Prefabricated panel processing equipment and processing method for ceiling heating and cooling system

A technology for refrigeration systems and processing equipment, which is applied to manufacturing tools, auxiliary forming equipment, nailing tools, etc., can solve problems such as difficulty in digging holes, affecting the installation and falling off of heating pipes or refrigeration pipes, and achieves convenient use, simple structure, Carry a lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

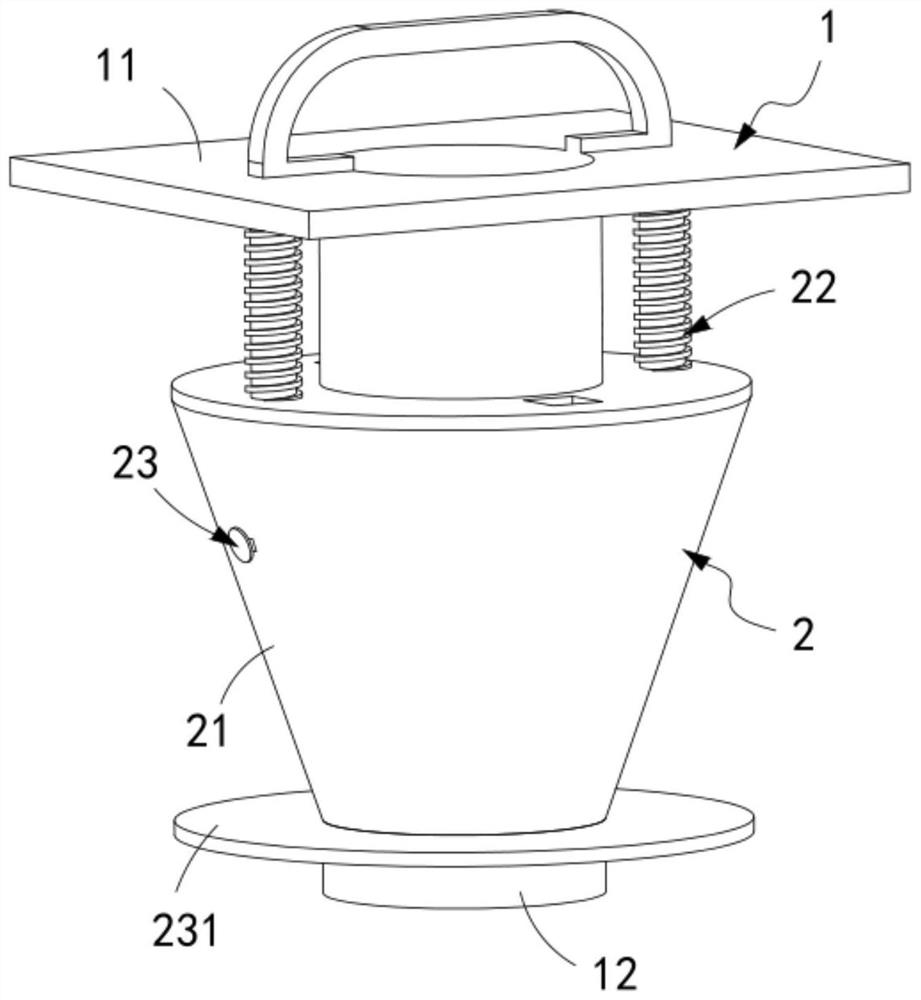

[0057] Such as figure 1 , figure 2 As shown, a prefabricated panel processing equipment for a ceiling heating and cooling system, including:

[0058] Nail-feeding mechanism 1, said nail-feeding mechanism 1 comprises a support frame 11 and a charging cylinder 12 fixedly connected with said support frame 11, nails 13 are vertically arranged in said charging cylinder 12; and a soil-filling mechanism 2, The filling mechanism 2 includes a storage bin 21 sleeved outside the charging barrel 12, an elastic assembly 22 for connecting the storage bin 21 and the support frame 11, and a control assembly for controlling the intermittent discharge of the nails 13 twenty three;

[0059] When in use, the elastic component 22 is in the original long state, and the lower surface of the control component 23 is arranged in contact with the prefabricated plate 3;

[0060] When the elastic component 22 is in a compressed state, the lower surface of the control component 23 is still in contact w...

Embodiment 2

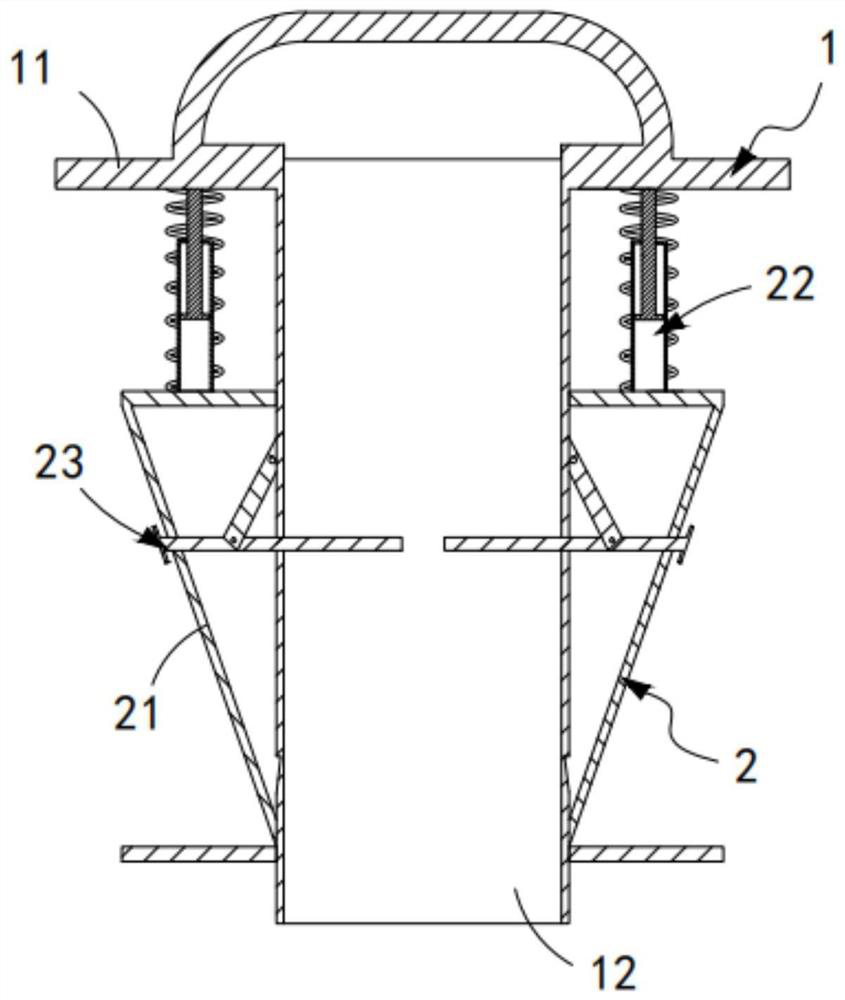

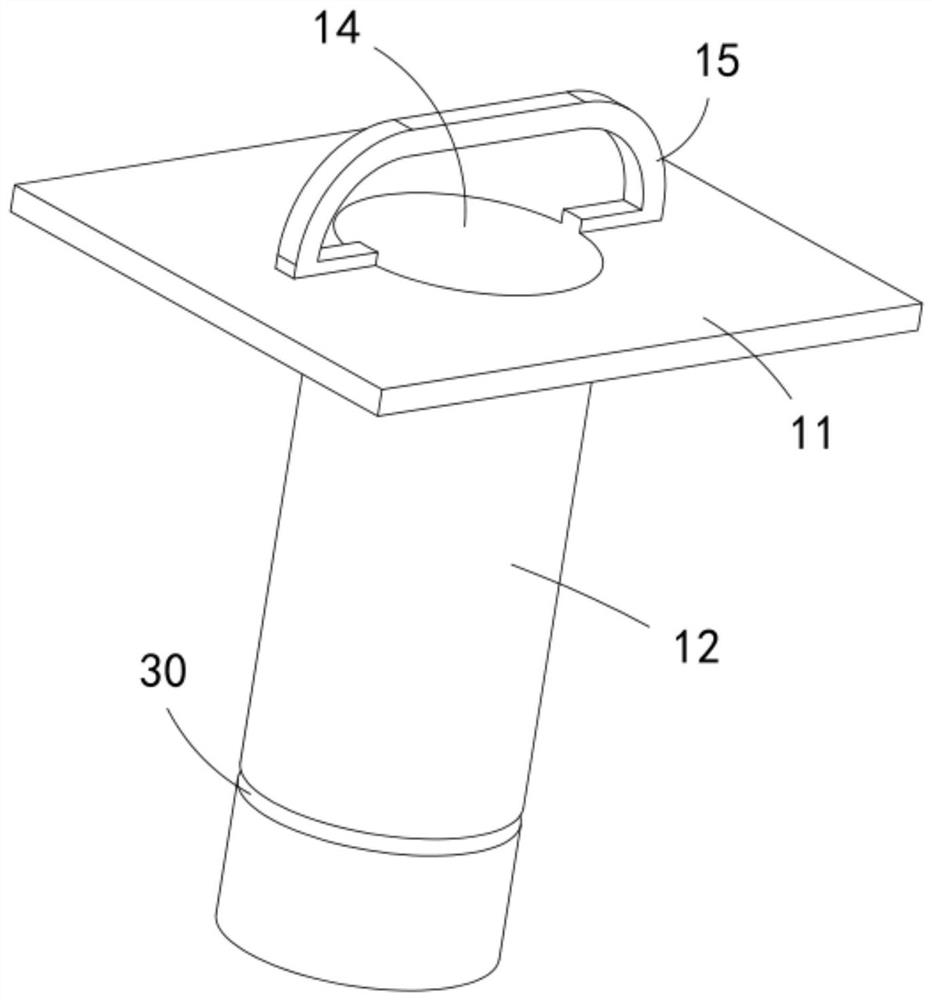

[0087] Such as Figure 8 , Figure 9 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0088] further, such as Figure 8 , Figure 9 As shown, the groove 30 is arranged around the side wall of the charging tube 12 , and the distance from the side wall of the charging tube 12 to the inner wall of the charging tube 12 is shortened from top to bottom.

[0089] In this embodiment, by setting the groove 30, the distance from the side wall of the charging barrel 12 to the inner wall of the charging barrel 12 is shortened from top to bottom, so that the mud outlet channel gradually increases, and then the flow rate of the cement reaching the port is increased. The bigger it is, the faster it f...

Embodiment 3

[0091] Such as Figure 13 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment three and embodiment one is:

[0092] A method for processing prefabricated panels for a ceiling heating and cooling system, comprising:

[0093] Step 1, select the material, take a prefabricated board 3 with uncured cement, and install the prefabricated board 3 to install the heating pipe or the cooling pipe 50;

[0094] Step 2, digging pits, and carrying out the digging work of several groups of nail pits at equal intervals along the track where heating pipes or cold pipes 50 are installed;

[0095] Step 3, setting the trajectory, connecting and fixing the manipulator with the handle 15, and controlling the movement of the nail pit trajecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com