Transmission channel and vehicle-mounted security inspection system including same

A transmission channel and channel technology, which is applied in the field of object or personnel transmission, can solve problems such as errors, conveyor belt deviation, etc., and achieve the effects of small friction, saving parts, and convenient position adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

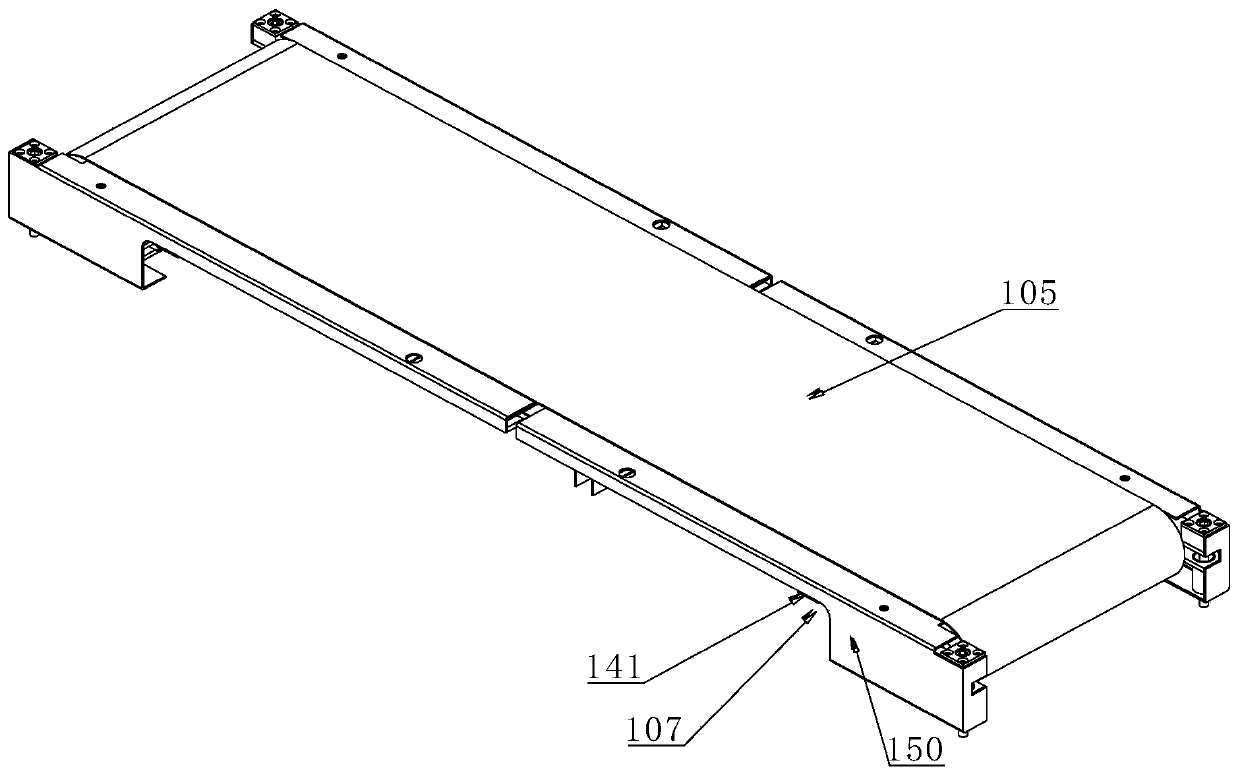

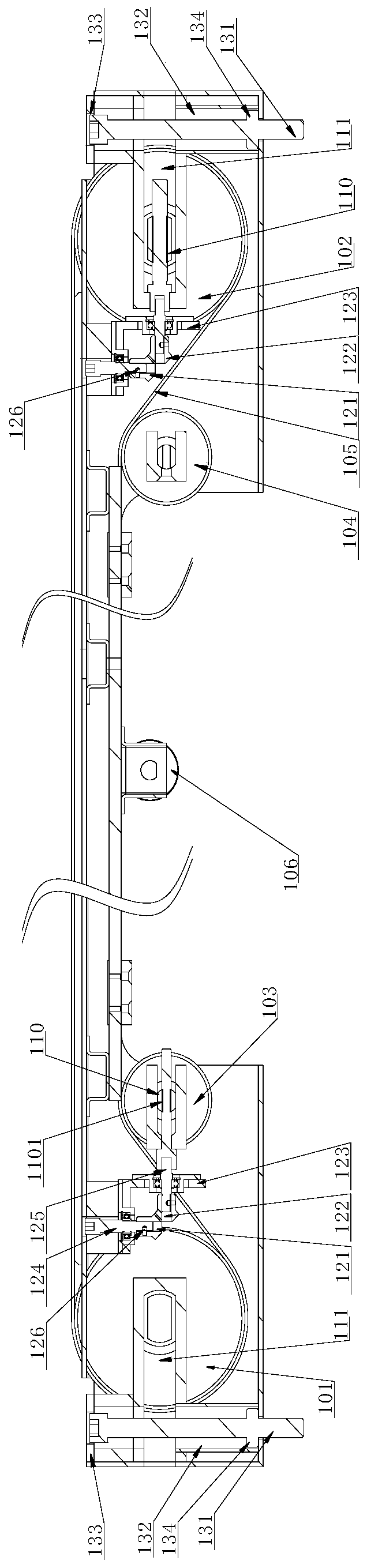

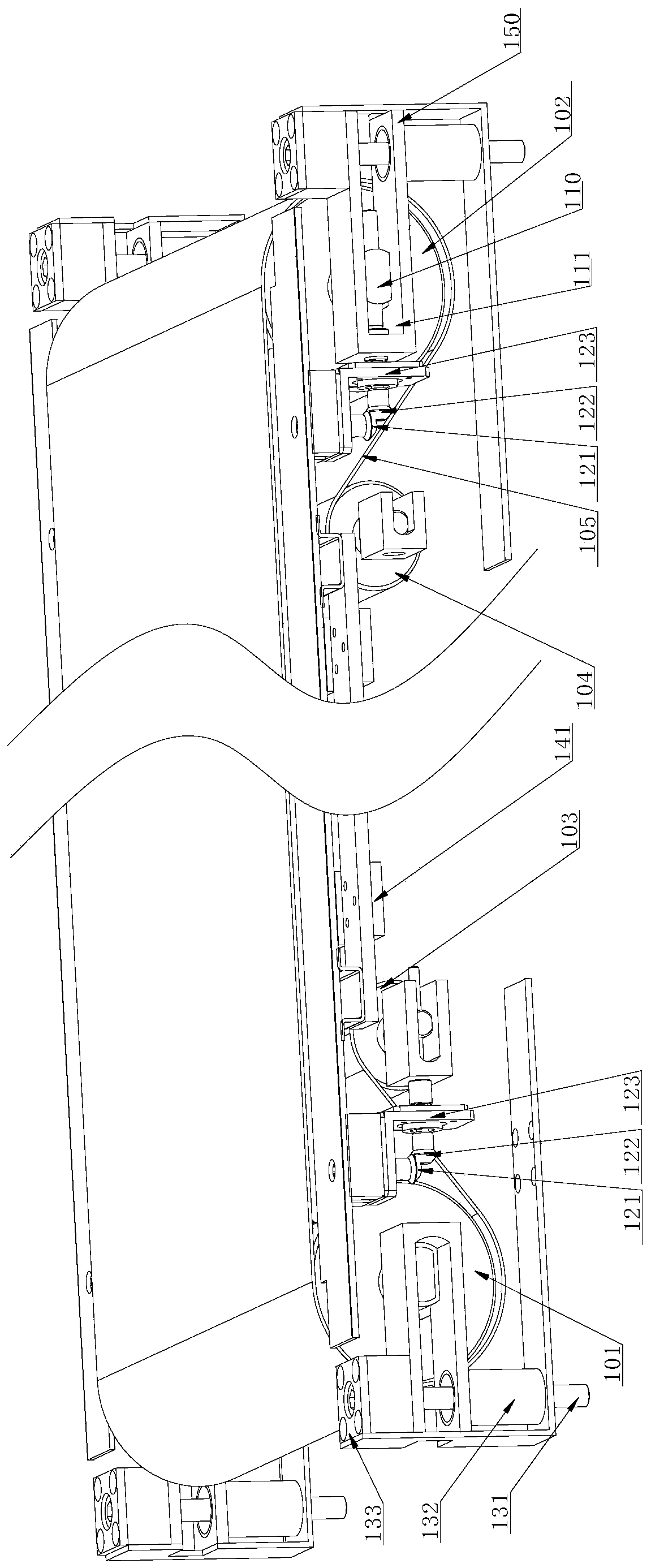

[0051] Such as Figure 1-4 As shown, a transmission channel 1 includes a closed loop conveyor belt 105, a driving roller 101 and a driven roller 102 passing through both ends of the conveyor belt 105 for supporting and driving the conveyor belt 105 to rotate, and a first guide roller 103 positioned below the conveyor belt 105 And the second guide roller 104, adjustment mechanism. The driven roller 102, the first guide roller 103 and the second guide roller 104 all include a support shaft 110, and the two ends of the support shaft 110 are arranged on the mounting frame 150, and the first guide roller 103 and the second guide roller The rollers 104 are respectively close to the driving roller 101 and the driven roller 102 ; and are located between the driving roller 101 and the driven roller 102 . The horizontal distance between the two ends of the first guide roller 103 and the driving roller 101 is adjustable, the horizontal distance between the two ends of the second guide r...

Embodiment 2

[0057] Such as Figure 5-8 As shown, the vehicle-mounted security inspection system including a transmission channel 1 described in Embodiment 1 also includes a radiation source assembly 200 and a detection assembly for human body detection. The transmission channel 1 described in Embodiment 1 is set on the radiation source assembly 200 Between the detector and the detection component, it is used to transmit the inspected person through the security check.

[0058] The radiation source assembly 200 includes a radiation source 2001 and a first support assembly for supporting the radiation source 2001. The radiation source 2001 is inclined and illuminates obliquely downward to the detector in the detection assembly. The radiation source 2001 illuminates the detection assembly obliquely downwards, so that the distance between the radiation source assembly 200 and the detection assembly will be reduced compared to the situation where the radiation source 2001 is facing directly, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com