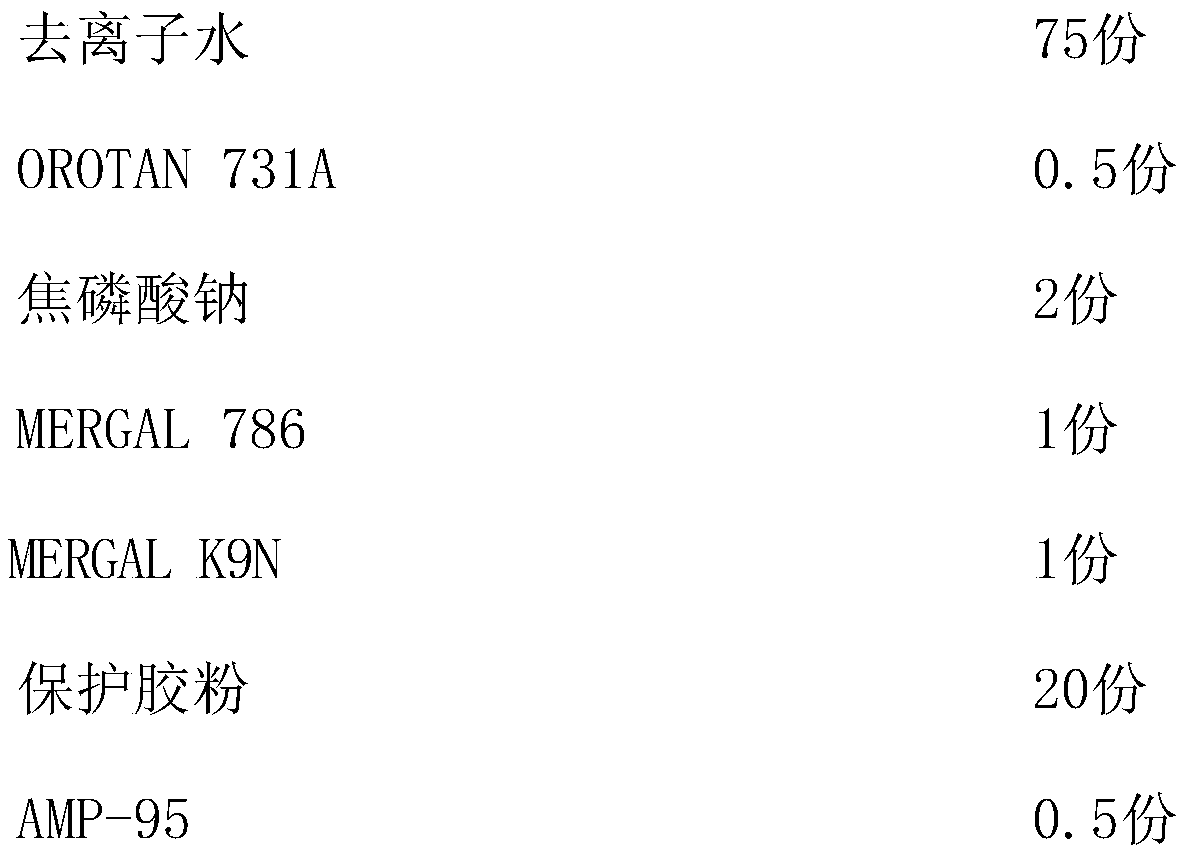

[0061] Protective glue:

[0062]

[0063] Toning base material:

[0064]

[0065]

[0066] Texture paint precursor

[0067]

[0068]

[0069] Continuous phase:

[0070]

[0071] Preparation:

[0072] (1) Preparation of protective glue for use: Add deionized water to the container and stir at a stirring speed of 300-600r / min. Add dispersant, viscosity reducer, antifungal agent, fungicide, pH regulator, and stir for 1 -2min; Adjust the stirring speed to 1300-1500r / min, add protective rubber powder and stir for 50min to prepare a protective glue slurry;

[0073] (2) Prepare the tinting base material for future use:

[0074] a. Add deionized water to the container and stir;

[0075] b. Under stirring at 300-500rpm, add mildew inhibitor and dispersant evenly and slowly and stir for 1-2min;

[0076] c. Under 600-800rpm stirring, add cellulose and stir for 5-10min;

[0077] d. Under 700-900rpm stirring, slow...

Embodiment 2

[0101] A kind of colorful texture paint, in parts by mass, the components are as follows:

[0102] Protective glue:

[0103]

[0104]

[0105] Toning base material:

[0106]

[0107]

[0108] Texture paint precursor:

[0109]

[0110] Continuous phase:

[0111]

[0112]

[0113] Preparation:

[0114] (1) Preparation of protective glue for use: Add deionized water to the container and stir at a stirring speed of 300-600r / min. Add dispersant, viscosity reducer, antifungal agent, fungicide, pH regulator, and stir for 1 -2min; Adjust the stirring speed to 1300-1500r / min, add protective rubber powder and stir for 50min to prepare a protective glue slurry;

[0115] (2) Prepare the tinting base material for future use:

[0116] a. Add deionized water to the container and stir;

[0117] b. Under stirring at 300-500rpm, add mildew inhibitor and dispersant evenly and slowly and stir for 1-2min;

[0118] c. Under 600-800rpm stirring, add cellulose and stir for 5-10min;

[0119] d. Under 700-900rpm stir...

Embodiment 3

[0143] A kind of colorful texture paint, in parts by mass, the components are as follows:

[0144] Protective glue:

[0145]

[0146] Toning base material:

[0147]

[0148]

[0149] Texture paint precursor:

[0150]

[0151] Continuous phase:

[0152]

[0153] Preparation:

[0154] (1) Preparation of protective glue for use: Add deionized water to the container and stir at a stirring speed of 300-600r / min. Add dispersant, viscosity reducer, antifungal agent, fungicide, pH regulator, and stir for 1 -2min; Adjust the stirring speed to 1300-1500r / min, add protective rubber powder and stir for 50min to prepare a protective glue slurry;

[0155] (2) Prepare the tinting base material for future use:

[0156] a. Add deionized water to the container and stir;

[0157] b. Under stirring at 300-500rpm, add mildew inhibitor and dispersant evenly and slowly and stir for 1-2min;

[0158] c. Under 600-800rpm stirring, add cellulose and stir for 5-10min;

[0159] d. Under 700-900rpm stirring, slowly add f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com