Preparation method of epoxy quaternary ammonium salt

A technology of epoxy quaternary ammonium salt and epichlorohydrin, applied in the field of antibacterial materials, can solve the problems of intensified ring opening, difficult post-processing, sudden rise in system temperature, etc., and achieves moderate reaction rate, saving energy consumption and solvent consumption. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of preparation method of epoxy quaternary ammonium salt, comprises steps as follows:

[0040] (1) When equipped with N 2 14.73g of N,N-dimethyltetradecylamine and 5ml of solvent methanol were added to the three-neck flask with protection device, thermometer, reflux condenser and magnet, and the temperature was slowly raised to 38°C.

[0041] (2) After the temperature of the system reaches 38°C, slowly add a mixture of 7.25g of epichlorohydrin and 5ml of methanol dropwise. After the dropwise addition, keep the reaction at 38°C for 6 hours, stop the reaction, and cool down to room temperature.

[0042] (3) The reaction mixture was rotary evaporated for 2 hours to remove the solvent methanol, eluted with anhydrous petroleum ether for 6-8 times, and vacuum-dried at 40° C. for 24 hours to obtain a white product.

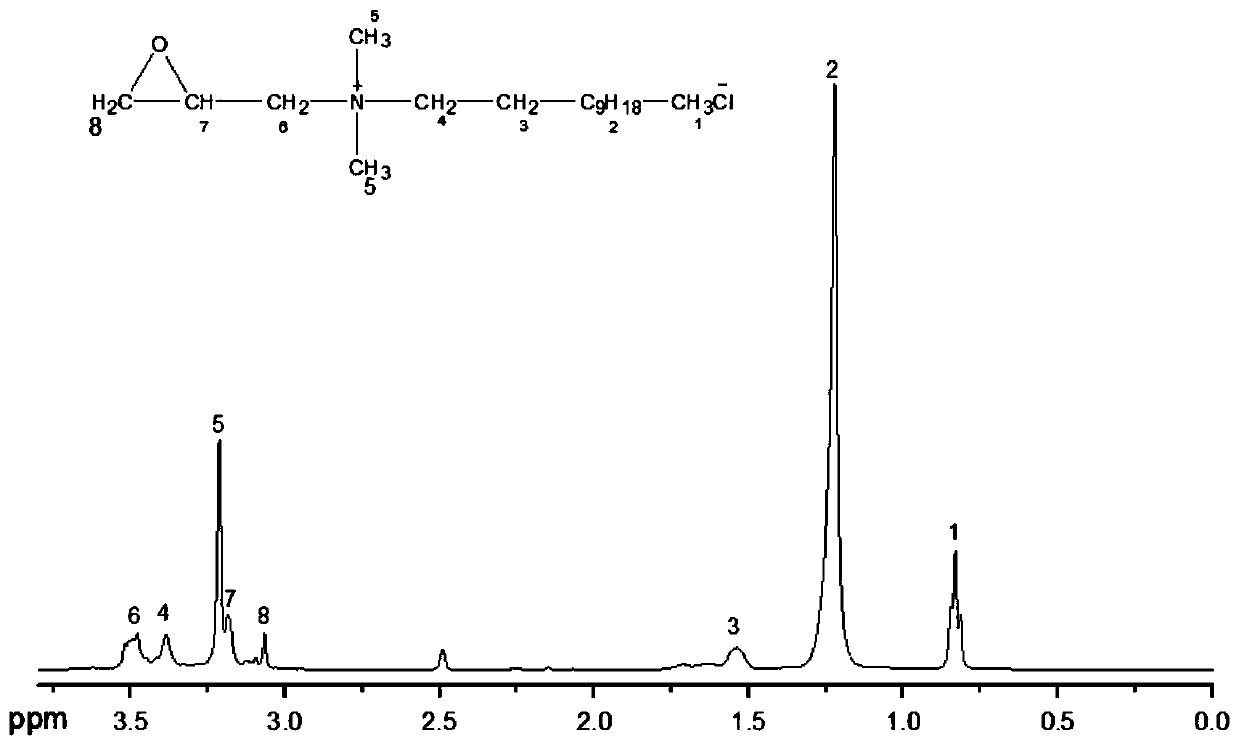

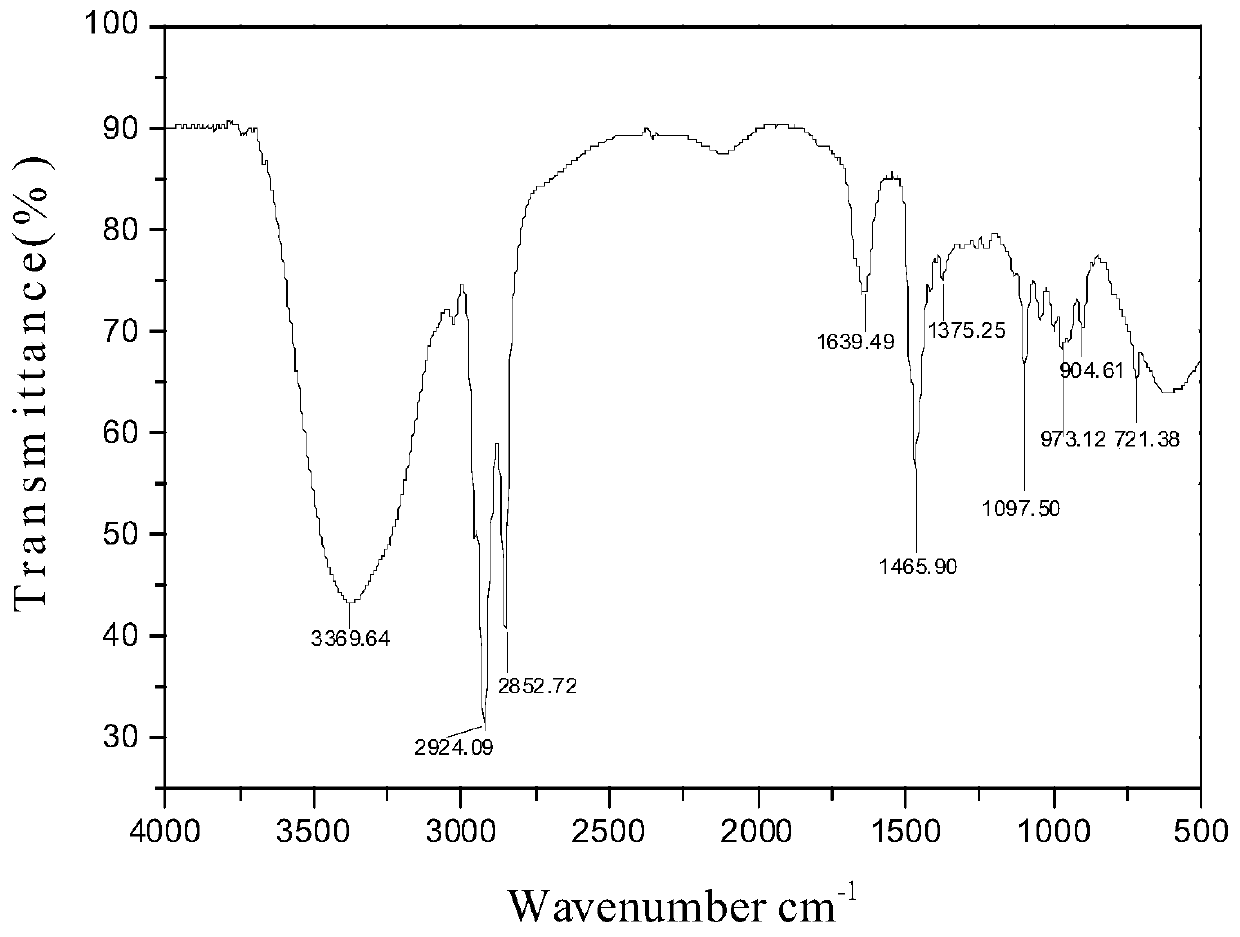

[0043] The epoxy quaternary ammonium salt 1HNMR spectrum that present embodiment obtains is as figure 1 As shown, FT-IR as figure 2 shown.

Embodiment 2

[0045] A kind of preparation method of epoxy quaternary ammonium salt, comprises steps as follows:

[0046] (1) When equipped with N 2 A certain amount of N,N-dimethylhexadecylamine (15.51 g) and solvent methanol (5 ml) were added to a three-necked flask with a protective device, a thermometer, and a reflux condenser, and the temperature was slowly raised to 38°C.

[0047] (2) After the system temperature reaches 38°C, slowly add a certain amount of epichlorohydrin (8.06g) and methanol (5ml) mixture dropwise. After the dropwise addition, keep the reaction at 38°C for 6 hours, stop the reaction, and cool down to room temperature.

[0048](3) The reaction mixture was rotatably evaporated to remove solvent methanol, eluted with anhydrous petroleum ether for 6-8 times to remove impurities, and finally vacuum-dried for 24 hours to obtain a white product of 18.83 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com