Starch canning equipment

A technology of canning and equipment, applied in the field of starch canning equipment, can solve the problems of consuming more manpower and time, slow filling speed, low work efficiency, etc., and achieve the effect of improving practicability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

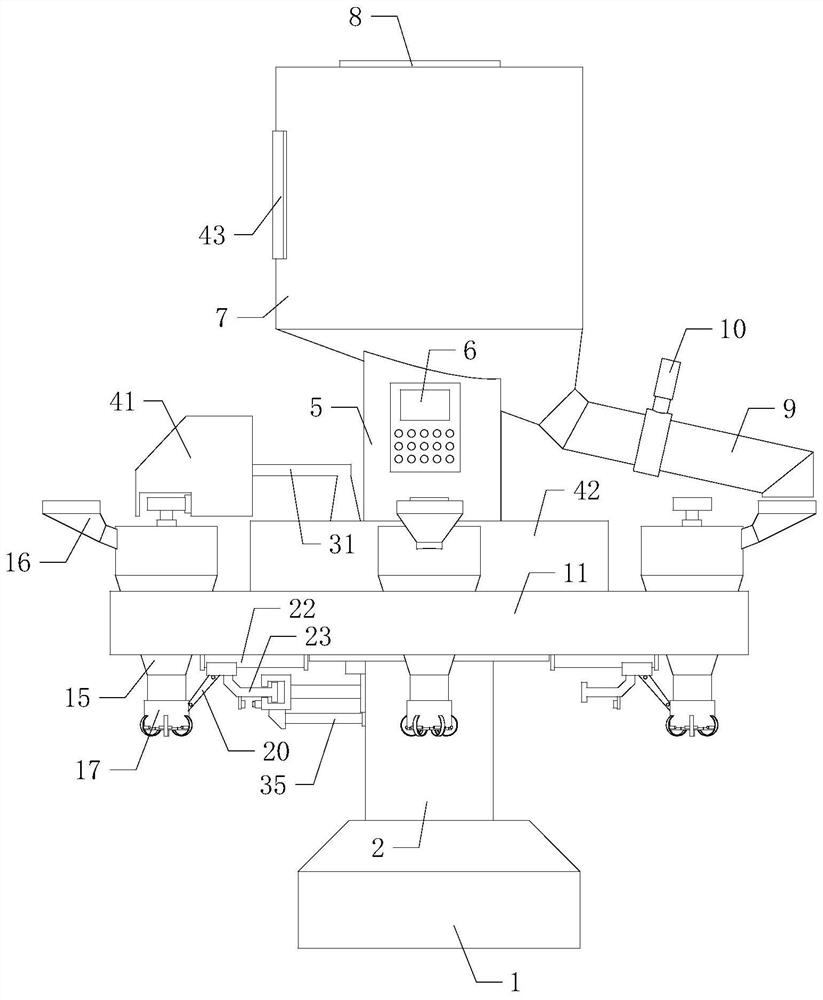

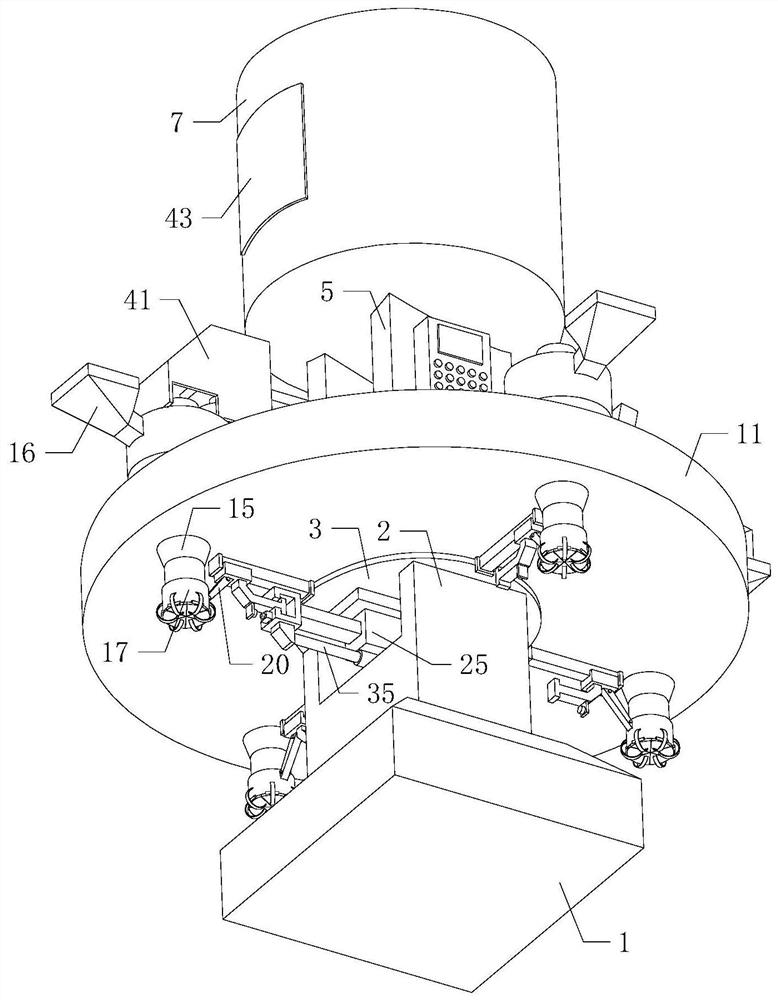

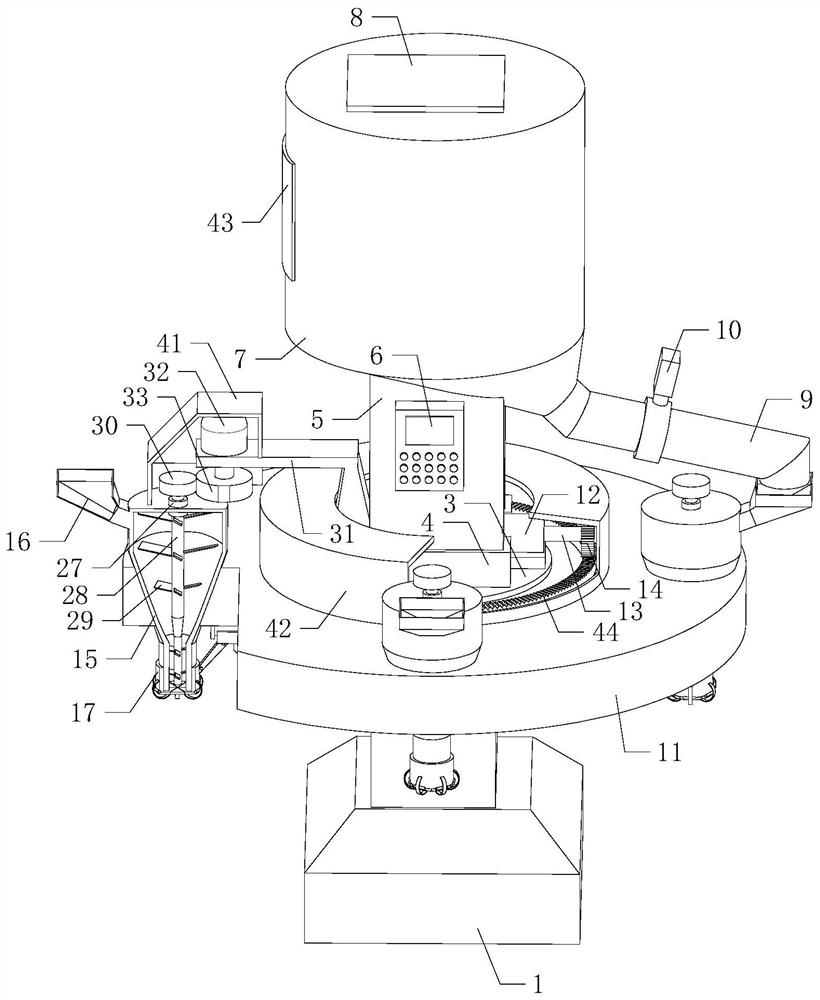

[0015] The specific embodiments of the present invention will be described in further detail with reference to the following drawings and examples. The following examples are used to illustrate the invention, but not to limit the scope of the invention.

[0016] such as 1 to 4As shown, when the starch canning equipment of the present invention works, the central control box 6 controls to open the electromagnetic switch valve 10, the starch stored in the material box 7 can enter the right feed hopper 16 through the material guide channel 9, and the starch in the right feed hopper 16 naturally slides into the right feed hopper 15. Two groups of pressure scales 4 monitor the total amount of starch in the two groups of vertical plates 5, the material box 7 and the material box 7 in real time and transmit the detection signal to the central control box 6. When the weights detected by the two groups of pressure scales 4 drop to the specified value, the central control box 6 controls to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com