Novel water-cooling shield device

A water-cooling and shielding technology, which is applied in the field of new water-cooling shielding devices, can solve the problems of weld tearing at the opening position, rectangular steel pipes are easily damaged and deformed by baking, and water leakage, etc., so as to improve the service life, facilitate manufacture and maintenance, The effect of reducing the probability of water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

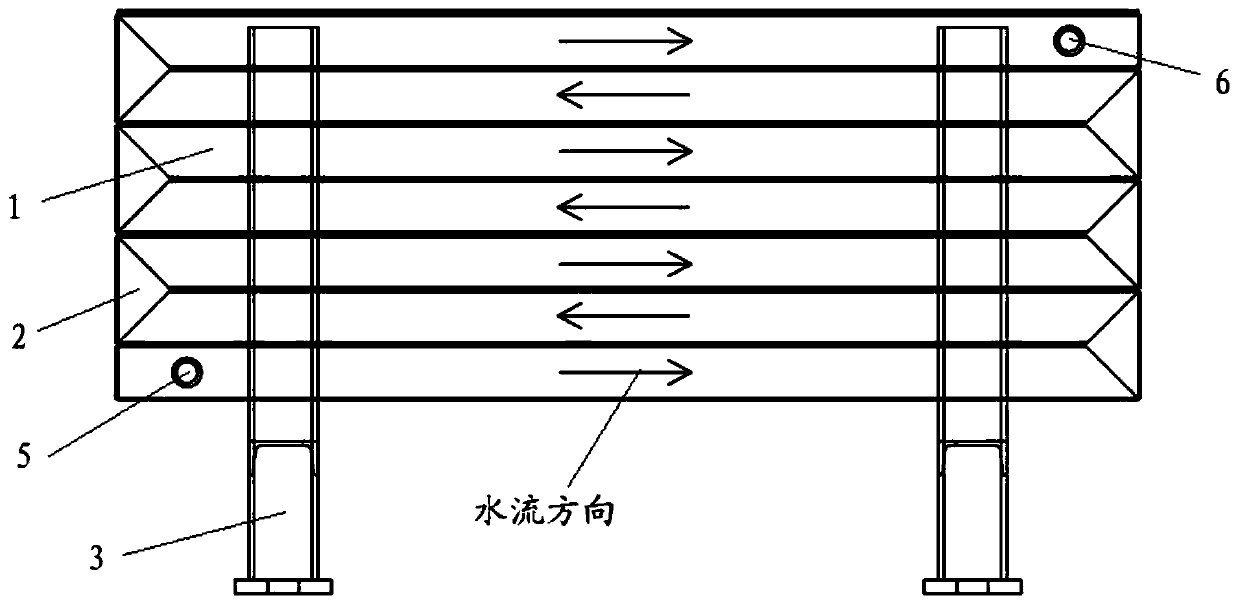

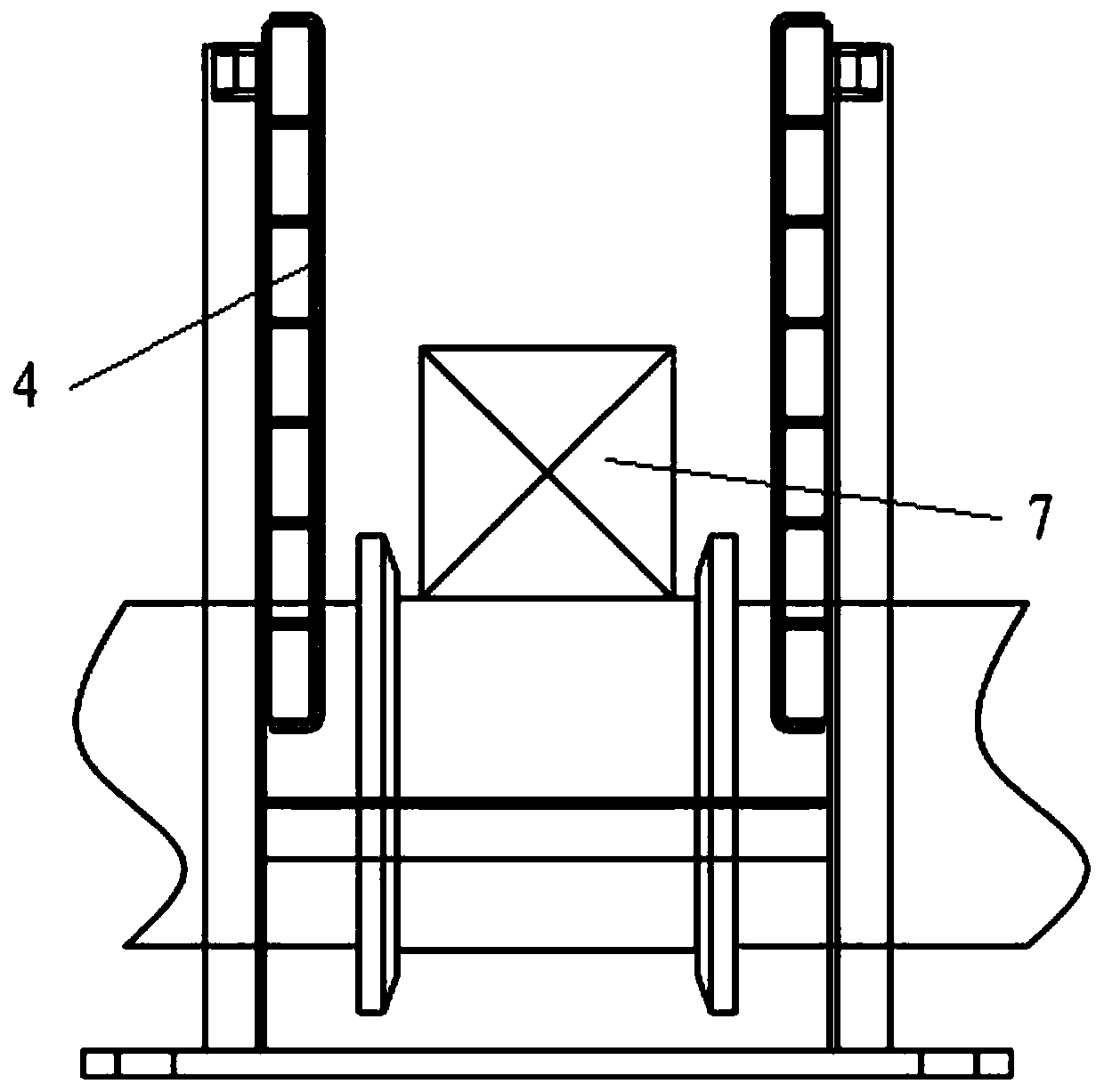

[0027] The embodiment of the present invention provides a new type of water-cooled shroud device, please refer to Figure 1 to Figure 3 , the device includes:

[0028] Bracket 3;

[0029] One piece of rectangular steel pipe, and two pieces of rectangular steel pipe are symmetrically arranged on the support 3; wherein, one piece of rectangular steel pipe includes:

[0030] Rectangular steel pipe 1, several rectangular steel pipes 1 are arranged on the support 3;

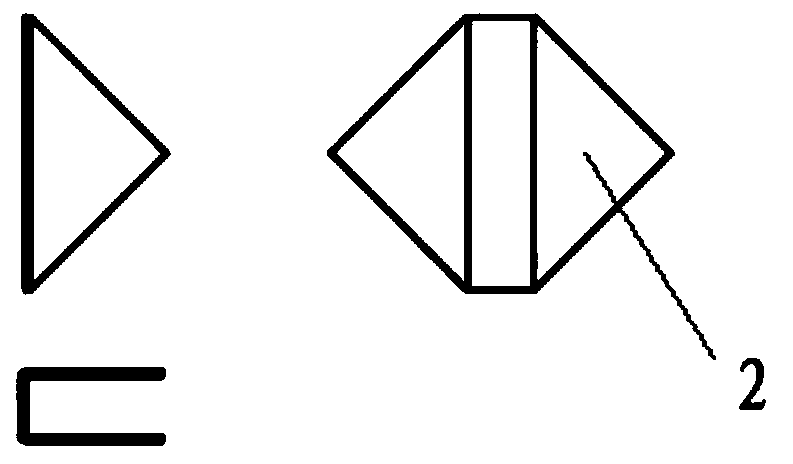

[0031] A guide plate 2, the guide plate 2 is arranged at the same port of two adjacent rectangular steel pipes 1;

[0032] A water inlet 5, the water inlet 5 is arranged at the lower left corner of one piece of the rectangular steel pipe;

[0033] A water outlet 6, the water outlet 6 is arranged on the upper right corner of one piece of rectangular steel pipe;

[0034] The heat insulation board 4 is arranged on the inside of the rectangular steel pipe 1 .

[0035] Further, the rectangular steel pipe 1 is a hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com